carbon backed tube cosno 3 Granular structure material and its preparation method and application

A technology of granular structure and nanostructure, applied in structural parts, electrical components, electrochemical generators, etc., can solve problems such as low tap density, and achieve improved tap density, high volume energy and power density, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

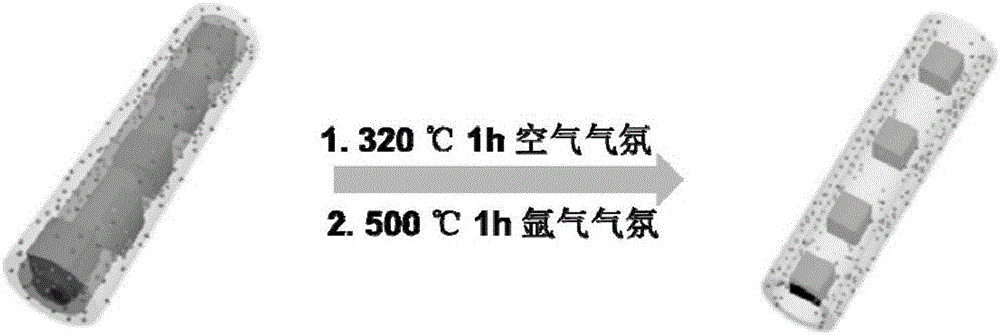

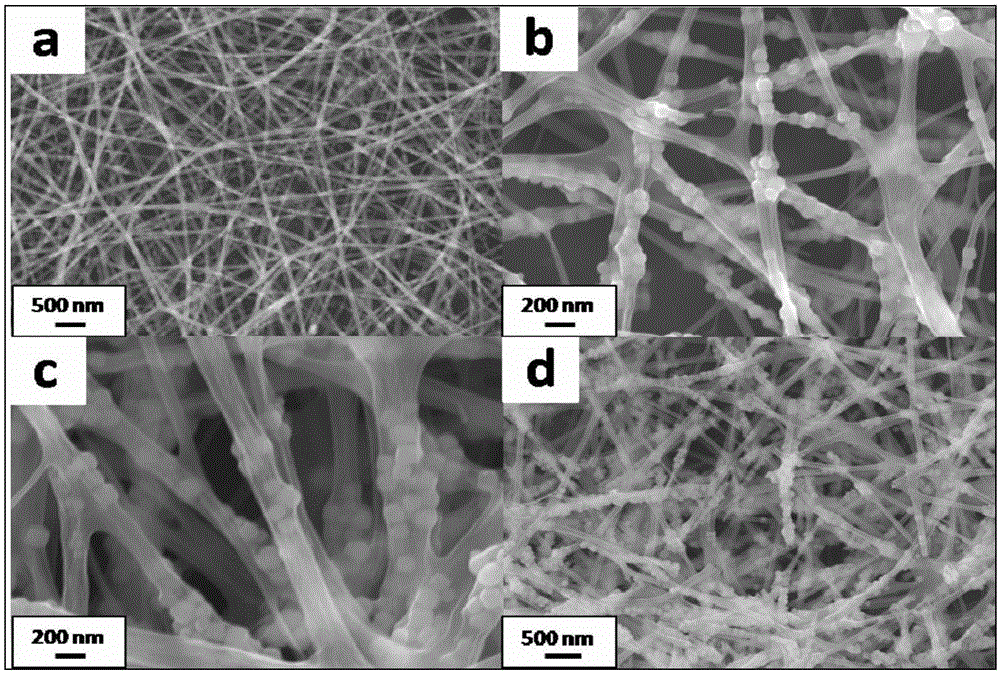

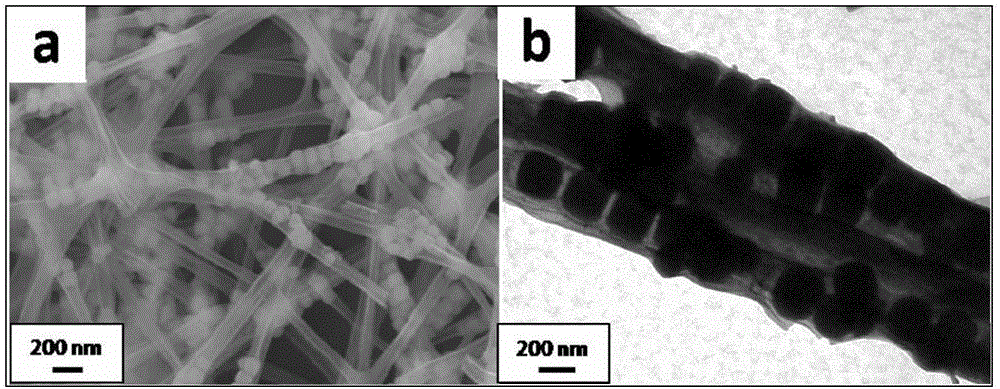

[0030] (CoSnO 3 (particles)@MnO@Mn 3 o 4 @C (Tube) Particle Nanomaterials in Tube)

[0031] 1) Weigh 700mg of CoSn(OH) 6 Nanoparticles were added to 20mL deionized water and ultrasonically dispersed for 10min to make them evenly dispersed, then 0.6g, 0.8g, 1.0g of high, medium and low molecular weight polyvinyl alcohol (PVA) and 1.5g of manganese acetate tetrahydrate were taken respectively, At the same time, add it to the above solution, and heat it in a water bath with magnetic stirring to dissolve it completely, forming an electrospinning solution with a certain viscosity;

[0032] 2) Add the electrospinning solution in step 1) to the injection, and perform electrospinning under the conditions of positive high voltage 12kV and negative high voltage ‐2kV, with a push speed of 0.02mm / min, and receive nanofibers with aluminum foil on the drum;

[0033] 3) Place the spun fiber obtained in step 2) in a 120°C oven for vacuum drying for 5 hours;

[0034] 4) The composite nano...

Embodiment 2

[0043] (CoSnO 3 (Particles) @CoO x @MnO x @C (tube) (Co:Mn=1:2) particle nanomaterial in tube)

[0044] 1) Weigh 700mg of CoSn(OH) 6 Nanoparticles were added to 20mL deionized water, and ultrasonically dispersed for 10min to make them uniformly dispersed, then 0.6g, 0.8g, 1.0g of high, medium and low molecular weight polyvinyl alcohol (PVA), 0.498g of cobalt acetate tetrahydrate and 0.980g of manganese acetate tetrahydrate was added to the above solution at the same time, and it was heated and magnetically stirred in a water bath to dissolve it completely, forming an electrospinning solution with a certain viscosity.

[0045] 2) Add the electrospinning solution in step 1) to the injection, and perform electrospinning under the conditions of positive high voltage 12kV and negative high voltage ‐2kV, with a push speed of 0.02mm / min, and receive nanofibers with aluminum foil on the drum;

[0046] 3) Place the spun fiber obtained in step 2) in a 120°C oven for vacuum drying fo...

Embodiment 3

[0050] (CoSnO 3 (Particles) @CoO x @MnO x @C (tube) (Co:Mn=2:1) particle nanomaterial in tube)

[0051] 1) Weigh 700mg of CoSn(OH) 6 Nanoparticles were added to 20mL deionized water, and ultrasonically dispersed for 10min to make them uniformly dispersed, then 0.6g, 0.8g, 1.0g of high, medium and low molecular weight polyvinyl alcohol (PVA), 0.996g of cobalt acetate tetrahydrate and 0.491g manganese acetate tetrahydrate is added into the above-mentioned solution simultaneously, and it is heated and magnetically stirred in a water bath to make it all dissolve, forming an electrospinning solution with a certain viscosity;

[0052] 2) Add the electrospinning solution in step 1) to the injection, and perform electrospinning under the conditions of positive high voltage 12kV and negative high voltage ‐2kV, with a push speed of 0.02mm / min, and receive nanofibers with aluminum foil on the drum;

[0053] 3) Place the spun fiber obtained in step 2) in a 120°C oven for vacuum dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com