Vacuum prepressing method having alternating type air exhaust

An alternate, vacuum technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as the inability to fundamentally solve the problem of clogging, and achieve the advantages of delaying the clogging time, simple equipment operation, and alleviating clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

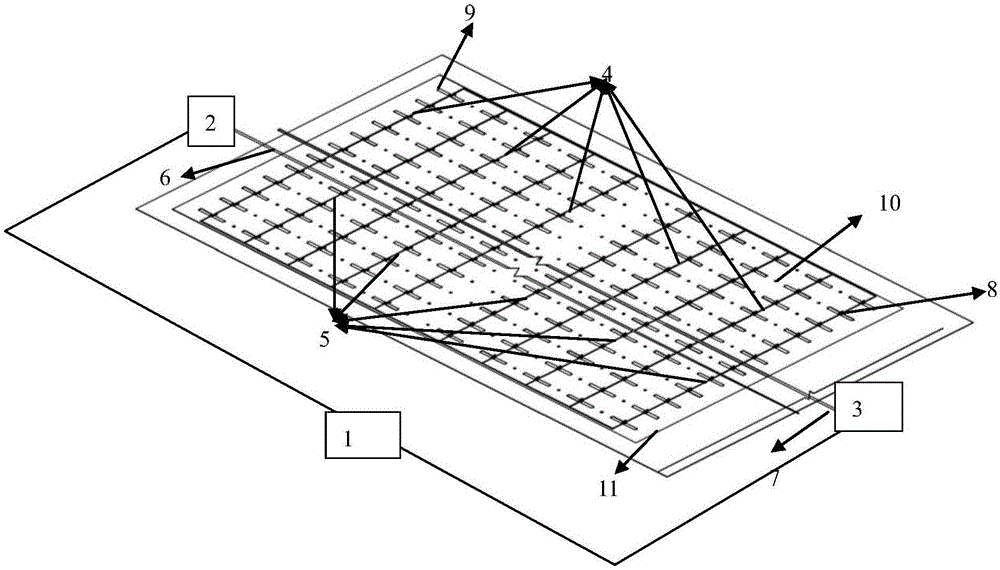

[0019] see figure 1 , the present invention discloses a vacuum preloading method of alternate pumping, which includes a vacuum preloading system and a system control system, wherein the odd and even numbers mentioned in the text are according to the number of rows of branch pipes from the first row to the last row Defined.

[0020] The vacuum preloading system includes odd-numbered drainage branch pipes 4, even-numbered drainage branch pipes 5, first main pipe 6, second main pipe 7, bow tie 8, drainage plate 9, gas injection pipe 10, and vacuum membrane 11. First lay vacuum film 11 on the soft soil foundation, and the bow ties 8 in odd rows are respectively connected to drainage boards 9 and odd drainage branch pipes 4, and odd number drainage branch pipe jet pump 3 controls the first main pipe 6 to pump air. Similarly, the bow ties 8 in the even rows are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com