Tail gas desulfuration adopting zinc oxide method in smelting industry

A technology of zinc oxide and tail gas, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as abnormal operation of the project, wear and tear of system pipes and pumps, blockage of equipment and pipes, etc., and promote clean production. , ease wear, reduce the effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

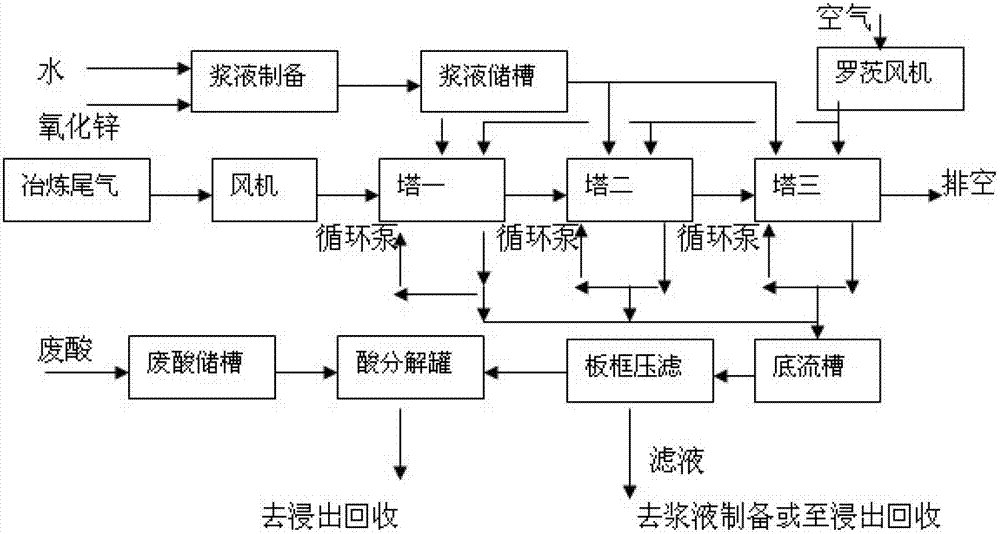

[0058] Such as figure 1 The process steps shown, (1) Slurry preparation: Mix water and zinc oxide dust to make slurry. The soluble zinc oxide content in the zinc oxide dust is 60%, and the solid content of the zinc oxide dust is 20%. Put the prepared slurry into Reserved in the storage tank;

[0059] (2) Increase the pressure of smelting tail gas: pass the smelting tail gas to be treated at a temperature of 0-300°C into the booster fan, the flow rate of the fan matches the amount of flue gas, and the wind pressure reaches 6000Pa;

[0060] (3) Absorption process: The number of absorption towers is determined according to the concentration of sulfur dioxide in the tail gas. The content of sulfur dioxide in the tail gas is 0-6000mg / Nm 3 Within the range, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com