Anti-blocking heat exchanging device for pulverized coal boiler air pre-heater

A pulverized coal boiler and heat exchange device technology, applied in the field of boiler heat exchange, can solve the problems of air preheater clogging, corrosion, etc., achieve the effects of reducing exhaust gas temperature, ensuring boiler efficiency, and alleviating air preheater clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and specific embodiments.

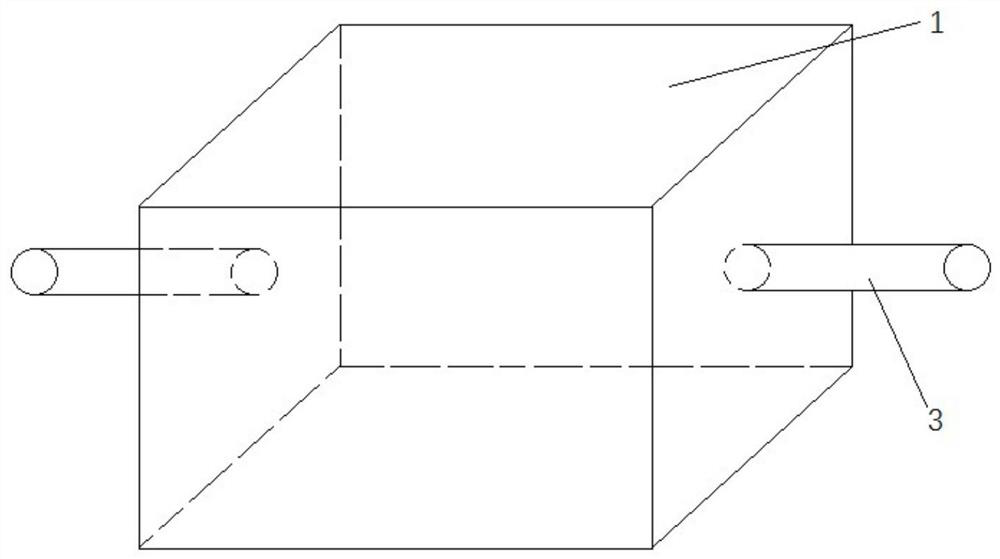

[0019] An anti-blocking heat exchange device for the air preheater of a pulverized coal boiler, such as figure 1 As shown, the main body 1 is included. The two ends of the main body 1 are provided with pipes 3, and the pipes 3 are connected to the dust collector and the induced draft fan. A number of heat exchanger unit modules 2 are divided into the main body.

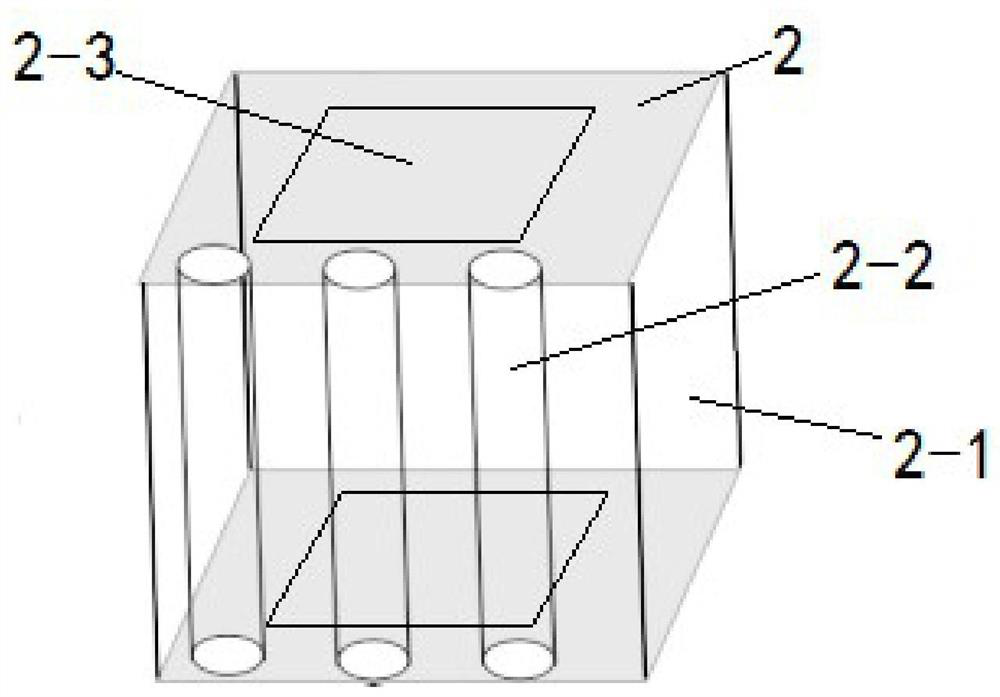

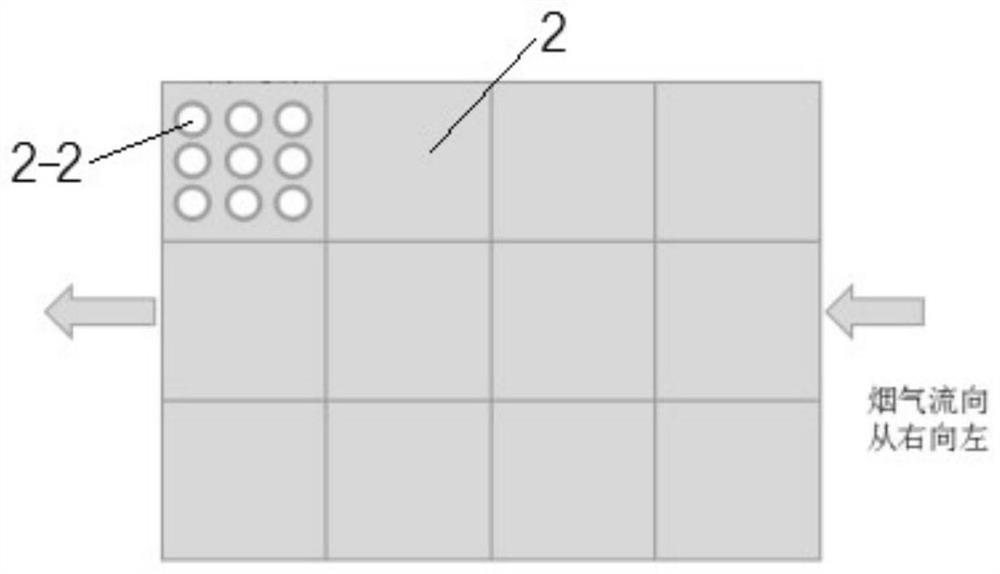

[0020] Such as figure 2 , 3 As shown, the heat exchanger unit module 2 includes an outer frame 2-1, the outer frame 2-1 is a cube or cuboid structure, the two ends of the outer frame 2-1 are flues, and the outer frame 2-1 is provided with a hollow cylinder 2 -2. The opening direction of the flue at both ends of the outer frame 2-1 is the same as the installation direction of the pipe 3, the installation direction of the hollow cylinder 2-2 is perpendicular to the installation direction of the pipe 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com