Microalgae concentrating and collecting method and device thereof

A technology for microalgae and collection ponds, applied in microorganism-based methods, methods of supporting/immobilizing microorganisms, methods of sterilization, etc., can solve the problems of high energy consumption, high cost, algae decay, etc. Energy consumption and the effect of relieving filter membrane blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

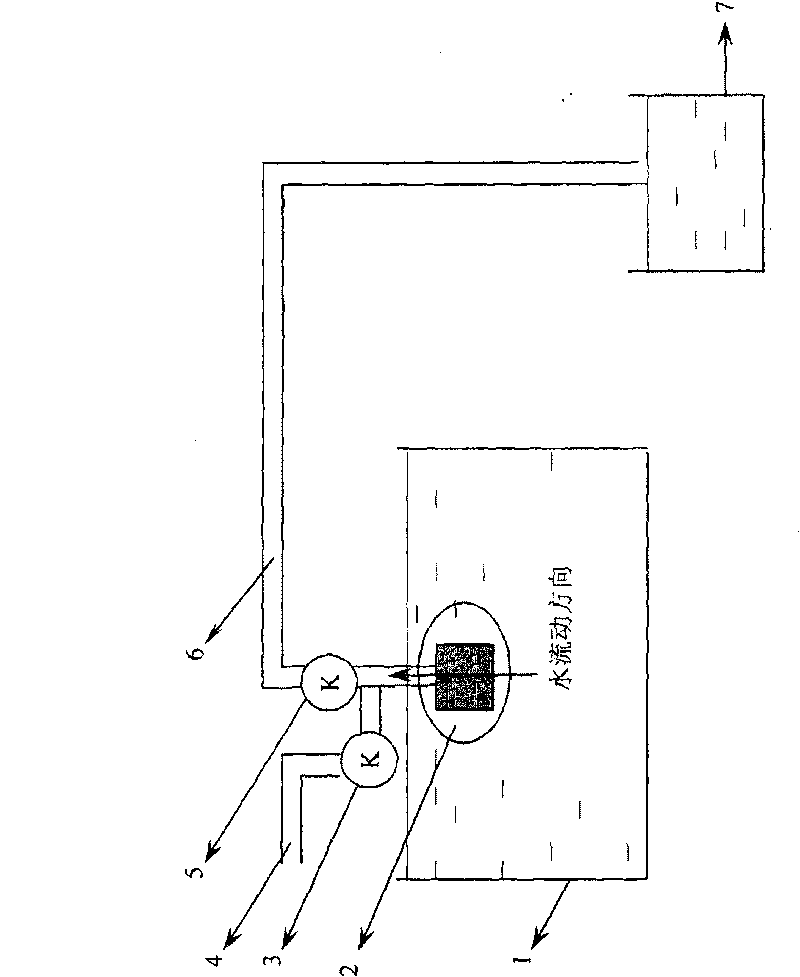

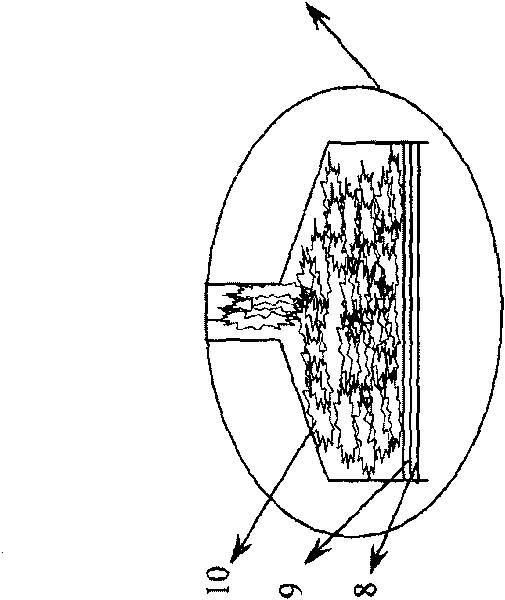

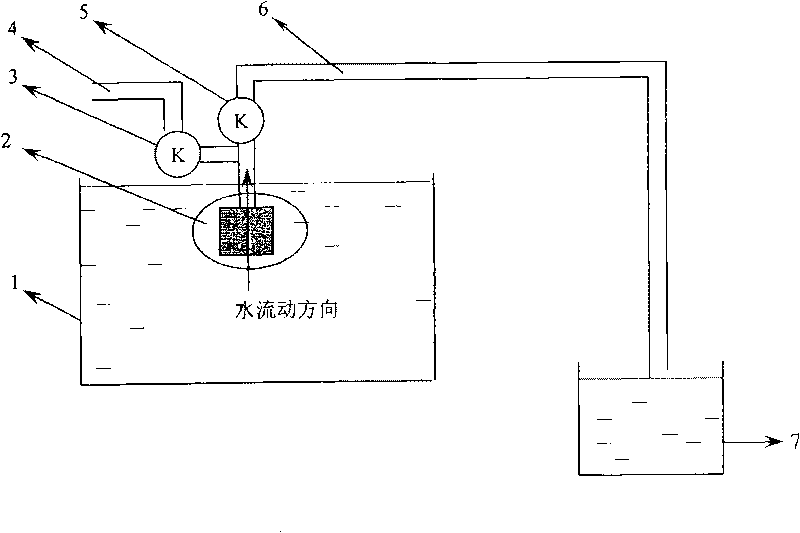

Embodiment 1

[0032] The apparent diameter of microalgae is about 5 μm, and the culture density is 0.2 g L dry weight -1 , the area of the microporous membrane is 20cm 2 , choose 5μm pore size microfiltration membrane + 2μm pore size microfiltration membrane, add absorbent cotton between the microfiltration membrane and the siphon, so that the water can gradually move upward through capillary phenomenon, the inner diameter of the siphon is 6mm, between the microalgae cultivation tank and the water collection tank The liquid level difference between them is 30cm, the water flux per hour is 182ml, and the duration is 3 hours (h). After backwashing with water, the water flux does not decrease significantly within 2h.

Embodiment 2

[0034] The apparent diameter of microalgae is about 3 μm, and the culture density is 0.7 g L dry weight -1 , the area of the microfiltration membrane is 5cm 2 , choose a microfiltration membrane with a pore size of 5 μm + a microfiltration membrane with a pore size of 1 μm, and add absorbent cotton between the microfiltration membrane and the siphon, so that the water can gradually move upward through capillary phenomena. The liquid level difference between them is 30cm, the water flux per hour is 40ml, and the duration is 2h. After backwashing with water, the water flux does not decrease significantly within 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com