High-molecular nano-fiber net structure binding material and preparation method thereof

A technology of bonding material and network structure, which is applied in the field of polymer nanofiber network structure bonding material and its preparation, and achieves the effects of good shape, enhanced electrostatic force and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

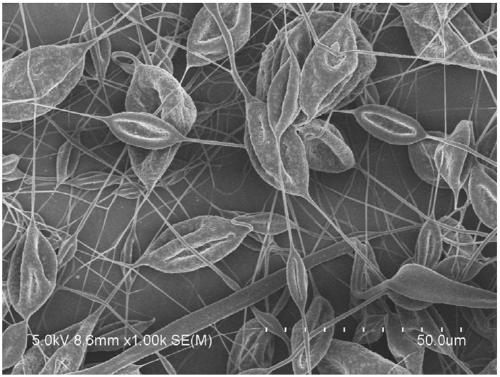

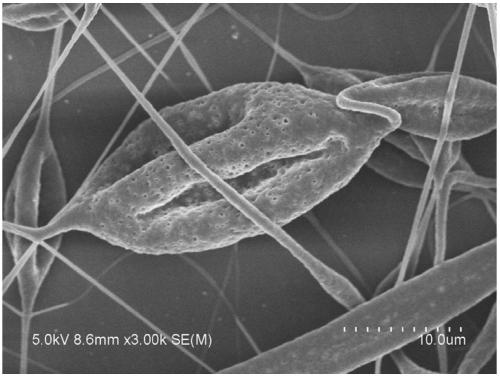

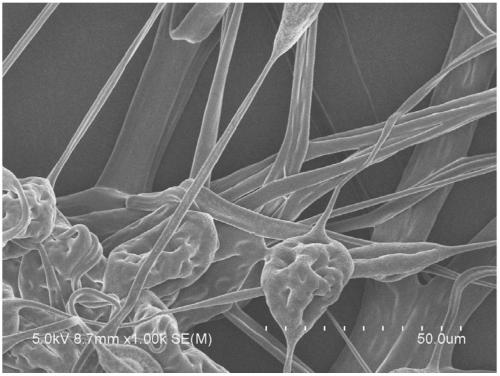

Image

Examples

Embodiment 1

[0029] A certain amount of lithium chloride nanoparticles was weighed and crushed in an agate mortar, then placed in a muffle furnace, dried at 400°C for 4 hours, taken out, and cooled to room temperature in a desiccator. Use an electronic balance to accurately weigh 1.4g of EVA resin particles, 13.02g of CHCl 3 and 5.58g THF in a conical flask of appropriate size, add the rotor, place it on a constant temperature magnetic stirrer, stir for 15min at a temperature of 40°C until the solute is completely dissolved, then add 0.04g of chlorine to the mixed solution lithium nanoparticles, thereby preparing a composite spinning solution with a mass fraction of EVA of 7%, wherein CHCl 3 The mass ratio of THF and THF is 7:3, and the mass fraction of lithium chloride is 0.2%.

[0030] Perform electrospinning on the above spinning solution, set the spinning parameters as voltage 15kV, spinning distance 15cm, flow rate 0.3mL / h, temperature 25°C, spinning time 5h, nanofibers are received ...

Embodiment 2

[0032] A certain amount of lithium chloride nanoparticles was weighed and crushed in an agate mortar, then placed in a muffle furnace, dried at 400°C for 4 hours, taken out, and cooled to room temperature in a desiccator. Use an electronic balance to accurately weigh 1.2g of EVA resin particles, 13.16g of CHCl 3 and 5.64g THF in a conical flask of appropriate size, add the rotor, place it on a constant temperature magnetic stirrer, stir for 15min at a temperature of 40°C until the solute is completely dissolved, then add 0.06g of chlorine to the mixed solution lithium nanoparticles, thereby preparing a composite spinning solution with a mass fraction of EVA of 6%, wherein CHCl 3 The mass ratio of THF and THF is 7:3, and the mass fraction of lithium chloride is 0.3%.

[0033] Perform electrospinning on the above spinning solution, set the spinning parameters as voltage 17kV, spinning distance 16cm, flow rate 0.5mL / h, temperature 30°C, spinning time 6h, nanofibers are received ...

Embodiment 3

[0035] A certain amount of lithium chloride nanoparticles was weighed and crushed in an agate mortar, then placed in a muffle furnace, dried at 400°C for 4 hours, taken out, and cooled to room temperature in a desiccator. Use an electronic balance to accurately weigh 2g of EVA resin particles, 12.60g of CHCl 3 and 5.40g THF in a conical flask of appropriate size, add the rotor, place it on a constant temperature magnetic stirrer, stir for 15min at a temperature of 40°C until the solute is completely dissolved, then add 0.04g of chlorine to the mixed solution lithium nanoparticles, thereby preparing a composite spinning solution with a mass fraction of EVA of 10%, wherein CHCl 3 The mass ratio of THF and THF is 7:3, and the mass fraction of lithium chloride is 0.2%.

[0036] Perform electrospinning on the above spinning solution, set the spinning parameters as voltage 20kV, spinning distance 18cm, flow rate 0.8mL / h, temperature 28°C, spinning time 4h, nanofibers are received o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com