Dust removal filter screen plate for waste heat recovery boiler

A waste heat recovery boiler and filter technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve problems such as blockage and failure to solve the surface of stencil plate, etc., to increase water output, facilitate boiler cinder, reduce The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

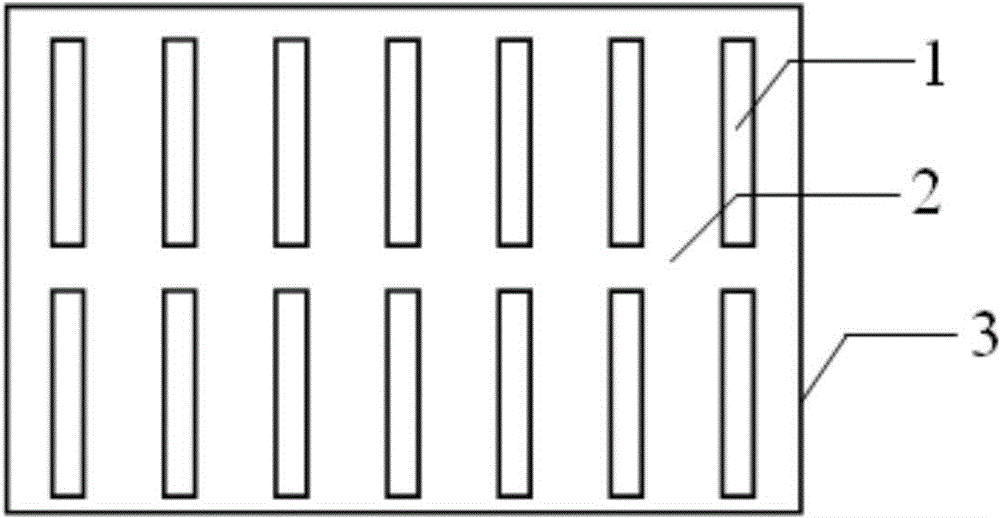

[0019] A waste heat recovery boiler dust removal filter net plate, its structure is as follows figure 1 As shown, it includes a stencil outer frame 3 and a stencil body 2 arranged in the stencil outer frame 3 , and the stencil body 2 is uniformly provided with elongated holes 1 . The strip-shaped holes 1 are distributed in rows, and the positions of the strip-shaped holes 1 between two adjacent rows are consistent. In this embodiment, the length of the elongated holes 1 is 3 times the distance between two adjacent elongated holes 1 in each row, and the width is 1 / 3 of the distance between two adjacent elongated holes 1 in each row. The inner surface of the elongated hole 1 is inclined, the angle between the inner surface and the horizontal direction is 30°, and the cross-sectional area of the elongated hole gradually decreases from the front to the back of the screen body.

Embodiment 2

[0021] The utility model relates to a dust removal filter net plate for a waste heat recovery boiler, which comprises a net plate outer frame and a net plate body arranged in the net plate outer frame, and strip-shaped holes are evenly opened on the net plate body. The strip-shaped holes are distributed in rows, and the positions of the strip-shaped holes between two adjacent rows are staggered with each other. The length of the elongated holes is twice the distance between two adjacent elongated holes in each row, and the width is 1 / 2 of the distance between two adjacent elongated holes in each row. The inner surface of the elongated hole is inclined, the angle between the inner surface and the horizontal direction is 45°, and the cross-sectional area of the elongated hole gradually decreases from the front to the back of the screen body.

[0022] After passing through the three slag pool filter screens, the remaining cinders are mostly irregular particles, which are easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com