Humidity control for long term storage of articles

a technology for long-term storage and humidity control, applied in the direction of packaging, gas/liquid distribution and storage, container preventing decay, etc., can solve the problems of unfavorable long-term storage, unpleasant mustiness, mold growth, etc., and achieve the effect of maintaining the textural qualities of foods, low permeability, and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

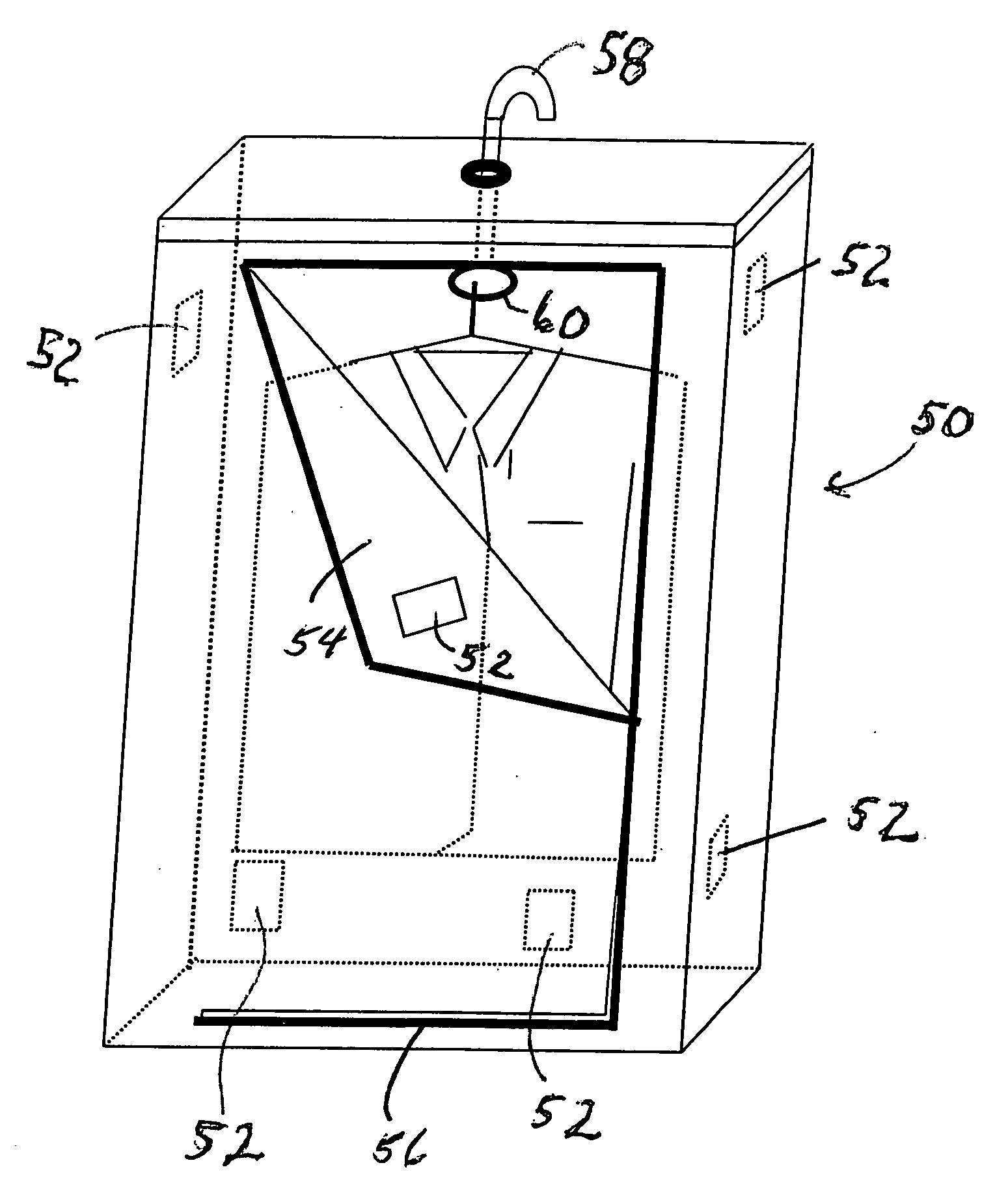

Image

Examples

example 1

[0043]Rectangular bags having relatively long and short edges were prepared from clear, 6-mil vinyl. The bags were heat sealed on 3 edges and provided with a slider-seal at the fourth, a narrow or short edge to provide access to produce a storage container.

[0044]Filling for units designed to regulate at about 32% RH was prepared as follows:

Water (45° C.)300 gXanthan gum 14 g

were mixed in a blender to disperse the gum for quick hydration.

Magnesium Chloride hexahydrate1000 gwas added with stirring.Then Calcium chloride dihydrate 450 g

was added and mixed thoroughly to form a paste of which approximately 70 g each was placed in 3.5×5.25 inch pouches (units) prepared from 1.5 mil polyester elastomer film extruded on paper.

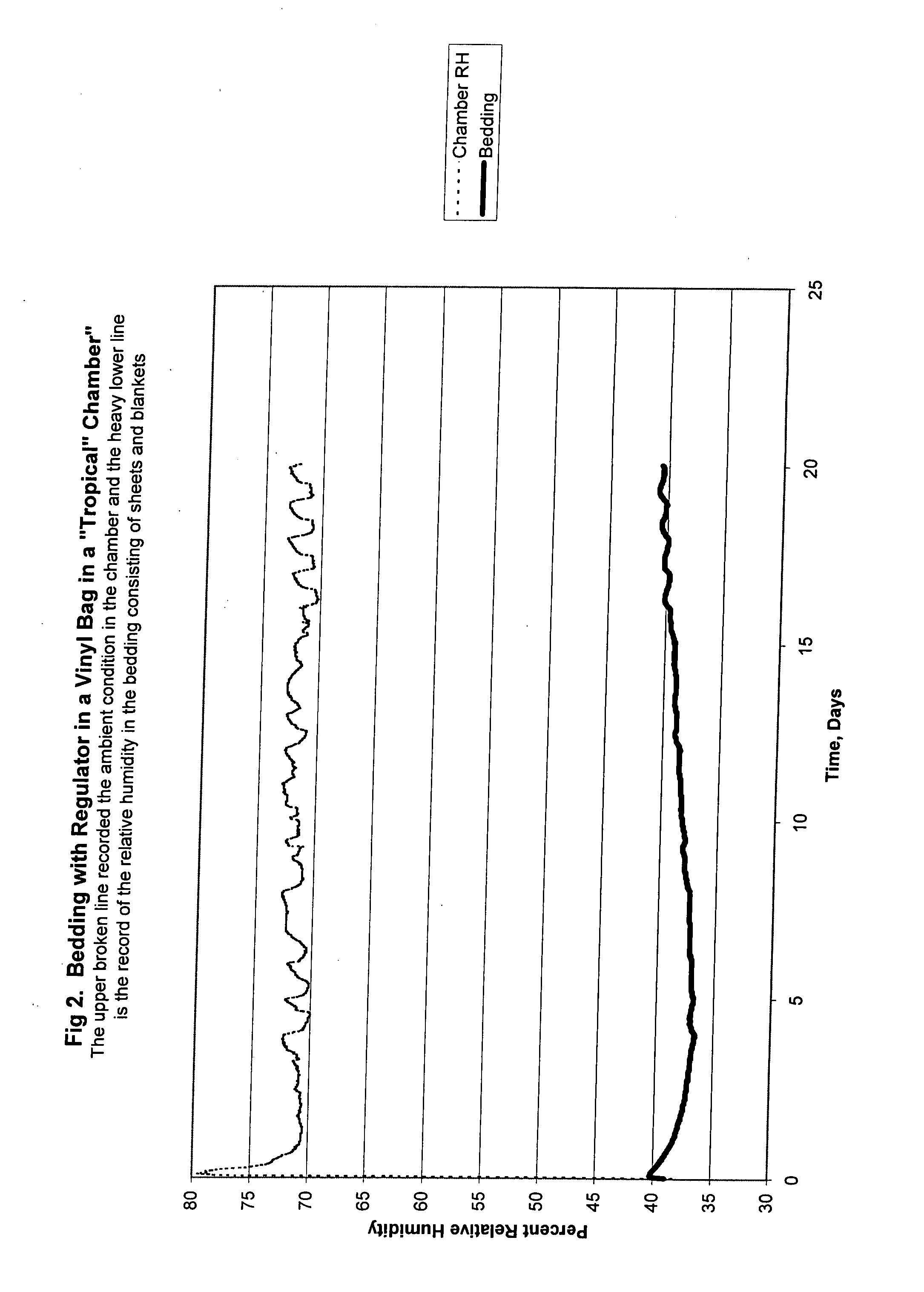

[0045]Approximately 2.13 kg of bedding consisting of sheets, pillow cases and a heavy knit blanket was placed in one of the vinyl bags. Eight pouches were weighed and distributed one to two layers of fabric around the perimeter of the fabric in the vinyl bag storage con...

example 2

[0047]Similarly, another vinyl bag from Example 1 was filled with 2.12 kg of clothing including a sport jacket, cotton shirts and slacks and a robe. Eight weighed humidity regulating units were placed in pockets of the sports coat, slacks and shirts. A data logger was placed in the inner vest pocket of the sports coat. As with the bedding, the clothes bag was placed in the high humidity chamber.

[0048]Results: The data loggers provided the data depicted by FIG. 3.

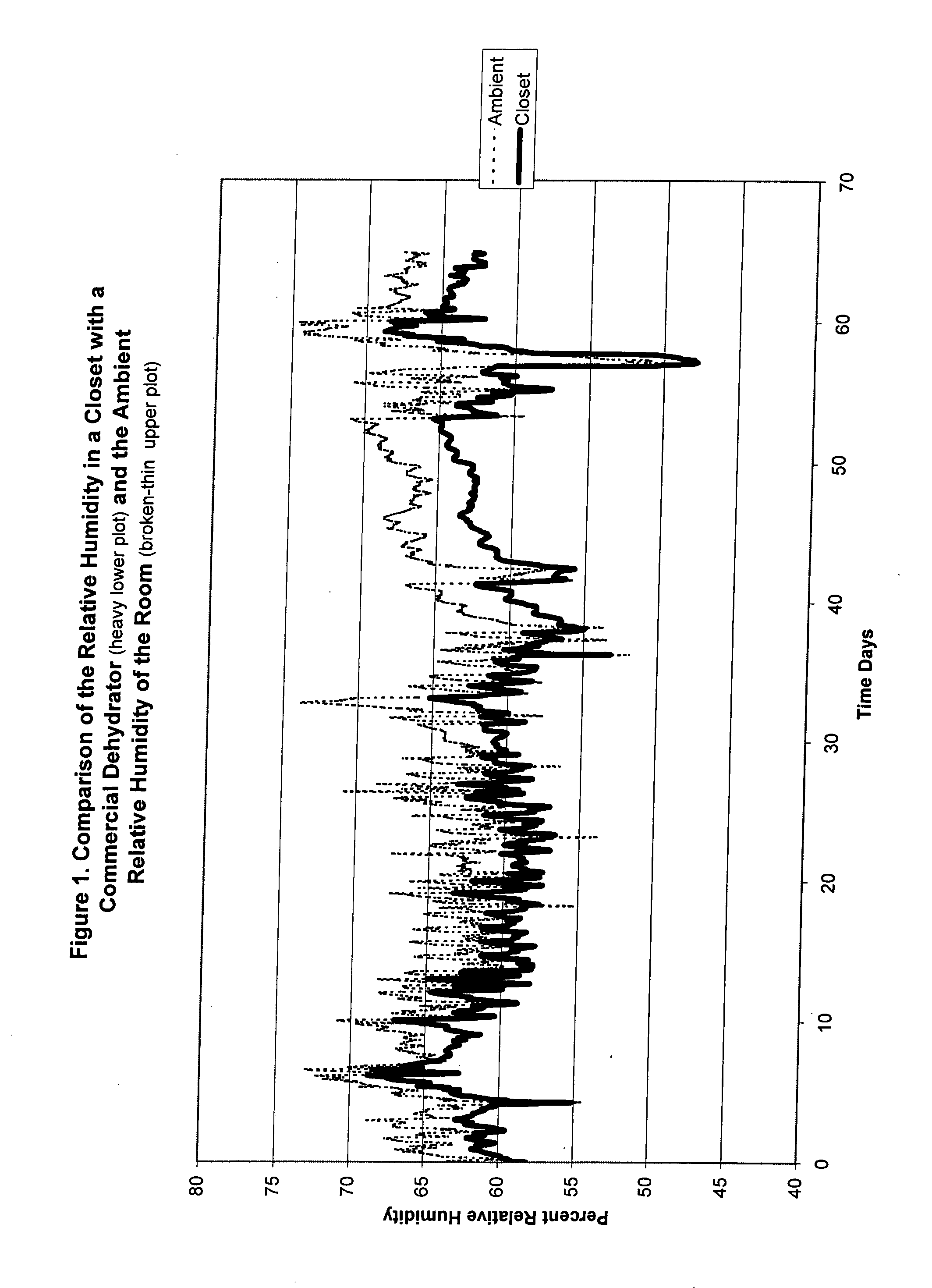

[0049]The statistical analysis of these data show very good control of the humidity within the container of clothing and good control with bedding placed in a “tropical” chamber maintained with, saturated Potassium Chloride solution. The difference in performance can be attributed to a higher water content in the bedding at the beginning of the trial in FIG. 2.

example 3

[0050]Additional units were prepared as described in Example 1.

[0051]About 2.1 Kg of bedding including cotton sheets, pillow cases, pajamas and a wool / nylon knitted blanket were placed in a 6 mil vinyl bag. A data logger was placed among the pillow cases approximately at the center of the bag and 8 humidity regulators were distributed at two levels, about ¼ of the way from the bottom and top around the perimeter of the storage bag.

[0052]This bag was placed in a “Tropical Chamber” humidified with saturated potassium chloride solution.

[0053]Results:

[0054]The clothes were held in the range of 35 to 43% relative humidity.

[0055]The moisture pick up by the pouches averaged 1.5 to 1.6 g / day hence would require about 2 units per month of storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com