Fruit and vegetable cleaning machine

A technology of fruit and vegetable cleaning machine and cleaning basket, which is applied in household appliances, applications, kitchen utensils, etc. It can solve the problems of poor removal effect of heavy metals in ozone and pungent odor, etc., to improve the cleaning effect, improve the cleaning effect, avoid breeding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

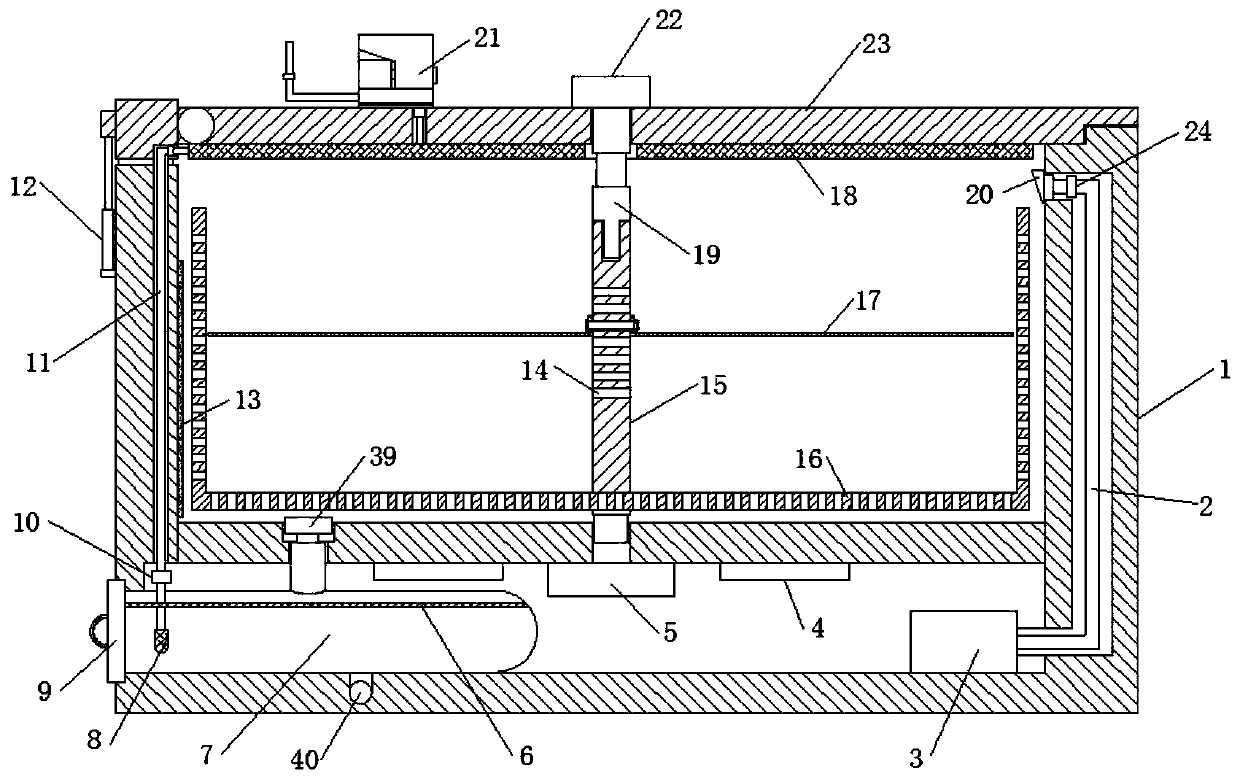

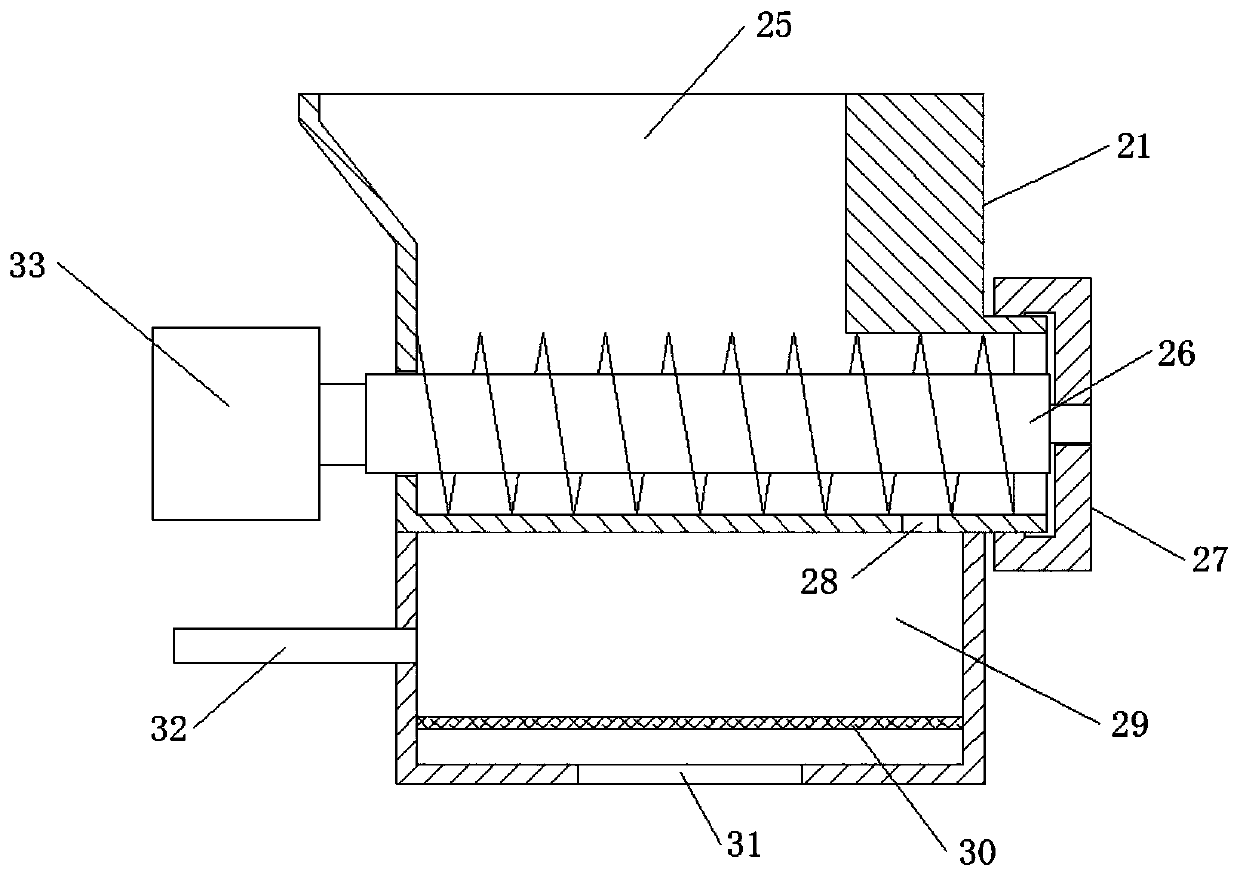

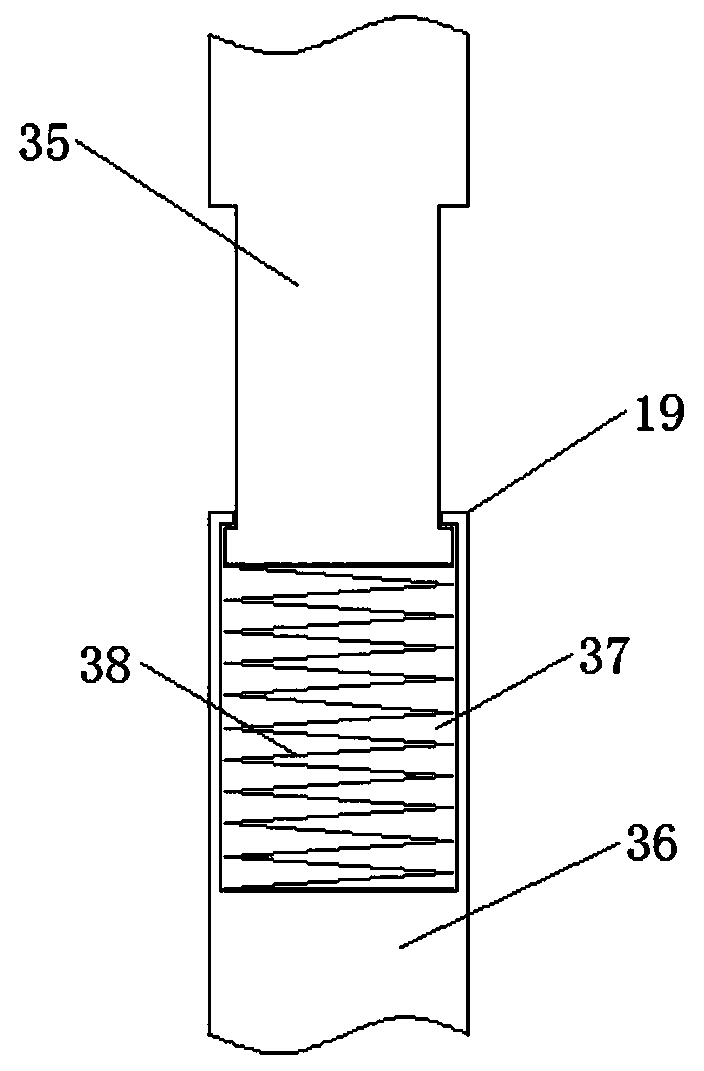

[0035] The base at the lower end of the housing 1 is also provided with a motor A5 that can move the cleaning basket 16 up and down, and the rotating shaft 19 includes a fixed part 35 and a sliding part 36, and one end of the sliding part 36 that is in contact with the fixed part 35 A cavity 37 is provided, the end of the fixing part 35 away from the motor B22 is located in the cavity 37 of the sliding part 36, and a spring 38 is arranged between the bottom of the cavity 37 and the top of the fixing part 35; The housing 1 is provided with an electric push rod 12 on the outside near the hinge joint between the cover plate 23 and the housing 1, one end of the electric push rod 12 is fixedly connected to the outer side wall of the housing 1, and the other end of the electric push rod 12 is One side is fixedly connected to the outer wall of the cover plate 23 , and the return pipe 11 located in the inner wall of the housing 1 is expandable.

Embodiment 2

[0037] refer to Image 6 , is another embodiment of the present application, a motor A5 is provided in the base of the lower end of the housing 1, the output end of the motor A5 is connected to the cleaning basket 16 through a rotating shaft, and the base of the lower end of the housing 1 is also Ozone generator 3 is provided, and the output end of described ozone generator 3 is provided with supersonic pump 43, and an output end of described supersonic pump 43 is fixedly connected with ozone conveying pipe 2, and described ozone conveying pipe 2 is away from supersonic sound. One end of the pump 43 runs through the side wall of the housing 1 and communicates with the chamber of the housing 1, and the end of the ozone delivery pipe 2 communicating with the chamber of the housing 1 is provided with an ozone outlet nozzle 20, The ozone outlet nozzle 20 is detachably fixed on the inner wall of the chamber of the housing 1, and the end of the ozone delivery pipe 2 near the ozone o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com