Powder fracturing fluid continuous blending method

A process method and fracturing fluid technology, applied in mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of low production efficiency, high production cost, low degree of automation, etc., and achieve easy operation, uniformity improvement, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

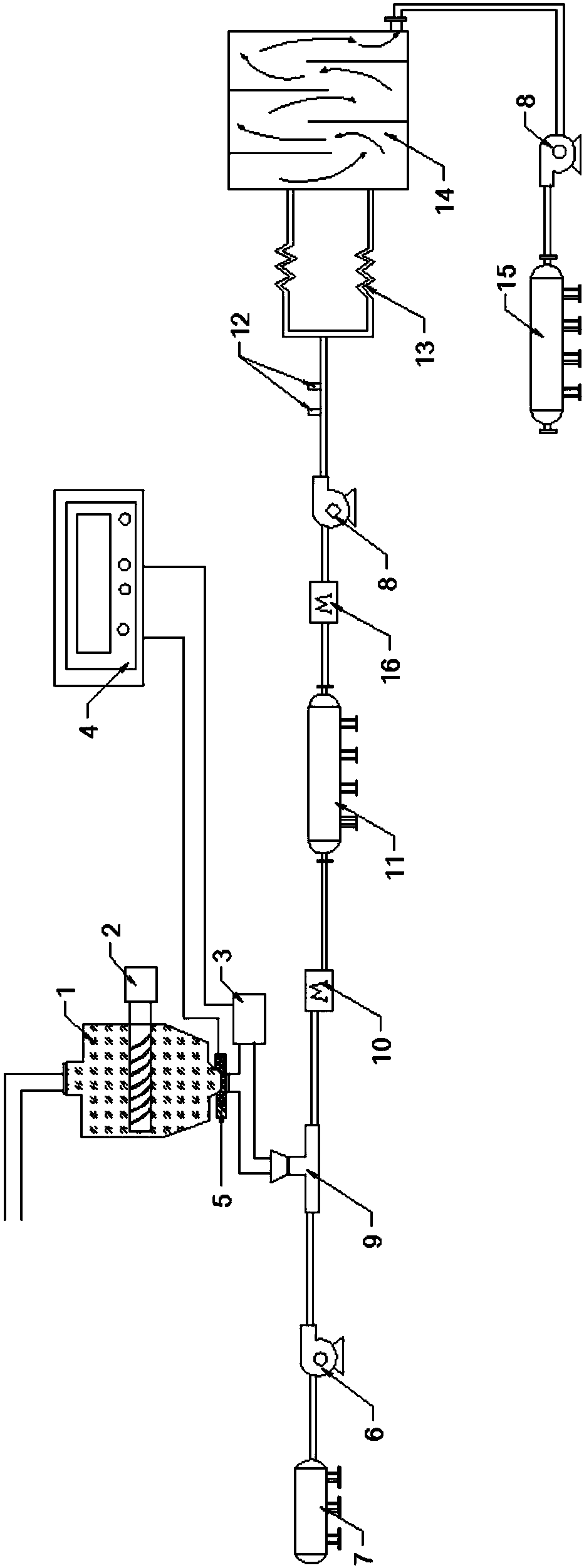

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0024] Such as figure 1 As shown, a powder fracturing fluid continuous mixing process, wherein the devices involved mainly include a hopper 1, a weight loss compensation sensor 5, a screw feeder 3, a first water inlet manifold 7, a first centrifugal pump 6, Ejector 9 , second water inlet manifold 11 , second centrifugal pump 8 , mixing system, and water outlet manifold 15 . Wherein, due to technological requirements, the first centrifugal pump 6 and the second centrifugal pump 8 are centrifugal pumps of different models.

[0025] The method mainly includes the following steps: first, the powder used for preparing fracturing fluid is transported into the hopper 1, and a screw powder relaxer 2 is installed in the hopper 1 to keep the powder in a loose state for feeding, and then The weight loss c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com