Container type refrigeration station

A container-type, freezing station technology, applied in household refrigeration devices, cooling fluid circulation devices, water/sludge/sewage treatment, etc., can solve the problems of low integration, high cost and inflexibility, and achieve stable internal pressure, clear water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

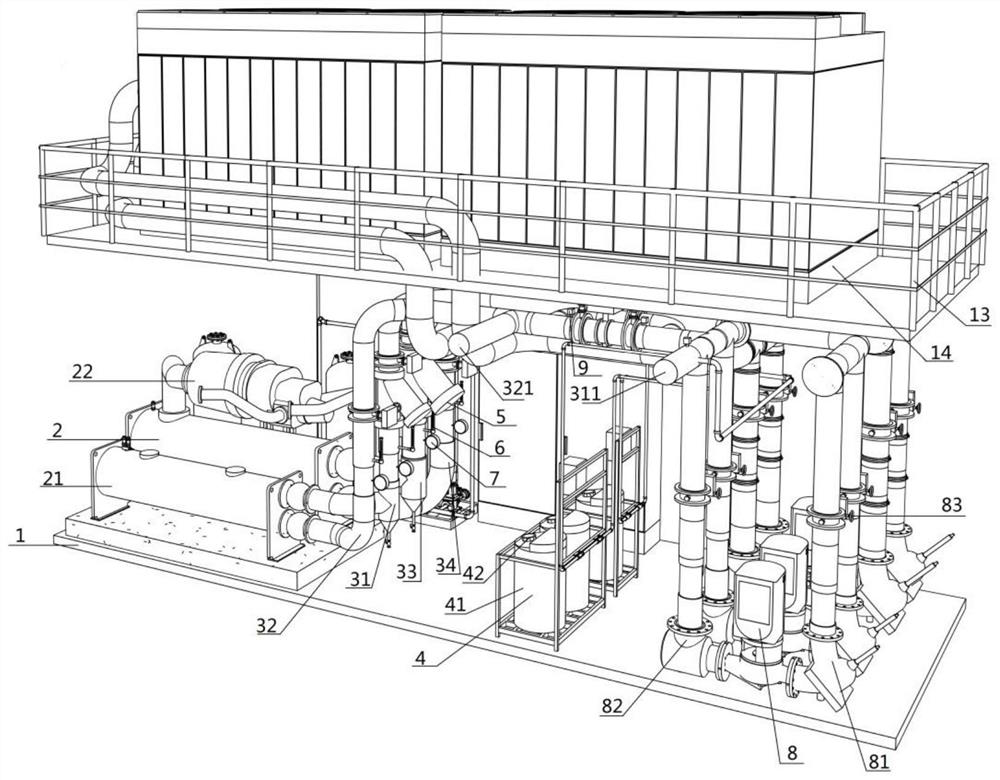

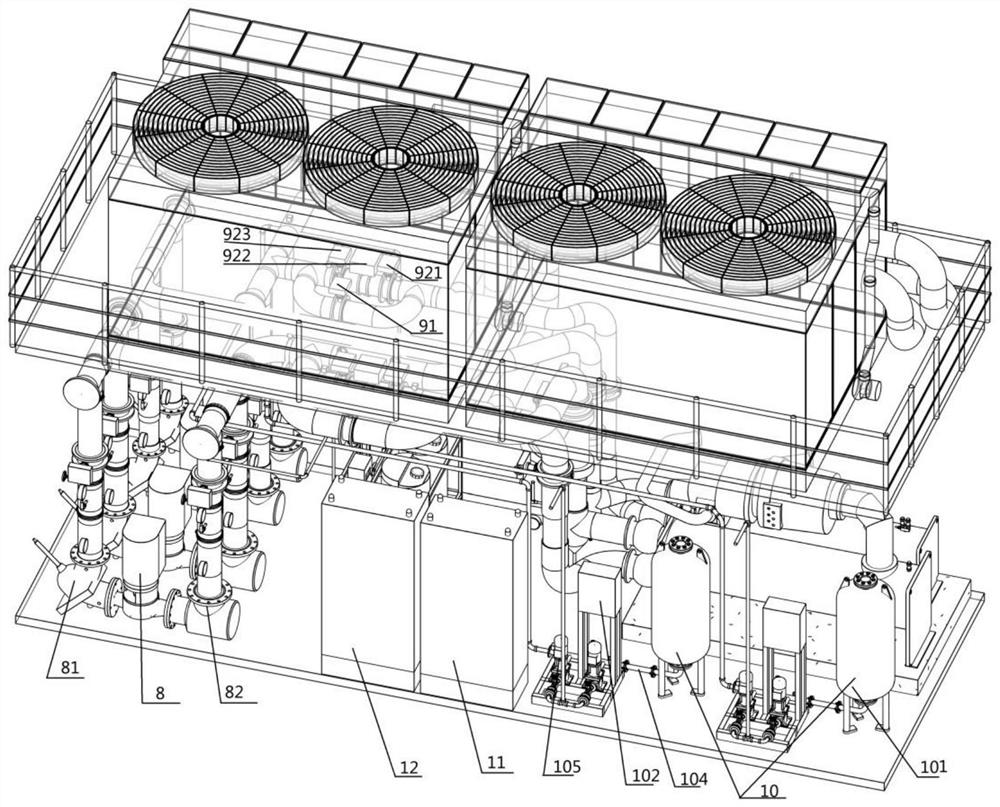

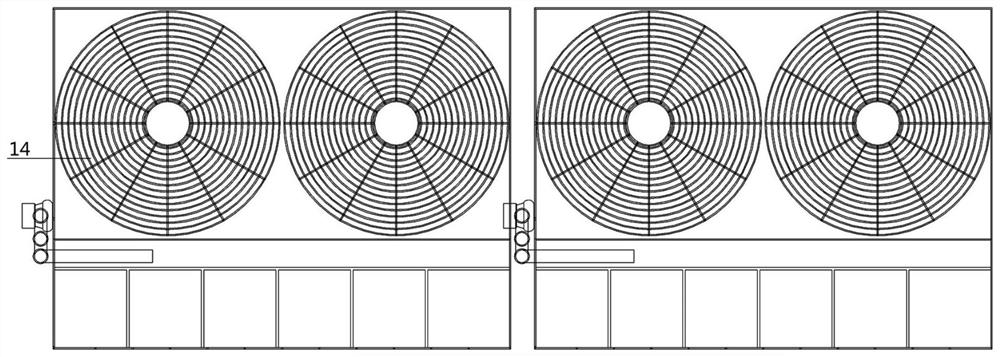

[0026] like figure 1 Shown is the structural representation of the container type freezing station of the present invention; figure 2 Shown is the structural representation of the container type freezing station of the present invention; image 3 Shown is the structural representation of closed cooling tower 14 of the present invention; Figure 4 Shown is the structural representation of the container type freezing station of the present invention; Figure 5 As shown, it is a schematic diagram of the waterway structure of the container type freezing station of the present invention; Image 6 Shown is a schematic structural view of the vertical pipeline pump 8 of the present invention.

[0027]A container-type refrigeration station, including a container body 1, a refrigeration unit 2, several water pipes 3, an automatic dosing device 4, a Y-shaped filter 5, a vertical pipeline pump 8, a constant pressure water supply device 10, and a main power supply 11 for the equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com