Advanced treatment composite catalyst for industrial wastewater as well as preparation method and application thereof

A composite catalyst, advanced treatment technology, applied in physical/chemical process catalysts, oxidized water/sewage treatment, chemical instruments and methods, etc. The effect of improved oxidation capacity, improved COD removal rate, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

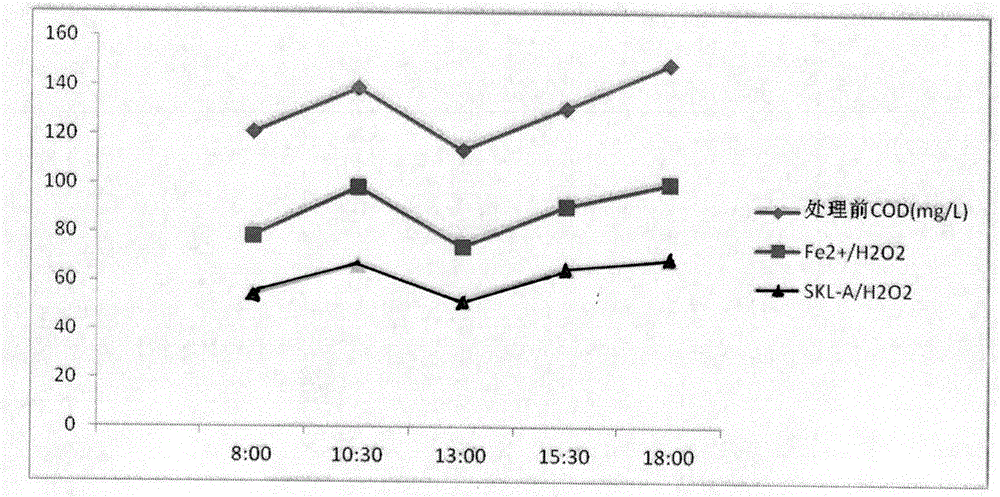

Image

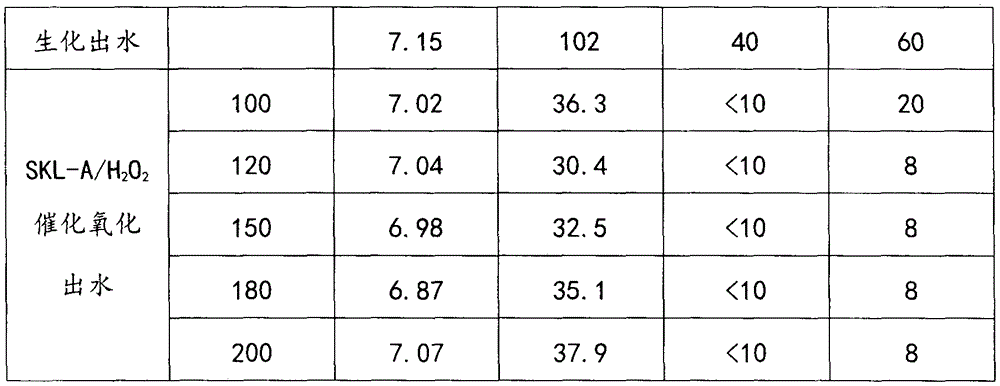

Examples

Embodiment 1

[0028] H at room temperature 3 PW 12 o 40 ·nH 2 O dissolves in H 2 In O, use NaOH to adjust the pH to 4.5-5.0, add KCl, evaporate the solution at 80°C with a rotary evaporator and halve it, refrigerate at 4°C overnight to obtain a white solid, and recrystallize once with water to obtain PW 11 . Weigh molar ratio Fe 2 (SO 4 ) 3 : CuSO 4 ·5H 2 O: MnSO4 ·H 2 O: CoSO 4 ·7H 2 O: NiSO 4 ·6H 2 O=10:5:0.5~0.3:0.03~0.02:0.01 Put in a round bottom flask, add water and stir continuously to dissolve it, heat the solution to 80°C, adjust the pH to 4, add 10 times of PW by weight 11 Reaction 2h. The obtained solid was recrystallized to obtain the parent PW 11 M.

Embodiment 2

[0030] Ethyl orthosilicate: n-butanol: H 2 O was mixed uniformly according to the volume ratio of 3:1:2, and nitric acid was added to adjust the pH to 1, stirred for 1 h, then heated to 45°C and stirred for 3 h, then heated to 80°C and continued to stir until a hydrosol was formed. The resulting hydrosol was dehydrated under vacuum at 45°C for 12h, then calcined for 6h to obtain a dry sol, washed three times with hot water, calcined at 80°C for 6h, and then calcined at 150°C for 6h to obtain a white powder SiO 2 Carrier; white powdered SiO 2 Disperse the carrier in toluene, add APS and mix evenly, SiO 2 :APS at a weight ratio of 2:1, the mixture was refluxed and stirred for 12 hours, and centrifuged to obtain an amine-modified carrier.

Embodiment 3

[0032] The above-prepared APS-SiO 2 with PW 11 M (M=Fe, Cu doped with Mn, Co, Ni) was mixed uniformly at a weight ratio of 2:1, the pH of the solution was controlled to 6-7, stirred for 24 hours, centrifuged, washed several times with distilled water and dried to obtain the composite catalyst SKL-A (PW 11 (M)-APS-SiO 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com