Landfill leachate treatment method

A technology for landfill leachate and a treatment method, which is applied in the field of landfill leachate treatment, can solve the problems of increasing the difficulty of landfill leachate treatment, high conductivity of landfill leachate, and large area of treatment facilities, so as to improve the biochemical efficiency of landfill leachate. properties and stability, improving the effect of biochemical treatment, and promoting the effect of degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

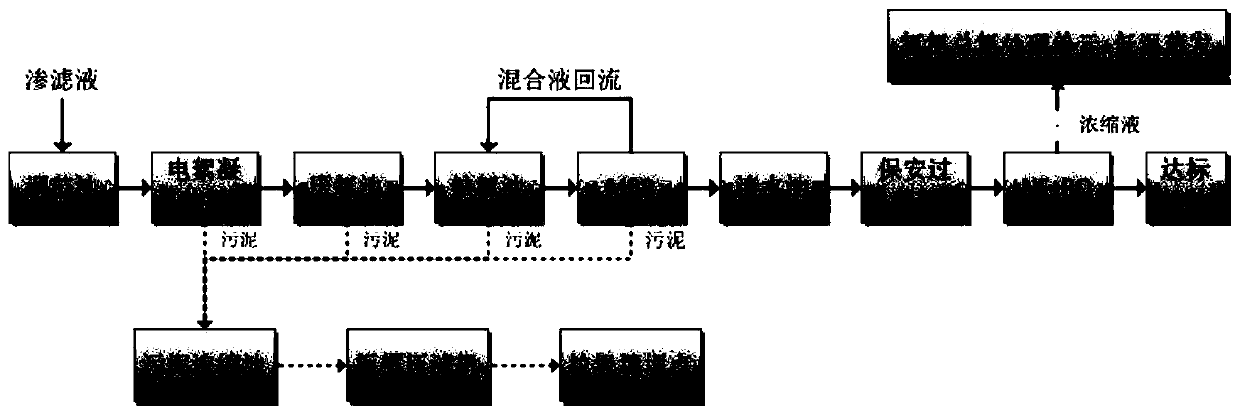

[0035] A treatment method for landfill leachate, such as figure 1 As shown, it includes the following steps:

[0036] Step 1. Regulating pool treatment: Landfill leachate enters the regulating pool to regulate water volume and water quality; among them, the interior of the regulating pool is equipped with a mechanical stirring device, which makes the water surface form a hydraulic jump and entrains air to decompose macromolecules While preventing organic pollutants from settling suspended particles, the effluent enters the electrocoagulation air flotation device;

[0037] Step 2. Electrocoagulation treatment: After being regulated by the regulating tank, the treatment liquid enters the electrocoagulation air flotation device quantitatively through the lift pump, and removes COD, TDS and ammonia nitrogen pollutants through electrolytic oxidation and adsorption; among them, the electrocoagulation air flotation device includes Reaction device, the reaction device is fixed with a...

Embodiment 2

[0047] A treatment method for landfill leachate, such as figure 1 As shown, it includes the following steps:

[0048] Step 1. Regulating pool treatment: Landfill leachate enters the regulating pool to regulate water volume and water quality; among them, the interior of the regulating pool is equipped with a mechanical stirring device, which makes the water surface form a hydraulic jump and entrains air to decompose macromolecules While preventing organic pollutants from settling suspended particles, the effluent enters the electrocoagulation air flotation device;

[0049] Step 2. Electrocoagulation treatment: After being regulated by the regulating tank, the treatment liquid enters the electrocoagulation air flotation device quantitatively through the lift pump, and removes COD, TDS and ammonia nitrogen pollutants through electrolytic oxidation and adsorption; among them, the electrocoagulation air flotation device includes Reaction device, the reaction device is fixed with a...

Embodiment 3

[0059] A treatment method for landfill leachate, such as figure 1 As shown, it includes the following steps:

[0060] Step 1. Regulating pool treatment: Landfill leachate enters the regulating pool to regulate water volume and water quality; among them, the interior of the regulating pool is equipped with a mechanical stirring device, which makes the water surface form a hydraulic jump and entrains air to decompose macromolecules While preventing organic pollutants from settling suspended particles, the effluent enters the electrocoagulation air flotation device;

[0061] Step 2. Electrocoagulation treatment: After being regulated by the regulating tank, the treatment liquid enters the electrocoagulation air flotation device quantitatively through the lift pump, and removes COD, TDS and ammonia nitrogen pollutants through electrolytic oxidation and adsorption; among them, the electrocoagulation air flotation device includes Reaction device, the reaction device is fixed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com