Garbage gasification boiler and application method thereof

A gasification boiler and gasification furnace technology, applied in the direction of incinerators, combustion methods, climate sustainability, etc., can solve the problems of low energy utilization rate, secondary pollution, inconvenient maintenance and use, etc., to improve energy utilization efficiency, ensure internal pressure, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

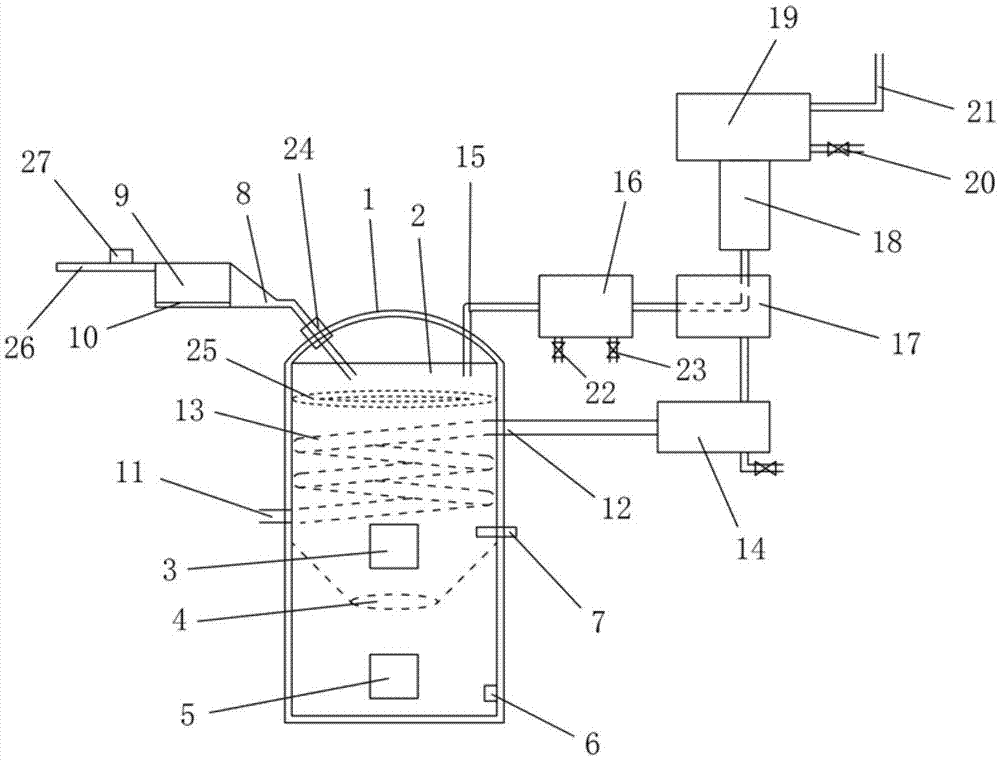

[0048] like figure 1 As shown, an embodiment of the waste gasification boiler of the present invention includes a waste gasification device and a gas processing device. Among them, the refuse gasification device includes a gasification furnace body 1 and a furnace chamber 2 provided in the gasification furnace body 1 . The upper part of the furnace chamber 2 is provided with a steam collecting pipe 25, and a small amount of water vapor is generated by the steam collecting pipe 25 to supply the water vapor required for the gasification of the garbage in the furnace chamber 2. The lower part of the furnace chamber 2 is provided with a lower ash port 4, a gasification medium input port 6 is provided below the lower ash port 4, and an igniter 7 is provided above. The upper part of the gasification furnace body 1 is also provided with a gas gas collecting pipe 15 . The gas treatment device of the waste gasification boiler includes an oil-water separator 16 , a gas waste heat reco...

Embodiment 2

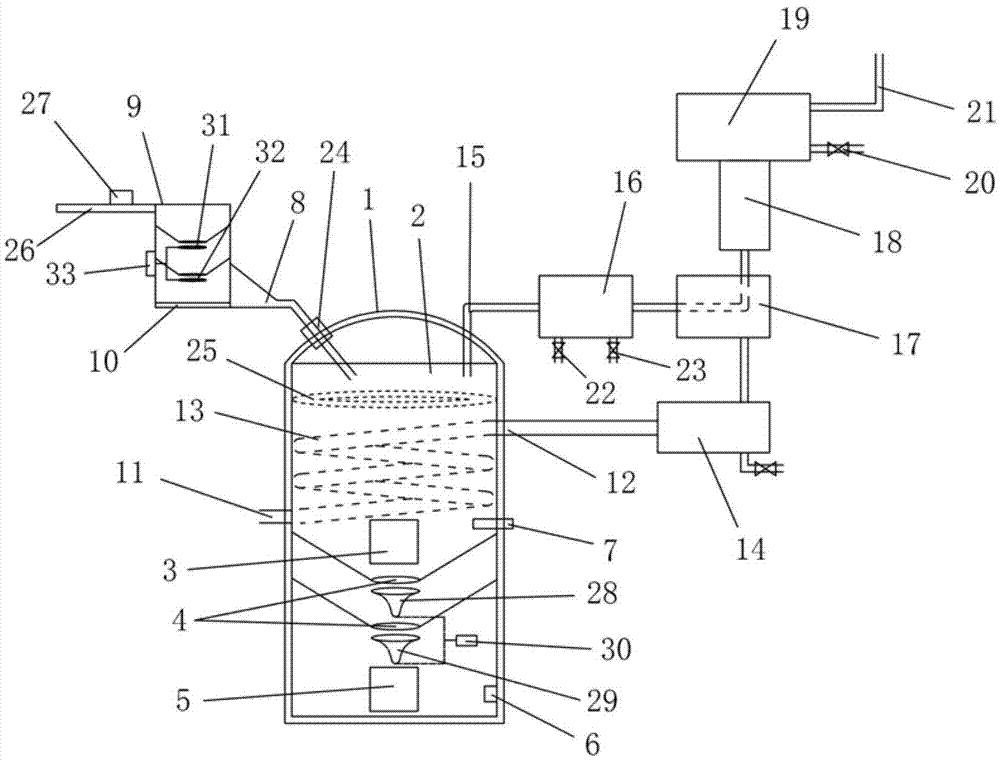

[0055] like figure 2 As shown, an embodiment of the waste gasification boiler of the present invention includes a gasification furnace body 1 and a furnace chamber 2 arranged in the gasification furnace body 1 . A gas gas collecting pipe 15 is arranged on the upper side wall of the gasification furnace body 1, and the gas gas collecting pipe 15 is connected to a gas processing device, and the gas processing device includes an oil-water separator 16, a gas waste heat recovery device 17, and a spraying device connected in sequence. Dust suppression device 18 and air purification processor 19. Among them, the oil-water separator 16 is connected to the gas collecting pipe 15, the air purification processor 19 is provided with a gas outlet 20 and a smoke exhaust pipe 21, the smoke exhaust pipe 21 is a PVC plastic pipe, and the bottom of the oil-water separator 16 is provided with a water outlet 22 and a smoke exhaust pipe 21. Drain port 23. The lower part of the furnace chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com