Boot shape maintaining body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

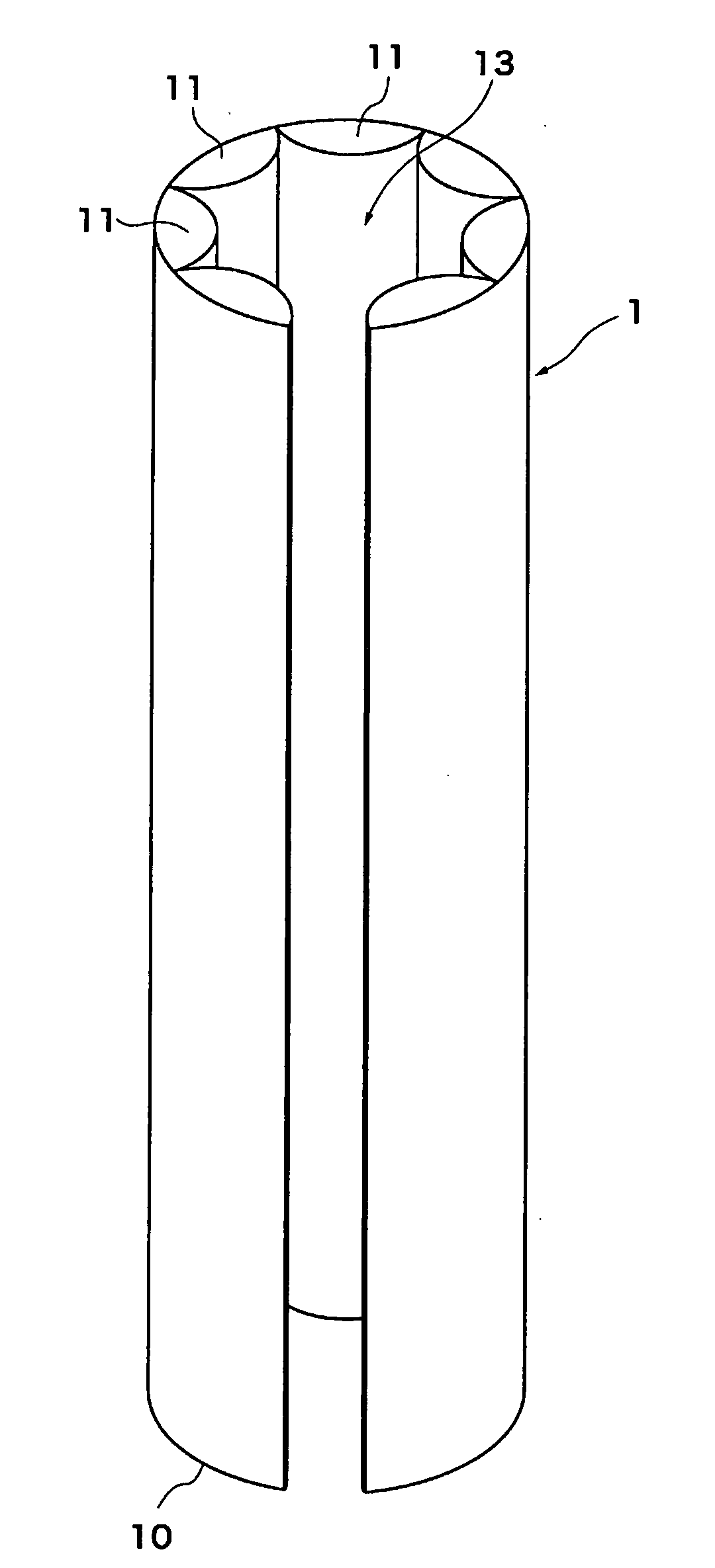

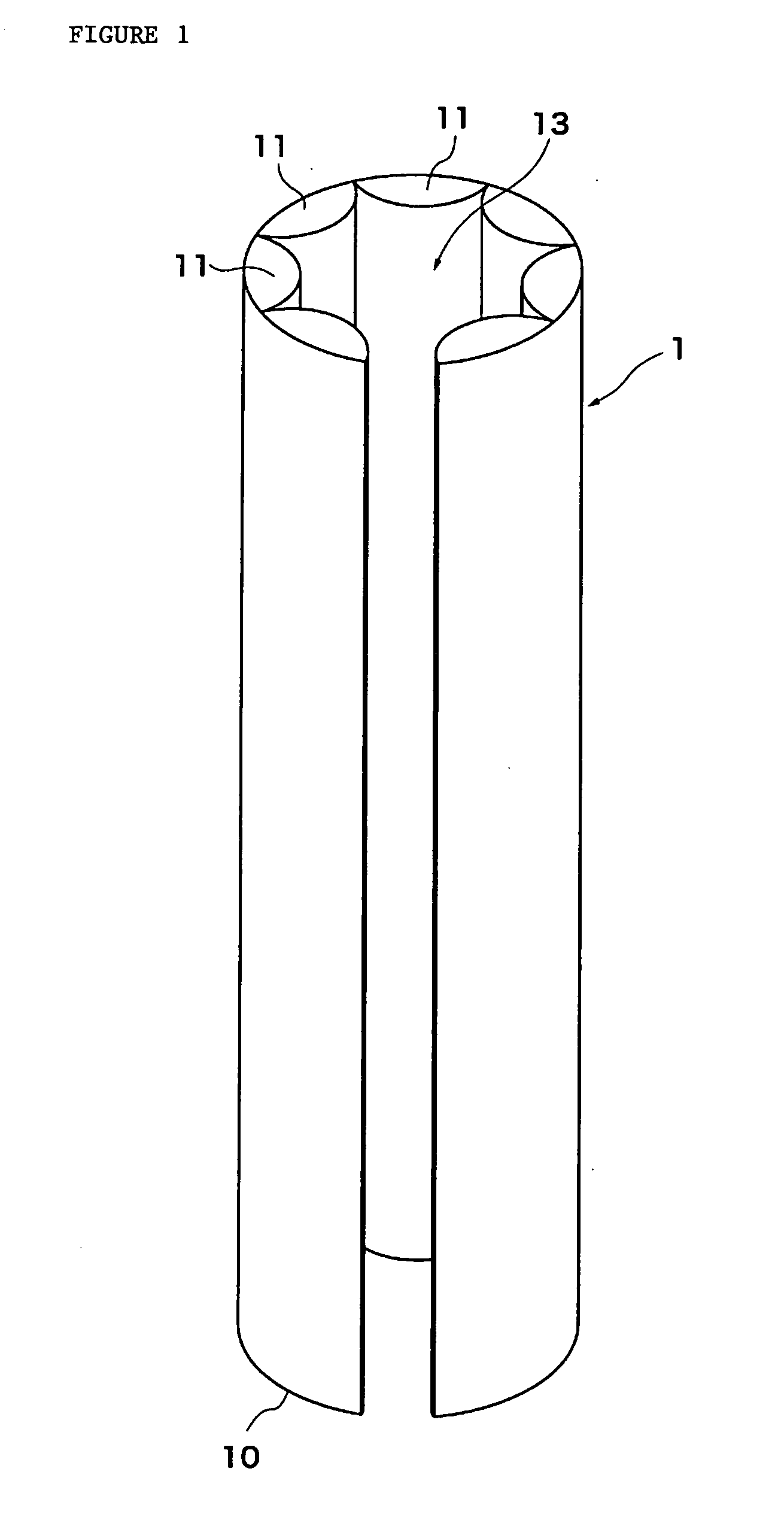

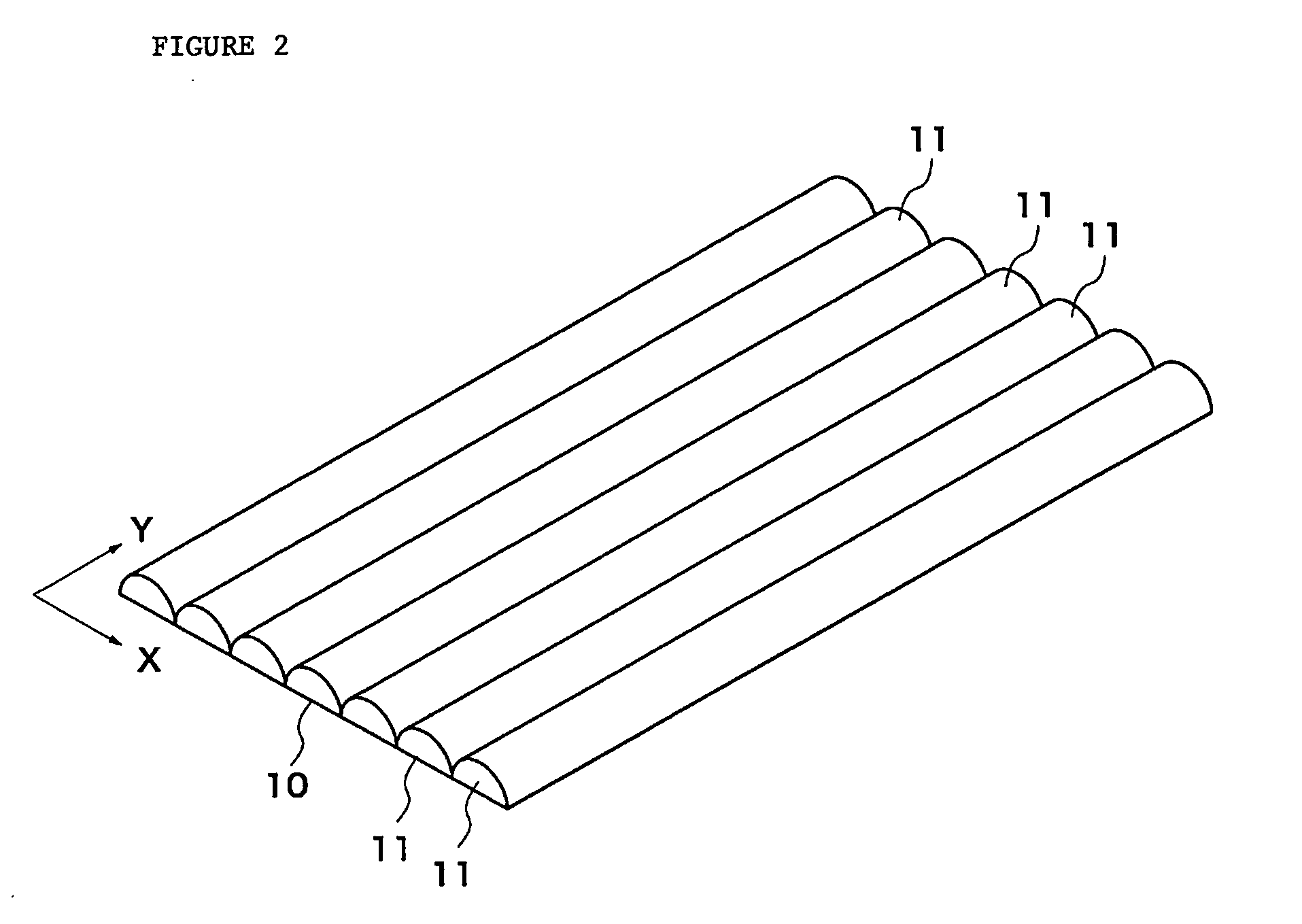

[0023]FIG. 1 shows a perspective view of a boot shape keeper 1 according to a first embodiment to which the invention is applied. This boot shape keeper 1 is formed mainly by rolling a plastic sheet 10 into a coupled cylindrical shape.

[0024]The plastic sheet 10 is a thermoplastic resin sheet, such as non-permeable polyethylene. The thermoplastic resin may be adequately selected from polypropylene, polyethylene terephthalate, nylon, vinyl chloride, polycarbonate, etc. in addition to polyethylene.

[0025]The plastic sheet 10 has strip air chambers 11 elongated in an up-down direction y and arranged in columns in a widthwise direction x as shown in FIG. 2. A gas is sealed in the air chambers 11 beforehand. The air chambers 11 are formed by placing two rectangular sheets constituting the plastic sheet 10 one on the other and press-bonding the rectangular sheets in the up-down direction, which is not restrictive, and may be realized by any well-known method. In the example of FIG. 2, the a...

second embodiment

[0035]FIG. 5A shows a perspective view of a boot shape keeper 3 according to a second embodiment to which the invention is applied. This boot shape keeper 3 has a body part 30 formed by rolling a plastic sheet with a gas enclosed therein beforehand into a cylindrical shape, and at least one projecting part 32 projecting downward from the lower end of the body part 30. A through hole 31 is formed in the cylindrically formed body part 30. Although the following description will be given of a case where two projecting parts 32 are formed, which is not restrictive, the projecting parts 32 may be formed in any quantity, any volume and any shape.

[0036]The plastic sheet is a thermoplastic resin sheet, such as non-permeable polyethylene. The thermoplastic resin may be adequately selected from polypropylene, polyethylene terephthalate, nylon, vinyl chloride, polycarbonate, etc. in addition to polyethylene.

[0037]The body part 30 can maintain the fixed shape with the air enclosed therein. The ...

third embodiment

[0048]FIGS. 8A and 8B show perspective views of a boot shape keeper 4 according to a third embodiment to which the invention is applied. This boot shape keeper 4 has a body part 40 formed by rolling a plastic sheet with a gas enclosed therein beforehand into a cylindrical shape, and a through hole 42b provided in the lower portion of the side wall of the body part 40, or a groove portion 42a formed in the lower end of the side wall of the body part 40. The groove portion 42a and through hole 42b may have any shape or may be formed in any quantity. The through hole 42b is connected to the through hole 41 in the cylindrical body part 40. Although the location at which the through hole 42b is formed is adjusted beforehand in connection with at least the position of the insole part 23 of the boot 2, it is desirable that the through hole 42b should be formed at any position at least at the lower half. The body part 40 can maintain the fixed shape with the air enclosed therein.

[0049]At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com