Preparation method and application of a polymer vesicle with sugar sponge function

A technology of polymers and vesicles, applied in the fields of filters in blood vessels, medical science, surgery, etc., can solve the problems of difficulty, limited application prospects, limited research on sugar-responsive assemblies, etc., and achieve the effect of good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]

[0041] The preparation method of sugar-responsive polymer vesicles of the present invention includes the following steps:

[0042] (1) Synthesis steps of amphiphilic sugar-containing polymer:

[0043] a. With brominated polyoxyethylene (PEO-Br) as the macroinitiator, the diethylaminoethyl methacrylate monomer (DEA), coumarin monomer (CMA), glucose monomer (AcGlcEMA) , The catalyst and the catalyst ligand are added to the round bottom flask, and then an appropriate amount of the first type solvent is added, mixed and removed the oxygen in the reaction system, and then reacted at 70~150℃ for 10~60h, and the polymer solution is obtained after the reaction is completed ;

[0044] b. The obtained polymer solution is subjected to rotary steaming, dissolution, passing through a neutral alumina column, re-dissolving, dialysis and freeze-drying to obtain polymer powder;

[0045] c. Dissolve the obtained polymer powder in a mixed solution of chloroform and methanol, add a strong base ...

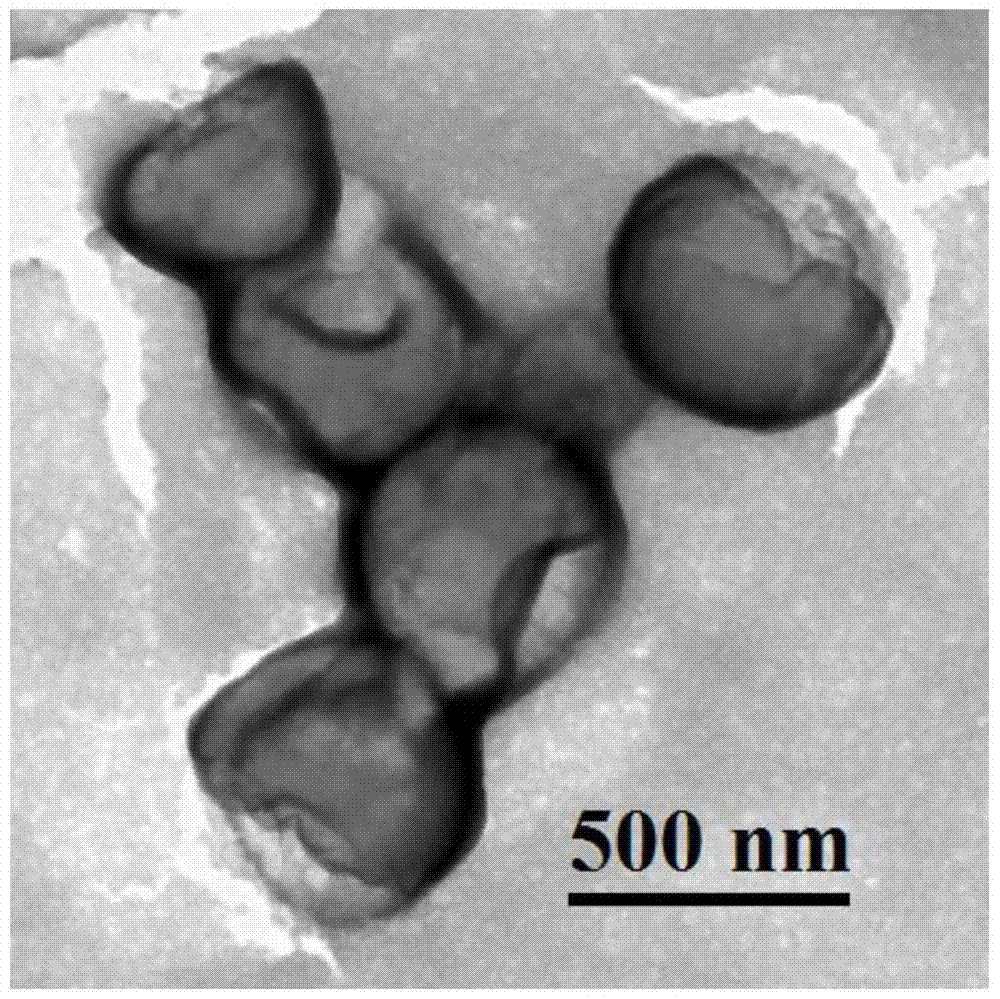

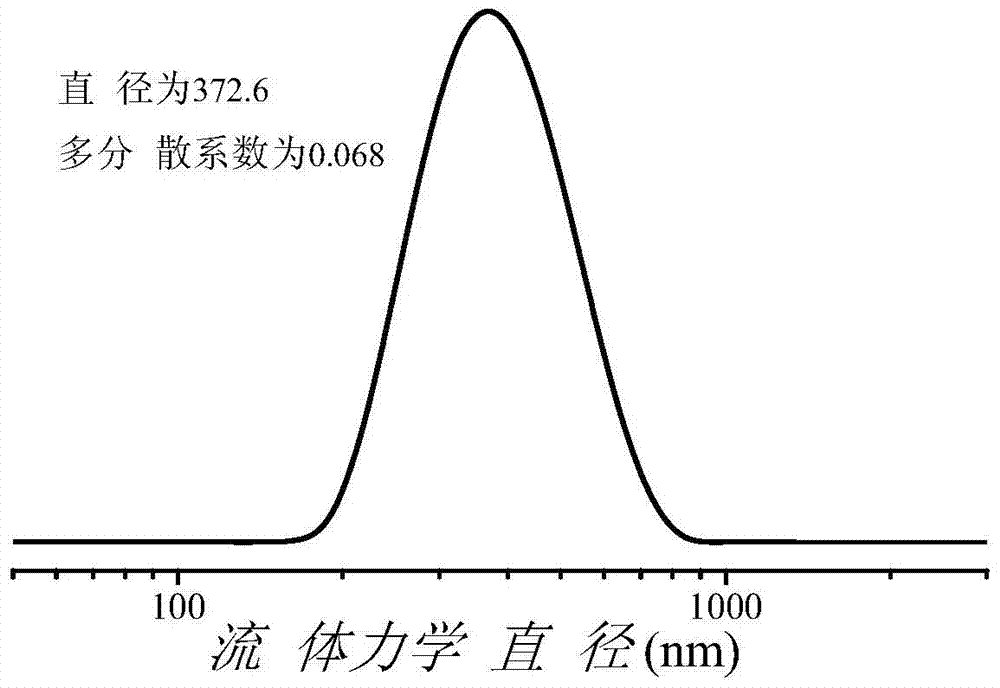

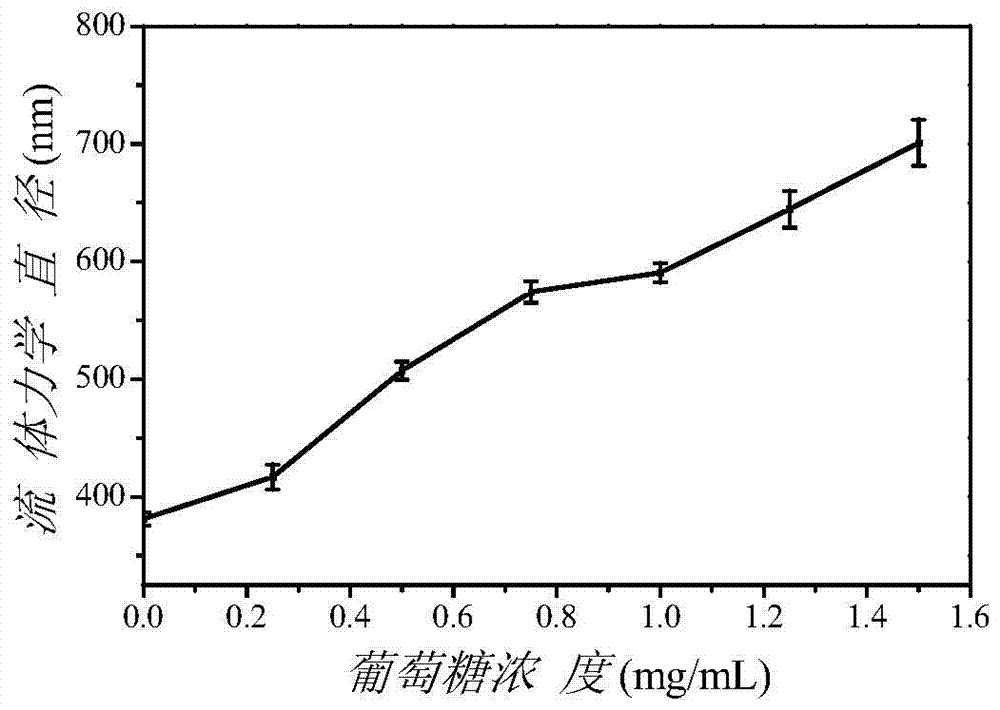

Embodiment 1

[0067] This embodiment provides a method for preparing sugar-responsive polymer vesicles, including the following steps:

[0068] (1) The synthesis steps of amphiphilic sugar-based polymer PEO-b-P (DEA-stat-CMA-stat-GlcEMA):

[0069] a. Use 0.409g (0.2mmol) of brominated polyoxyethylene (PEO-Br) as the macroinitiator, diethylaminoethyl methacrylate (DEA) (2.220g, 12mmol), coumarin monomer (CMA) (0.346g, 1.2mmol), glucose monomer (AcGlcEMA) (0.736g, 1.6mmol), catalyst cuprous bromide (0.028g, 0.2mmol) and catalyst ligand PMDETA (0.042g, 0.24mmol) together Add to a 25mL round-bottom flask, dissolve all the above-mentioned reactants with 3mL of dimethylformamide, bubbling argon for 30 minutes to remove oxygen in the reaction system (form an oxygen-free environment), proceed Atom transfer radical polymerization (ATRP), the reaction temperature is 75℃, the reaction time is 60h, after the reaction is over, a polymer solution is obtained;

[0070] b. The obtained polymer solution is succe...

Embodiment 2

[0078] This embodiment provides a method for preparing sugar-responsive polymer vesicles, including the following steps:

[0079] (1) The synthesis steps of amphiphilic sugar-based polymer PEO-b-P (DEA-stat-CMA-stat-GlcEMA):

[0080] a. Use 0.409g (0.2mmol) of brominated polyoxyethylene (PEO-Br) as the macroinitiator, diethylaminoethyl methacrylate (DEA) (3.700g, 20mmol), coumarin monomer (CMA) (0.864g, 3.0mmol), glucose monomer (AcGlcEMA) (1.472g, 3.2mmol), catalyst cuprous bromide (0.028g, 0.2mmol) and catalyst ligand PMDETA (0.042g, 0.24mmol) together Add to a 25mL round-bottom flask, dissolve all the above-mentioned reactants with 5mL anisole, bubbling argon for 30 minutes to remove oxygen in the reaction system, and carry out atom transfer radical polymerization (ATRP) ), the reaction temperature is 100°C, the reaction time is 40h, and the polymer solution is obtained after the reaction is completed;

[0081] b. The obtained polymer solution is successively subjected to rotary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com