Building floor corner cantilever outer frame supporting system

A support system and corner technology, which is applied in the direction of construction, building structure, scaffolding accessories, etc., can solve the problems of affecting bearing capacity, column reinforcement displacement, and non-adjustability, so as to increase the safety factor of operation, improve the bearing capacity, and facilitate The effect of material passing through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

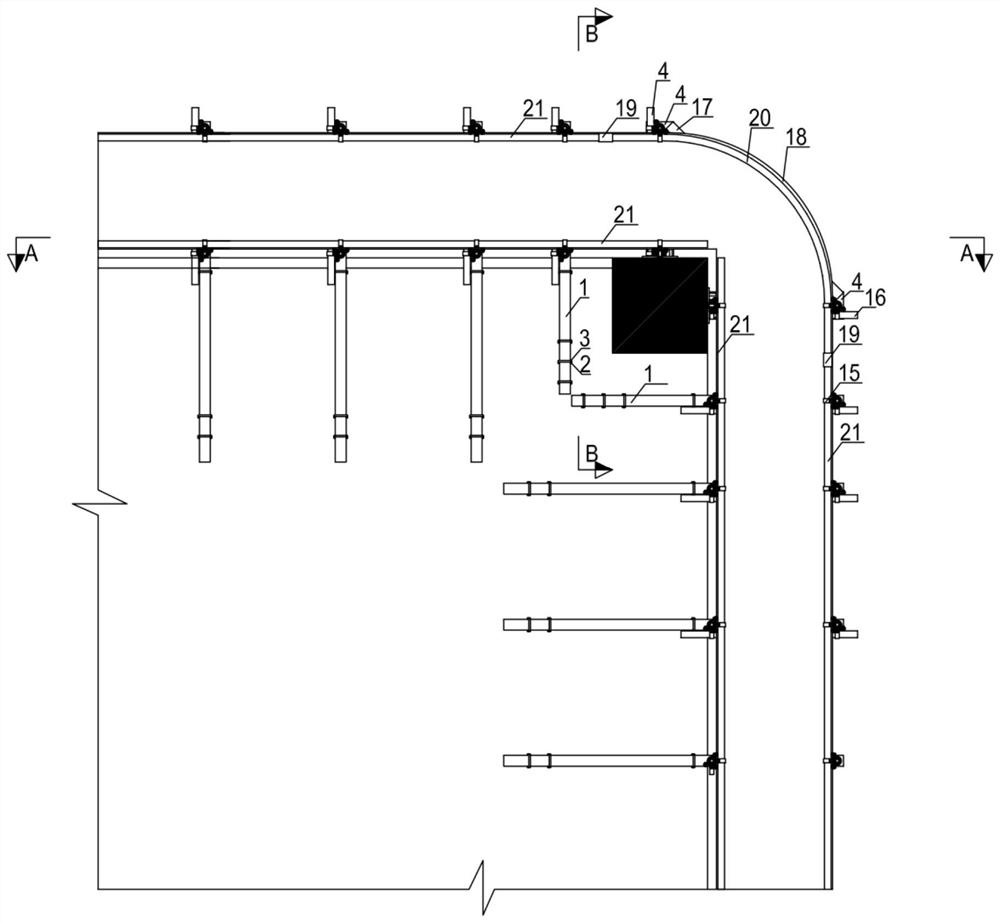

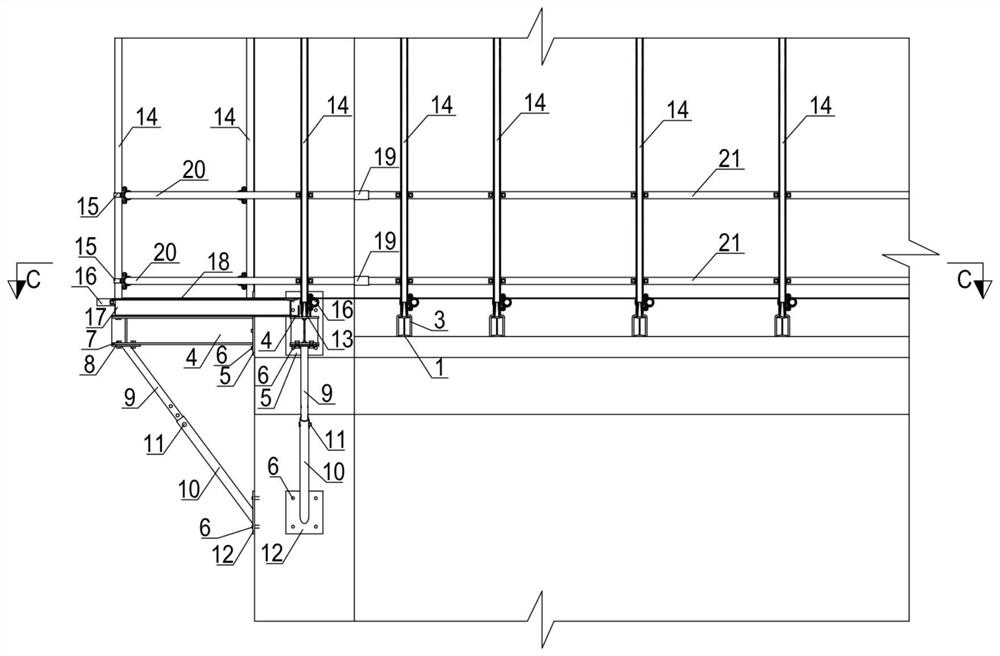

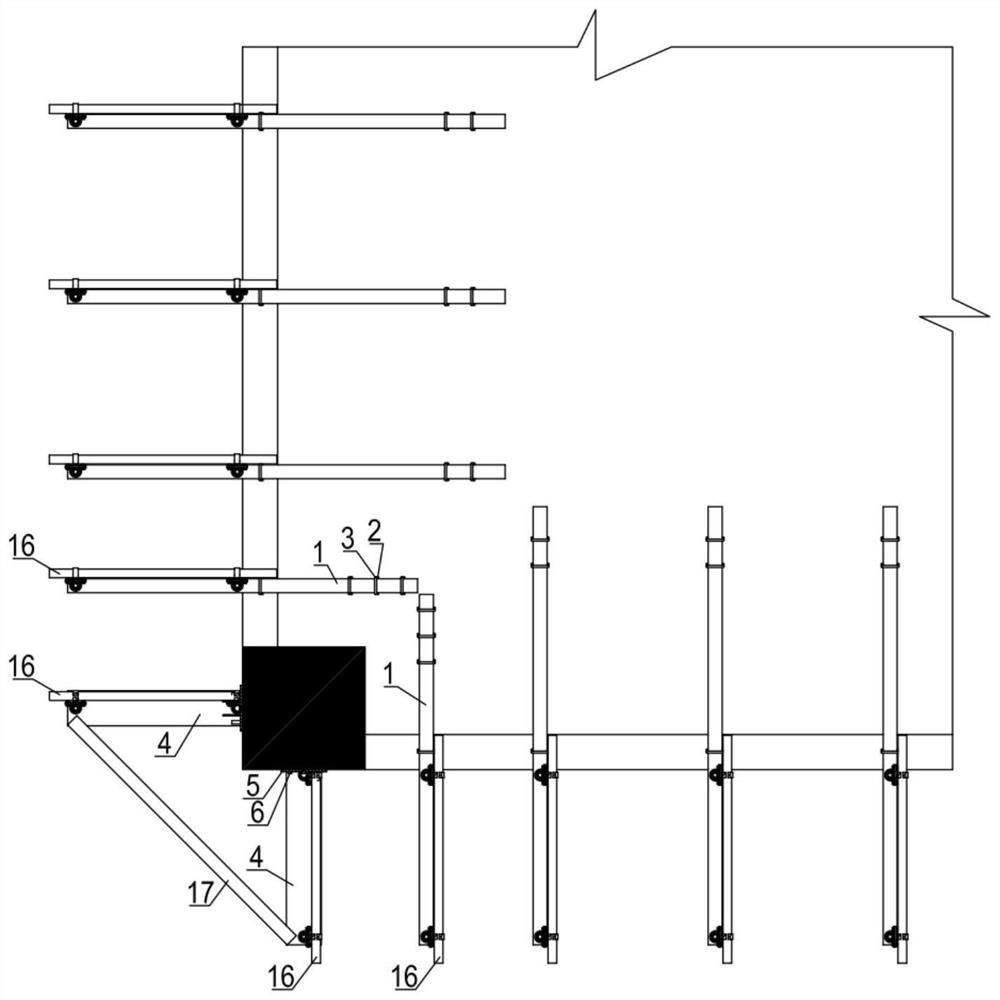

[0065] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

[0066] The invention provides a cantilevered external scaffold, which replaces the traditional floor-mounted scaffold, reduces the cost and increases the safety factor; at the corner of the external frame, a triangular support system with adjustable hypotenuse is adopted, and the I-shaped steel beam does not need to go deep into the building floor for anchoring , carried by the triangular support frame, which solves the difficulty of arranging the outer frame at the corner, and has a wide range of applications; the triangular support frame has a fixed shape and high stability. The triangular support frame, with adjustable hypotenuses, is suitable for the erection of the outer frame platform base when the facade is une...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com