Polymer system and preparation method thereof

A technology of polymers and polymer materials, applied in the field of polymer materials, can solve the problems of difficult regulation of the glass transition temperature of polymers and the inability to adapt to the needs of many occasions, and achieves the effects of good mechanical properties and easy shaping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Another aspect of the present invention provides a method for preparing the above-mentioned polymer system, comprising the following steps:

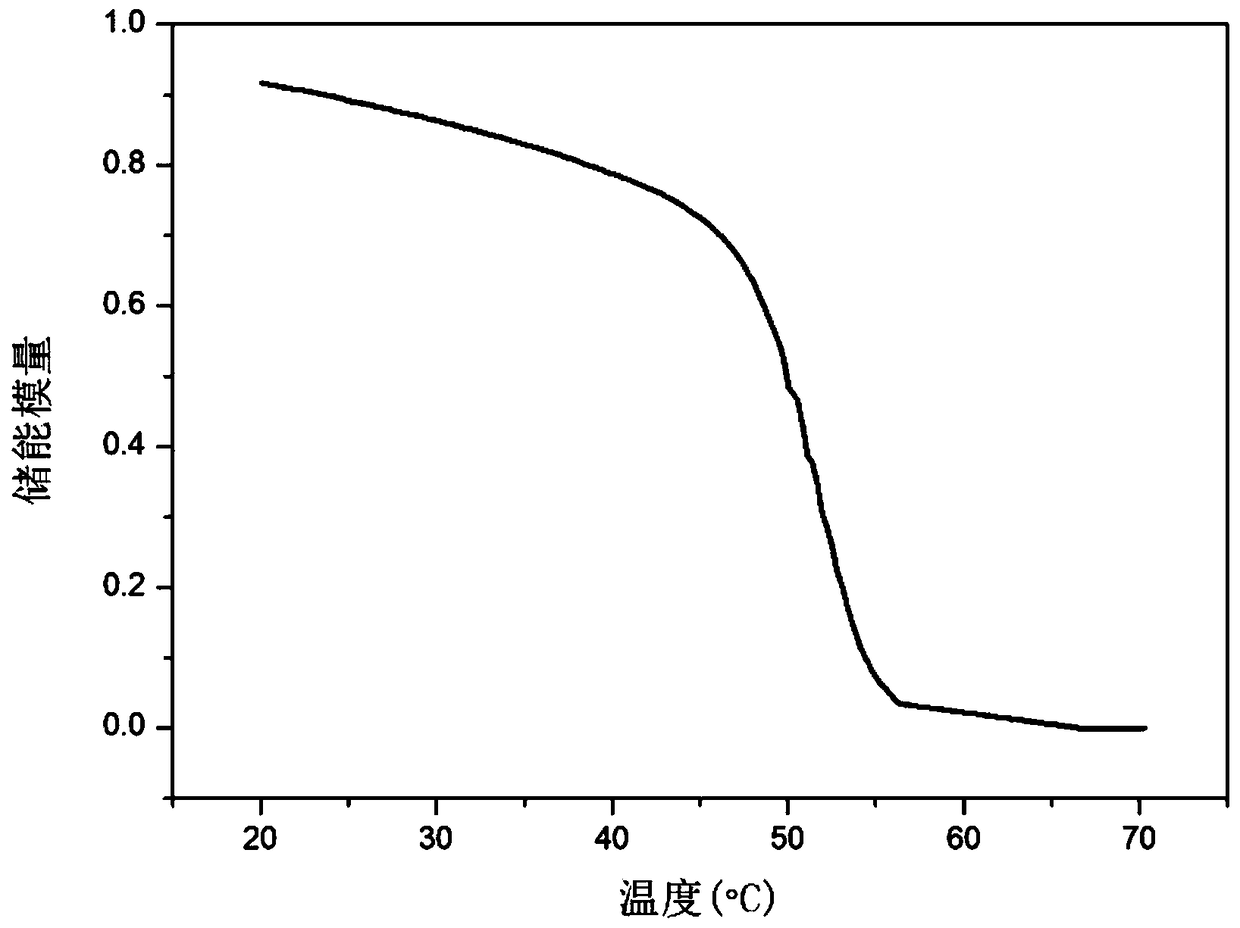

[0023] In the polymer system provided by the embodiment of the present invention, the polyol and the boron crosslinking agent form a boron ester bond, and the entire network structure of the polymer system is constructed through the boron ester bond, and the bond exchange temperature of the boron ester bond is relatively low , and the pH regulator can make the borate bond more stable. By selecting polyols, the temperature at which the borate bond can be exchanged can be determined and regulated. The plasticizing temperature is the borate bond in the polymer system. The temperature of the exchange; at the same time, the glass transition temperature of the polymer system is provided by the polyol part, and the control of the glass transition temperature can be easily realized through different types of organic substances. The glass ...

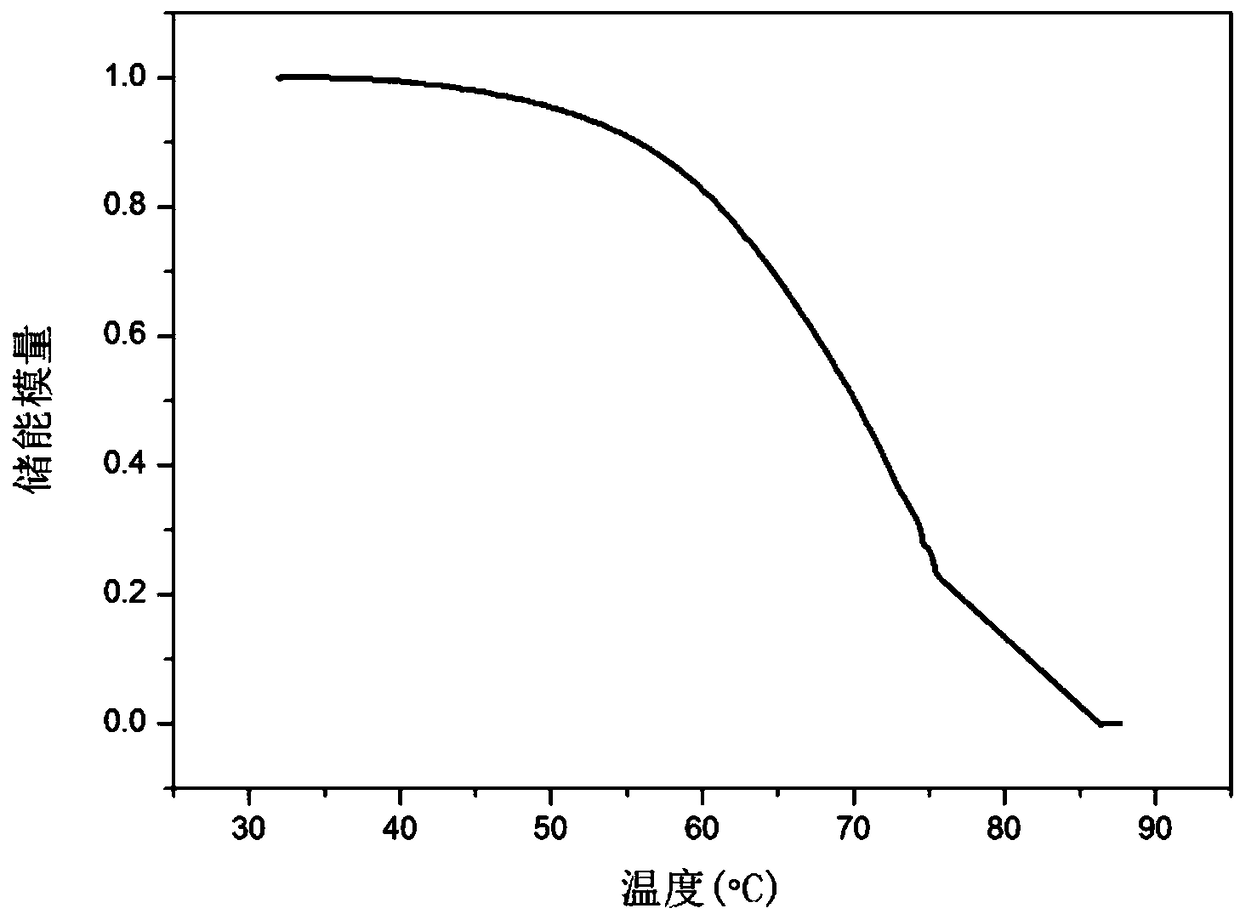

Embodiment 1

[0040] A polymer system, the raw materials are as follows:

[0041] a) p-(2,3-epoxypropyloxy)-N,N-bis(2,3-epoxypropyl)aniline, Sigma-Aldrich Company; the structural formula is as follows:

[0042]

[0043] b) 3-mercapto-1,2-propanediol, TCI company; the structural formula is as follows:

[0044]

[0045] c) trimethyl borate, TCI company; Structure is as follows:

[0046]

[0047] d) 1,8-diazabicyclo[5.4.0]undec-7-ene: TCI Company; the structural formula is as follows:

[0048]

[0049] Preparation:

[0050] Weigh 10.82 mmol of 3-mercapto-1,2-propanediol and 5.41 mmol of trimethyl borate, and stir until they are evenly mixed. Under cooling in a water bath, 3.69 mmol of 1,8-diazabicyclo[5.4.0]undec-7-ene was added and stirred evenly. Add 3.61 mmol of p-(2,3-epoxypropyloxy)-N,N-bis(2,3-epoxypropyl)aniline, stir it by magnetic force at 50°C, and seal the reaction for 1 hour. Pour it into an aluminum pan, react in an oven at 80°C for 8 hours, and dry it in a vacuum...

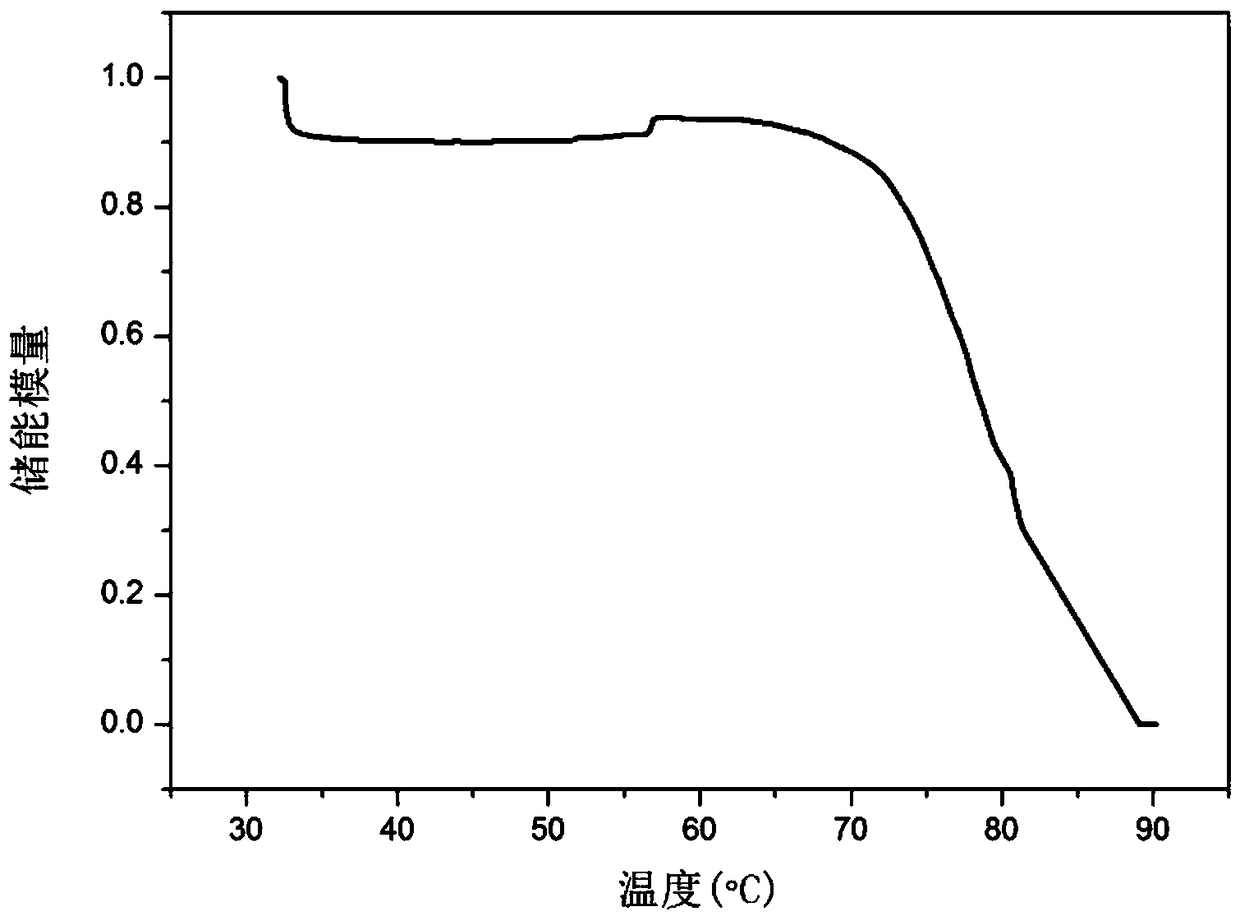

Embodiment 2

[0053] A polymer system, the raw materials are as follows:

[0054] a) p-(2,3-epoxypropyloxy)-N,N-bis(2,3-epoxypropyl)aniline, Sigma-Aldrich;

[0055] b) Bisphenol A diglycidyl ether, Sigma-Aldrich company; Structural formula is as follows:

[0056]

[0057] c) 3-mercapto-1,2-propanediol, TCI company;

[0058] d) trimethyl borate, TCI company;

[0059] e) 1,8-diazabicyclo[5.4.0]undec-7-ene, TCI Company;

[0060] Preparation:

[0061] Weigh 7.45 mmol of 3-mercapto-1,2-propanediol and 3.72 mmol of trimethyl borate, and stir until they are evenly mixed. Under cooling in a water bath, 2.54 mmol of 1,8-diazabicyclo[5.4.0]undec-7-ene was added and stirred evenly. Add 1.19mmol of p-(2,3-epoxypropyloxy)-N,N-bis(2,3-epoxypropyl)aniline and 1.94mmol of bisphenol A diglycidyl ether, at 50°C The reaction was sealed for 1 hour by magnetic stirring. Pour it into an aluminum pan, react in an oven at 80°C for 8 hours, and dry it in a vacuum oven at 120°C for 0.5 hour to obtain the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com