Fully-automatic production line of manufacturing chopsticks by using plant branches

A production line and fully automatic technology, which is applied to machine tools, metal processing equipment, and wood processing equipment suitable for grinding the edge of workpieces, can solve the problems of rough products, waste of human resources, and high costs, and achieve broad market prospects and save society Resource, energy efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

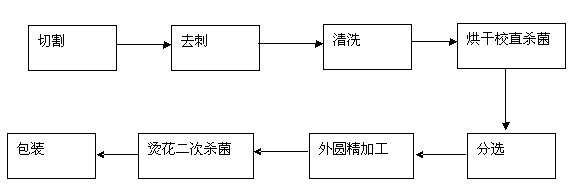

[0044] Such as Figure 1 The present invention is shown by cutting machine (1), destacker (2), cleaning machine (3), drying straightening sterilization machine (4), sorting equipment (5), outer circle processing machine (6) and ironing machine. The flower machine (7) is composed, and the machines of each level are connected by conveyor belts.

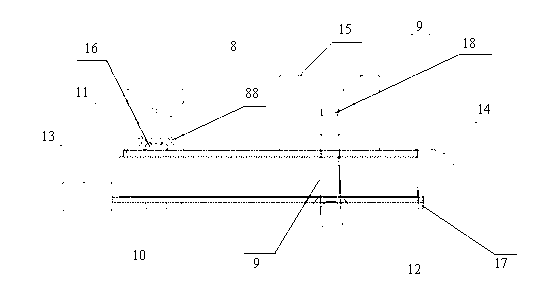

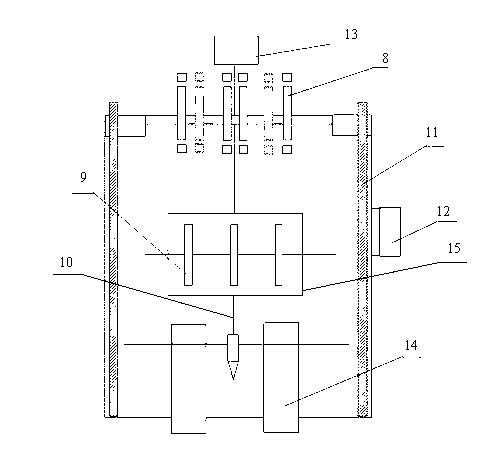

[0045] Put wormwood into the cutting machine (1) for cutting, adjust the distance between each group of grasping claws (8) to be 15cm, the distance between adjacent claws (84) to be 1cm, and the width of the claws (84) itself to be 2.5cm. The saw blade (9) is cut into 20cm wormwood stems, and enters the thorn removal stage; removes the burrs of the wormwood stems, polishes them evenly, and enters the cleaning stage; stirs in the cleaning tank for 5 minutes, and enters the drying, straightening and sterilization link; the stem bar reaches a saturated water absorption of 21%, and each microwave oven (33) works at 1000w, and it takes 3 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com