Method and device for preparing multi-scale functional microstructure on high-hardness surface

A microstructure and multi-scale technology, applied in microstructure devices, manufacturing microstructure devices, microstructure technology, etc., can solve the problems of high hardness surface wear, difficult heat dissipation, short service life, etc., to reduce friction, extend Long service life, the effect of reducing surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

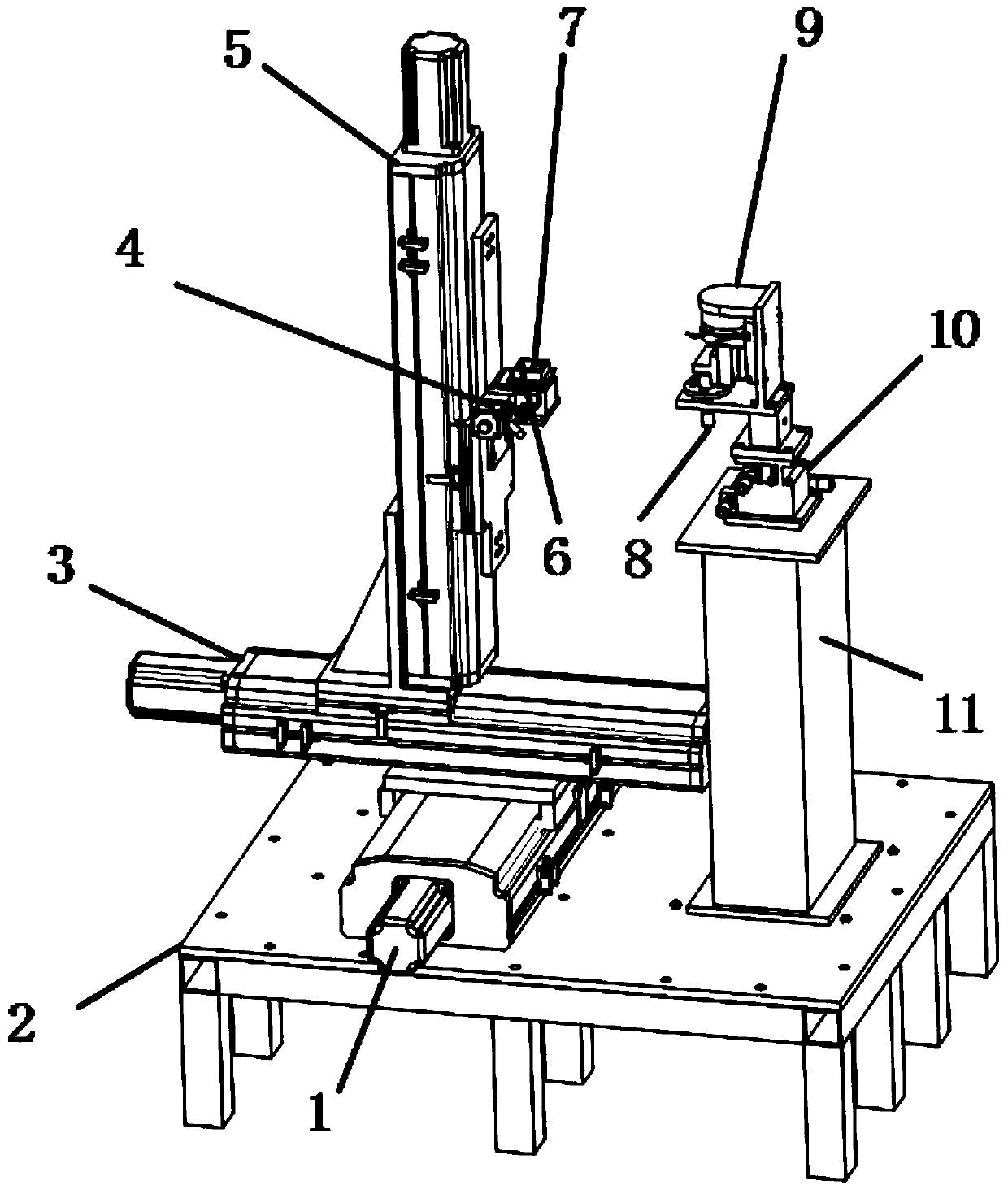

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] A method for preparing a multi-scale functional microstructure on a high-hardness surface, the specific steps are as follows:

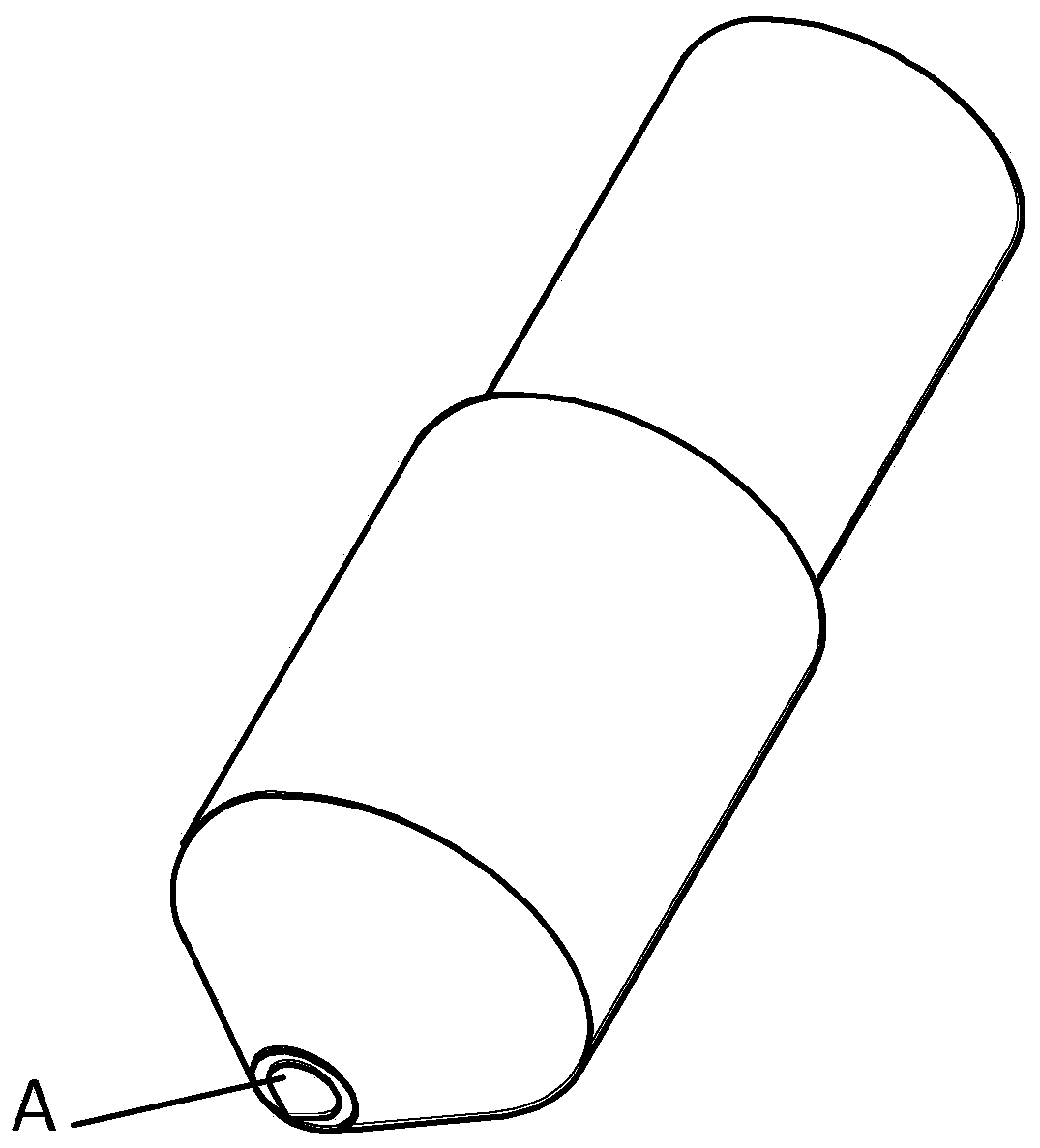

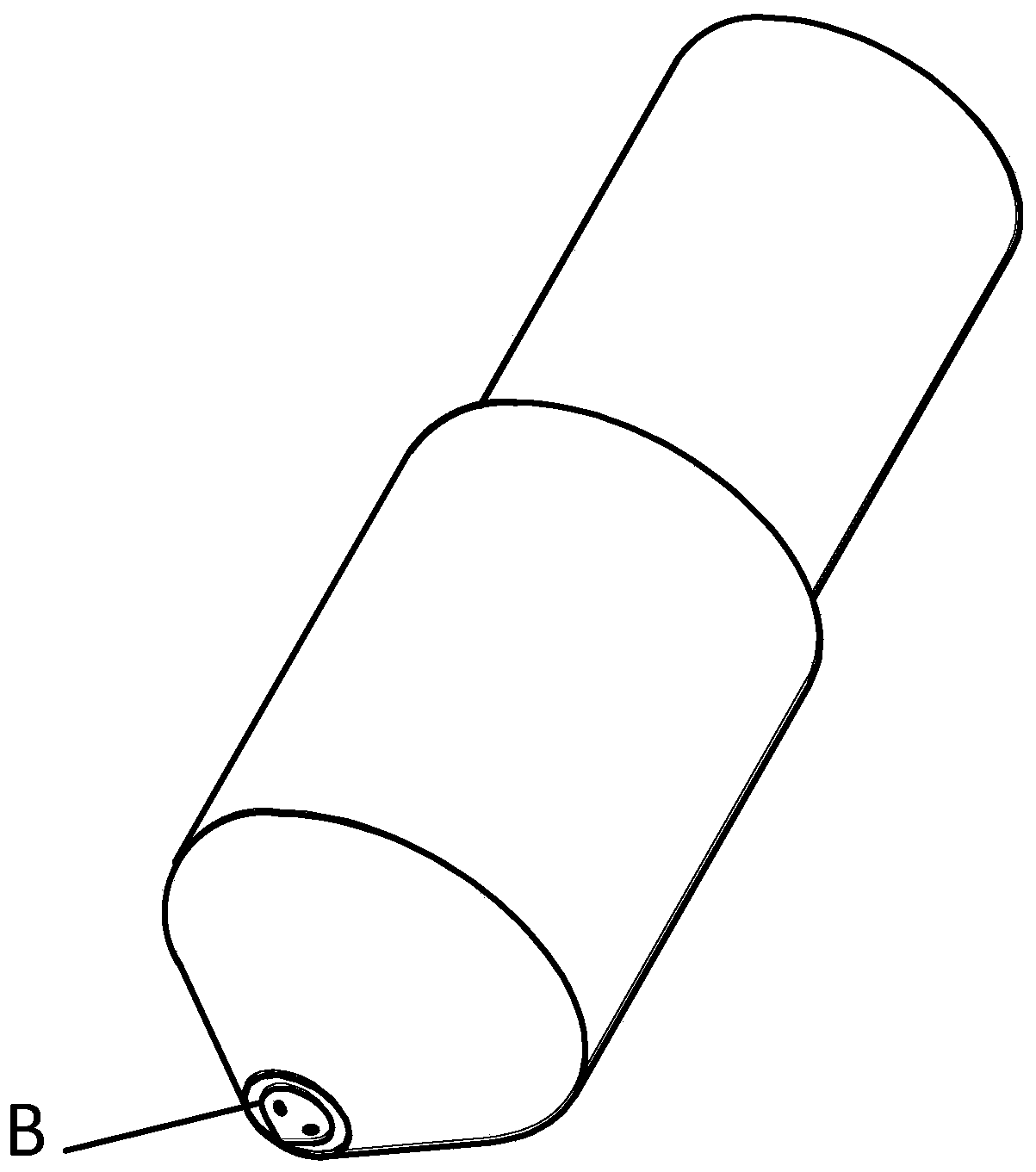

[0032] Step 1. Use diamond to make a single-point diamond tip, such as Figure 4 As shown, wherein, the single-point diamond tip is rounded truncated, the angle between the generatrix of the single-point diamond tip and the central axis is θ1=θ=22.5°, and the maximum diameter of the single-point diamond tip is d1=D=1.5mm; The minimum diameter of the single-point diamond tip d2 = d = 0.2mm; the height of the single-point diamond tip h1 = 1.5h = 1.5mm; then, the single-point diamond tip is sintered on a handle to make a single-point diamond tool (single-edged), such as figure 2 shown. Single-point diamond tools are used to fabricate functional microstructures at the millimeter-submillimeter scale.

[0033] Step 2, usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com