Composite inner and outer hydraulic pressure forming method for high-branch height thin-wall three-way pipe

A compound forming and three-way pipe technology, applied in the field of internal high pressure forming, can solve the problems of branch pipe height limitation, hindering the flow of pipe end materials, etc., achieve multi-axial feed rate, improve axial critical wrinkling stress, and lubricate effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

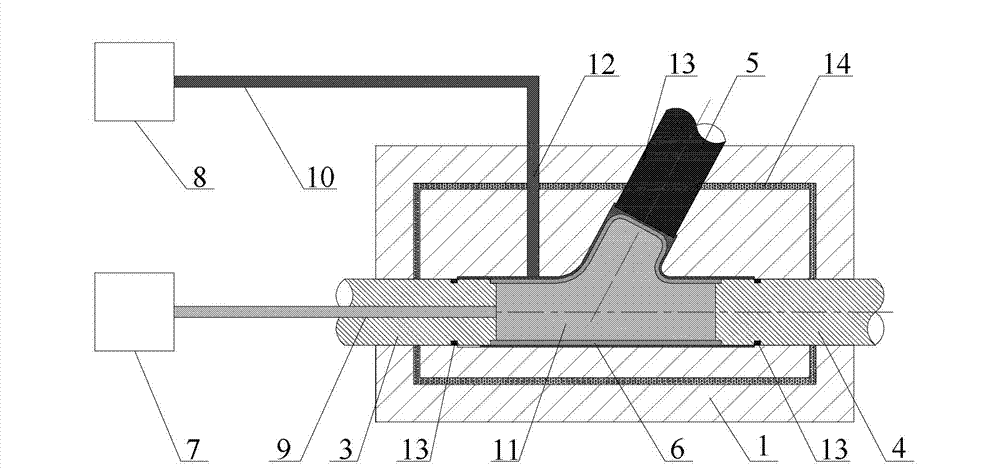

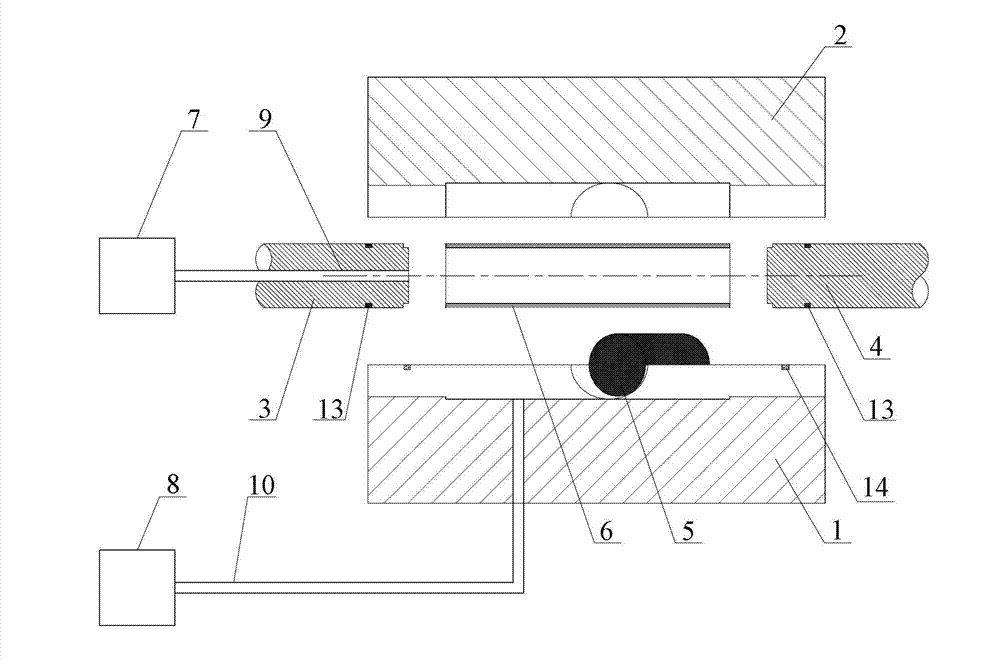

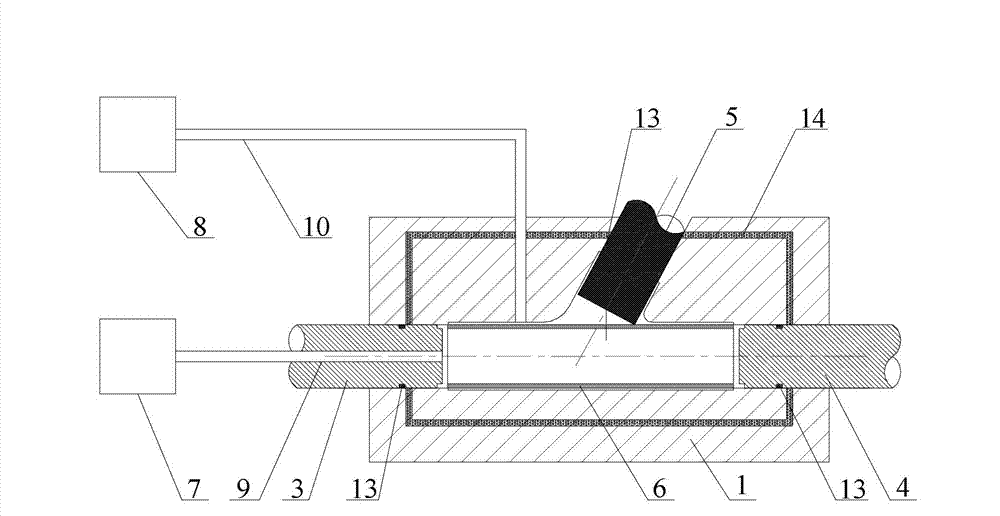

specific Embodiment approach 1

[0026] Specific implementation mode one: as Figures 1 to 7 As shown, a kind of high-branch height thin-walled tee pipe internal and external hydraulic composite forming method described in this embodiment is based on the lower die 1, the upper die 2, the left punch 3, the right punch 4 and the branch pipe. The forming die composed of punch 5 is realized; the left punch 3 has a first liquid passage 9 along its axial direction, and the first supercharger 7 communicates with the inner cavity of the tube blank 6 through the first liquid passage 9, which can be increased by The pressurizer 7 fills the inside of the tube blank 6 with a liquid medium 11 through the liquid channel 9 to apply internal pressure. There is a second liquid channel 10 on the lower mold 1, and the second booster 8 communicates with the tube blank 6 through the second liquid channel 10. The external cavity (that is, the entire cavity formed when the lower mold 1 and the upper mold 2 are closed) is connected,...

specific Embodiment approach 2

[0034] Embodiment 2: In step 4 of this embodiment, during the deformation process of the tube blank 6 , the difference between the internal pressure and the external pressure should ensure that the tube blank 6 can produce plastic deformation. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment three: In step four of this embodiment, the internal pressure of the tube blank (6) is always greater than the external pressure during the deformation process, and the internal pressure is 25% greater than the external pressure. Under the same conditions, the height of the branch pipe is increased by 18%. . Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com