Sliding component coated with metal-comprising carbon layer for improving wear and friction behavior by tribological applications under lubricated conditions

A sliding component and component technology, applied in the direction of metal material coating process, coating, engine components, etc., can solve problems such as coating denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

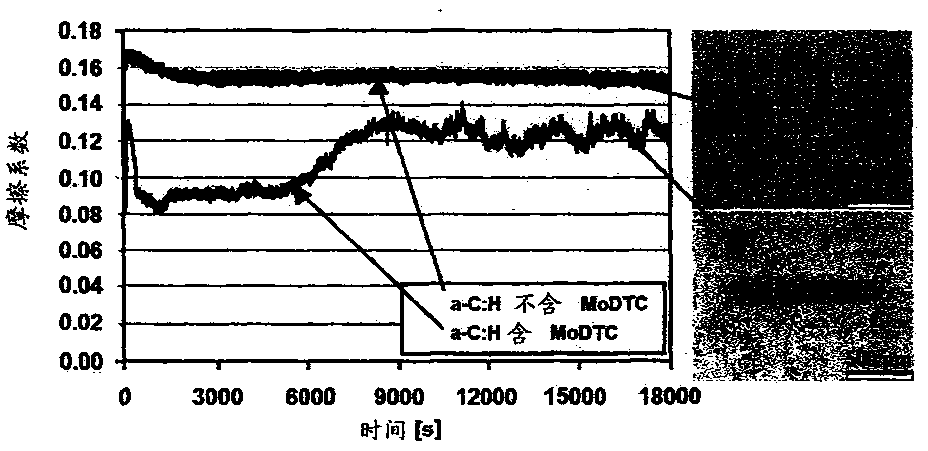

[0014] In order to overcome the drawbacks of DLC coatings interacting with lubricants containing Mo-containing and / or Zn-containing additives, the inventors aimed to design a new metal-doped modified DLC coating that can impart The chemical affinity of the additives thus provides better friction and wear properties compared to the prior art.

[0015] As mentioned earlier, a-C:H:Me coatings with an atomic ratio of Me-C not greater than 20% are known from the prior art for the coating of sliding components to improve wear and friction properties, however, these coatings (similar to metal-free a-C:H coatings) are incompatible with lubricants containing Mo-containing and / or Zn-containing additives.

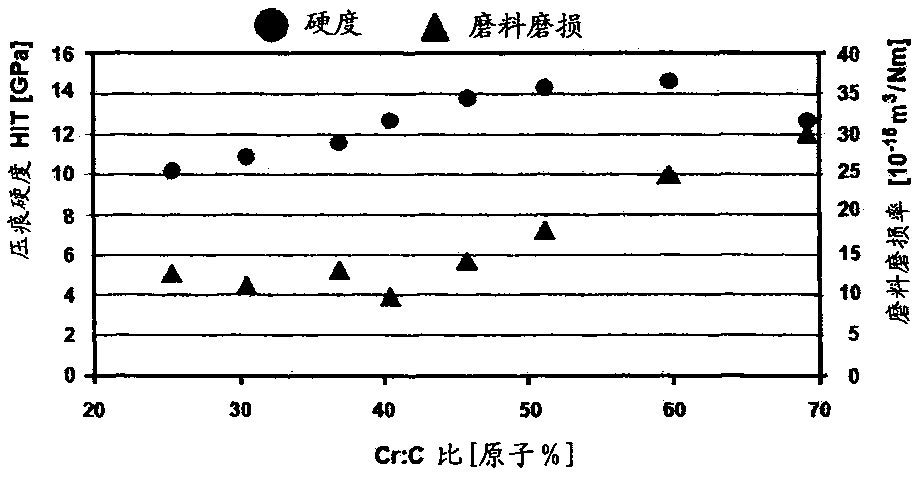

[0016] The inventors have unexpectedly found that metal-doped DLC coatings having an atomic percentage of Me:C greater than or equal to 30% and less than or equal to 60% show a positive interaction with lubricants containing Mo-containing and / or Zn-containing additives effect and thu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com