Numerical control lathe for automatically machining cylindrical roller for bearing

A cylindrical roller and automatic processing technology, applied in the field of lathes, can solve the problems of low service life of lathes, easy wear of multiple parts, slow motor speed, etc., and achieve the effects of small frictional impact, small falling space, and increased processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

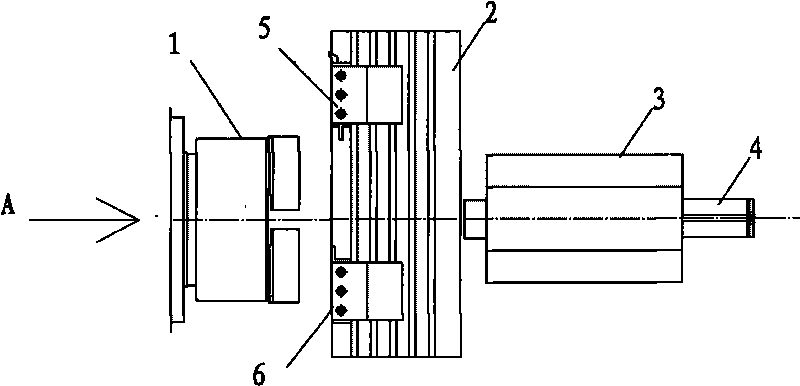

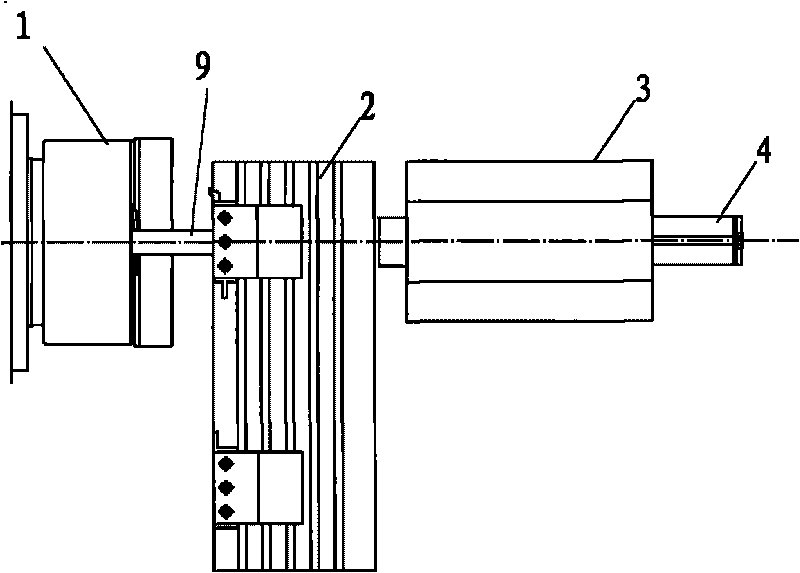

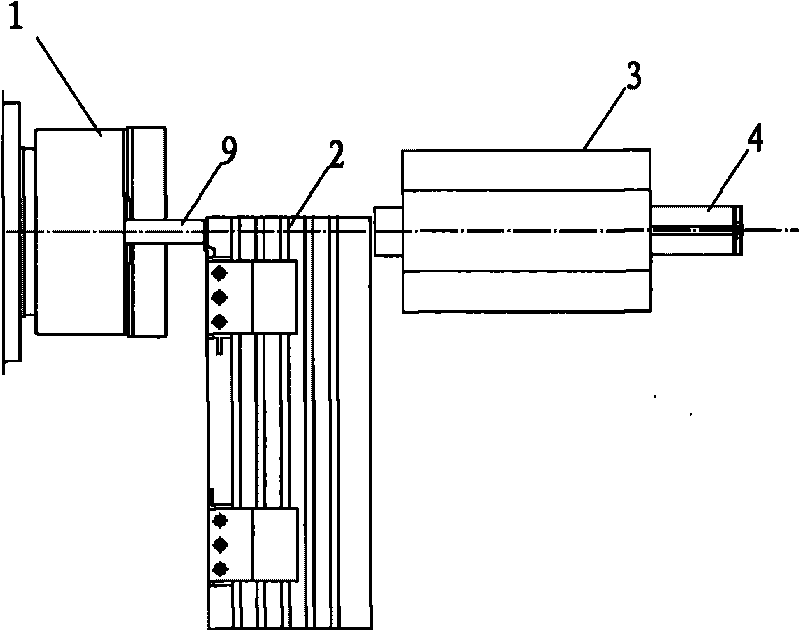

[0031] Such as Figure 9 As shown, the present invention is a numerically controlled lathe for automatically processing cylindrical rollers for bearings. The main body unit of the lathe includes a machine base 30, a workbench positioned on the machine base 30, a chuck assembly 14 for clamping a bar, and a driving chuck. The motor unit that the disc assembly 14 rotates, and the fixed cutter assembly ( Figure 9 not shown). In the figure, numeral 13 represents the position of the motor unit and its headstock. In the prior art, there is already a chuck assembly with a central hole passing through front and rear, and a drive motor thereof; the central hole is used as a space for conveying and clamping the bar. Thus as Figure 8 As shown, the bar is fed from the rear side A and sent to the right side of the chuck to facilitate the processing of the right tool.

[0032] In order to achieve the purpose of automatic production, the present invention sets a material holding unit, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com