Semimetal brake pad and preparation method thereof

A technology of brake pads and semi-metal, which is applied in the field of semi-metal brake pads and its preparation, can solve the problems of poor heat dissipation and low strength of friction materials, and achieve the effects of easy operation, good mechanical properties and meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

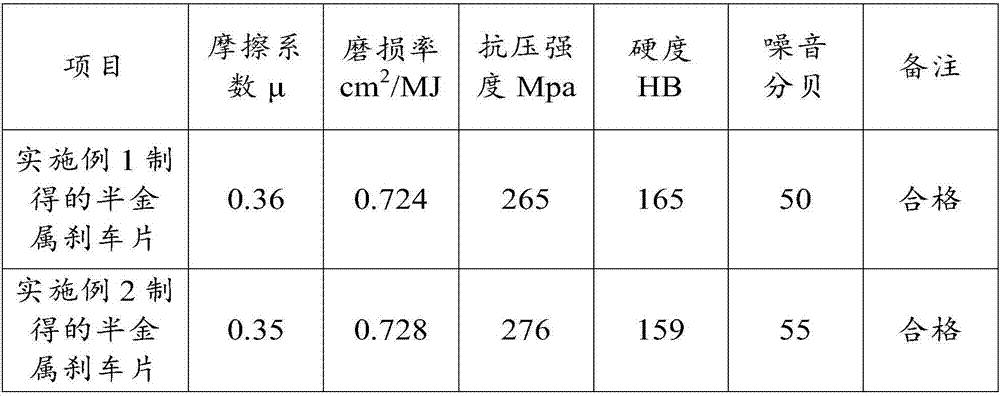

Examples

Embodiment 1

[0032] A semi-metallic brake pad, including a stainless steel back plate and a friction block, the raw materials for preparing the friction block and their mass percentages are: 44% iron powder, 9.14% steel fiber, 6.86% copper-based fiber, 6% jute fiber, chromous acid Ferrous 4%, epoxy resin 17%, fluorine rubber powder 3.75%, nitrile rubber powder 1.5%, nitrile rubber powder 0.75%, silica airgel 0.5%, silicon carbide 2%, nano-titanium dioxide 3%, Maleic anhydride 0.6%, imide 0.4%, graphene 0.5%. Among them, the specific surface area of silica airgel is 400m 2 / g, the density is 60kg / m 3 ; Graphene is a stack of carbon atoms with 3 to 10 layers of benzene ring structure.

Embodiment 2

[0034] A semi-metallic brake pad, including a stainless steel back plate and a friction block, the raw materials for preparing the friction block and their mass percentages are: iron powder 53%, steel fiber 7.29%, copper-based fiber 6.07%, aluminum-based fiber 3.64%, jute fiber 2%, ferrous chromite 3%, epoxy resin 15%, fluororubber powder 2.75%, nitrile rubber powder 1.57%, nitrile rubber powder 1.18%, silica airgel 0.6%, silicon carbide 1% , nano titanium dioxide 2%, maleic anhydride 0.18%, imide 0.21%, methyl acrylate 0.11%, graphene 0.4%. Among them, the specific surface area of silica airgel is 500m 2 / g, the density is 50kg / m3; graphene is a carbon atom stacked by 3 to 10 layers of benzene ring structure.

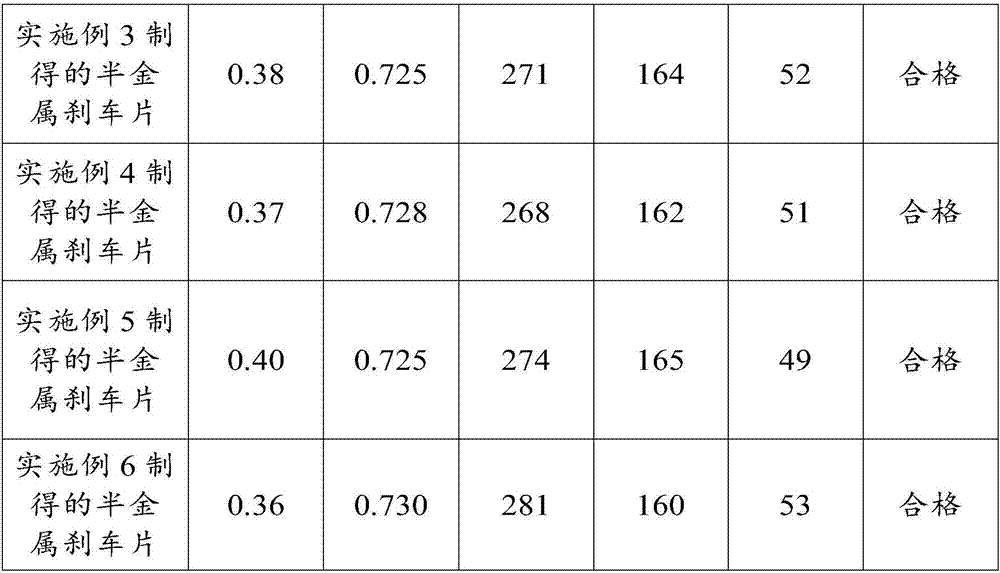

Embodiment 3

[0036] A semi-metallic brake pad, including a stainless steel back plate and a friction block, the raw materials for preparing the friction block and their mass percentages are: iron powder 56%, steel fiber 7%, copper-based fiber 5.6%, aluminum-based fiber 1.4%, jute fiber 5%, ferrous chromite 2%, epoxy resin 13%, fluororubber powder 2.18%, nitrile rubber powder 1.09%, nitrile rubber powder 0.73%, silica airgel 0.3%, silicon carbide 3% , nano titanium dioxide 1%, maleic anhydride 0.6%, imide 0.6%, methyl acrylate 0.3%, graphene 0.2%. Among them, the specific surface area of silica airgel is 450m 2 / g, the density is 55kg / m3; graphene is a carbon atom stacked by 3 to 10 layers of benzene ring structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com