Testing apparatus for evaluating drag-reduction effects of bionic non-smooth surface and bionic jet surface

A non-smooth surface, test device technology, used in fluid dynamics tests, measuring devices, testing of machine/structural components, etc., can solve problems such as drag reduction, difficult maintenance, and cumbersome operations, and achieve lower operating costs. The effect of working reliability, simple replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

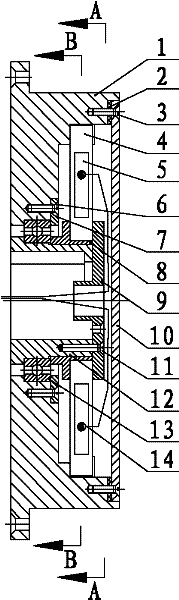

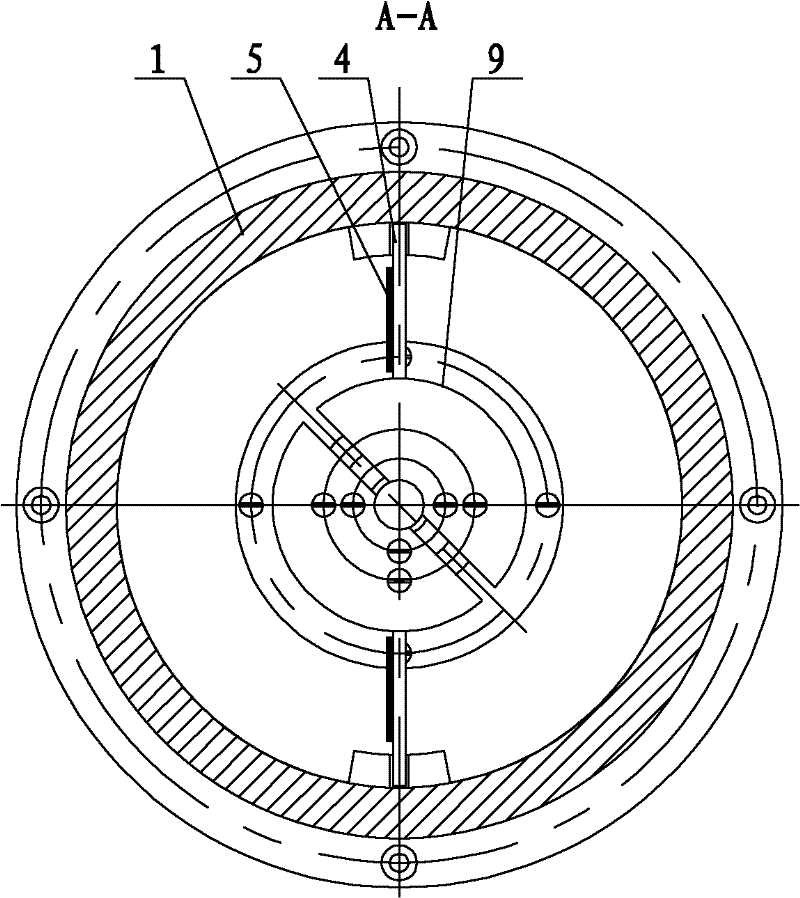

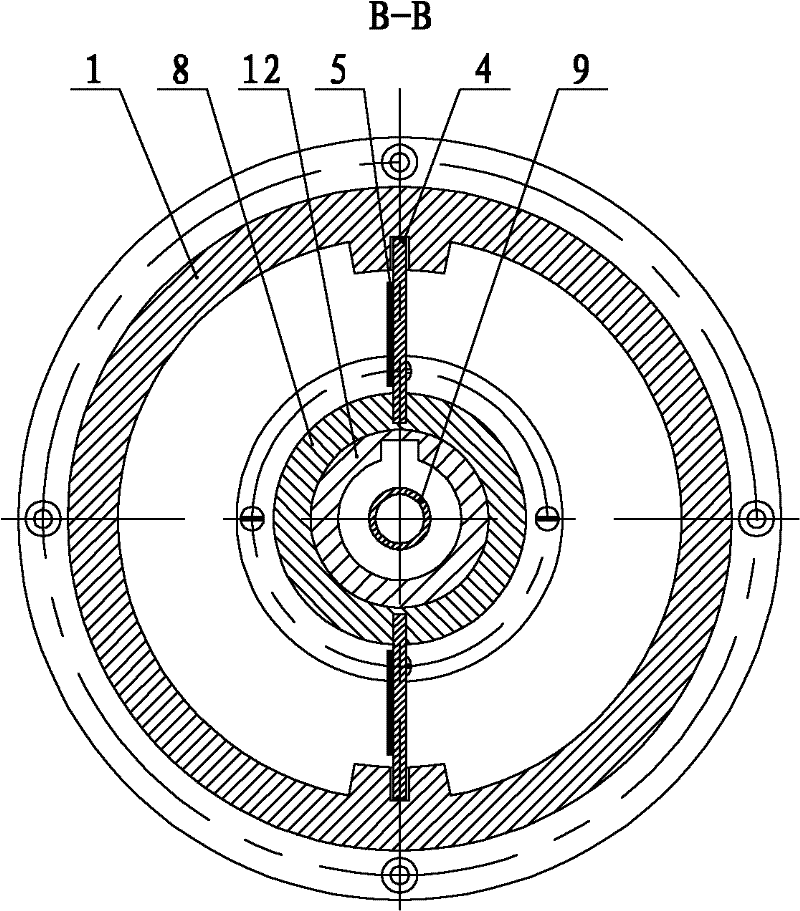

[0036] The specific implementation process of the present invention will be described below in conjunction with the accompanying drawings.

[0037] In the figure: 1. Sensor shell, 2. Sealing gasket, 3. Countersunk screw, 4. Driving lever, 5. Strain gauge, 6. Countersunk screw, 7. Bearing end cover, 8. Driving lever bracket, 9. Baffle, 10. Sealing end cover, 11. Countersunk head screw, 12. Sensor inner shell, 13. Bearing, 14. Cable, 15 Water tank, 16. Sealing gasket, 17. Countersunk head screw, 18. Bearing end cover , 19. Sealing end cover, 20. Jet inlet pipeline, 21. Sealing gasket, 22. Bearing, 23. Sealing gasket, 24. Waterproof bearing, 25. Permanent magnet (N-S), 26. Pole plate, 27. Countersunk screw, 28. Right end cover of sealing chamber, 29. Jet seal, 30. Countersunk screw, 31. Test sample, 32. Bolt, 33. Sealing gasket, 34. Sealing chamber, 35. Elastic retainer for shaft Ring, 36. Sealing shaft, 37. End cover of sealing body, 38. Retaining ring for hole, 39. Retaining r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com