Open gear lubricant combination and preparation method thereof

A lubricating oil composition and open gear technology, applied in the field of lubricating oil, can solve the problems of unfavorable site cleaning and sanitation, limited operating temperature range, poor low-temperature fluidity, etc., and achieve excellent low-temperature fluidity, safe use, and high viscosity index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In addition, the present invention also provides a preparation method of an open gear lubricating oil composition, which includes the following steps: adding a high-viscosity synthetic base oil with a weight ratio of (55-93): (5-25): (2-20) , synthetic ester base oil and additives are mixed, heated to 70-120° C., and cooled to obtain an open gear lubricating oil composition.

[0028] Wherein, the high-viscosity synthetic base oil is preferably one or more of olefin copolymerized base oil, polyester base oil and natural gas synthetic base oil. As a preference, the olefin copolymer base oil has a viscosity grade of 40~1000mm 2 / s polyalphaolefin, the viscosity grade is 40~2000mm 2 / s ethylene α-olefin copolymer base oil or viscosity grade 40~2000mm 2 / s polybutene base oil; the viscosity grade of the polyester base oil is 100~1000mm 2 / s; the viscosity grade of the natural gas synthetic base oil is preferably 26 ~ 30mm 2 / s. The synthetic ester base oil is preferably...

Embodiment 1

[0034] Ethylene α-olefin copolymer base oil 2000: 77.95g

[0035] Trimethylolpropane fatty acid ester: 15g

[0036] Extreme pressure antiwear agent sulfurized isobutylene: 3g

[0037] Extreme pressure antiwear agent ammonium thiophosphate: 1g

[0038] Extreme pressure antiwear agent Thiophosphoric acid nitrogen-containing derivative: 0.5g

[0039] Benzotriazole fatty acid ammonium salt: 0.3g

[0040] Sulfurized Olefin Cottonseed Oil: 1g

[0041] Benzotriazole derivatives: 0.05g

[0042] Rust inhibitor alkenyl succinic acid: 0.1g

[0043] Rust inhibitor calcium sulfonate: 0.1g

[0044] Phenolic antioxidant T501: 0.5g

[0045] Amine antioxidant T531: 0.5g

[0046] The production process is as follows: mix ethylene α-olefin copolymer base oil and trimethylolpropane fatty acid ester according to the above weight parts, heat up to 120°C to remove moisture, cool down to 60~80°C, add extreme pressure antiwear agent vulcanized isobutylene , extreme pressure antiwear agent amm...

Embodiment 2

[0051] Ethylene α-olefin copolymer base oil 1100: 75.35g

[0052] Pentaerythritol complex ester: 15g

[0053] Extreme pressure antiwear agent Sulfurized isobutylene: 4g

[0054] Extreme pressure antiwear agent tricresyl phosphate: 0.9g

[0055] Extreme pressure antiwear agent ammonium thiophosphate: 1g

[0056] Extreme pressure antiwear agent aminothioester: 1g

[0057] Benzotriazole fatty acid ammonium salt: 0.5g

[0058] Sulfurized Olefin Cottonseed Oil: 0.8g

[0059] Benzotriazole derivatives: 0.05g

[0060] Thiadiazole derivatives: 0.1g

[0061] Rust inhibitor alkenyl succinic acid: 0.15g

[0062] Rust inhibitor calcium sulfonate: 0.15g

[0063] Phenolic antioxidant T501: 0.5g

[0064] Amine antioxidant T531: 0.5g

[0065] Production technology is identical with embodiment 1.

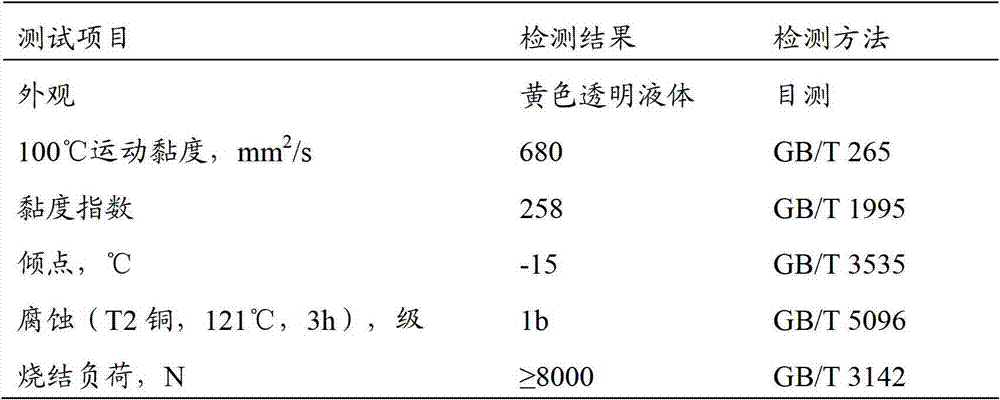

[0066] The properties of the open gear lubricating oil composition prepared in this example were measured, and the results are shown in Table 2.

[0067] The performance result of the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com