Non-smooth surface fluid friction resistance testing device and testing method

A non-smooth surface, fluid friction technology, used in fluid dynamics tests, measuring devices, testing of machine/structural components, etc. Research immaturity and other issues to achieve reliable test results, easy operation, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

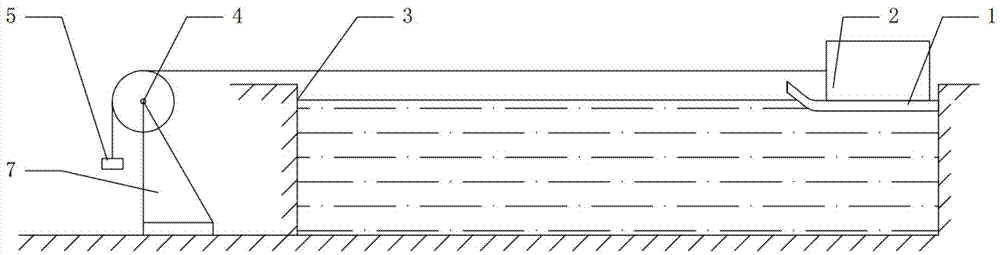

[0019] combine figure 1 , the present invention includes non-smooth surface plate 1, buoyancy material 2, pool 3, fixed pulley 4, weight 5, timer, support 7. The weight 5 bypasses the fixed pulley 4 and the buoyancy material 2 is connected together with a stay wire, the buoyancy material 2 is fixedly connected with the non-smooth surface plate 1, and the fixed pulley 4 is fixed on the support 7.

[0020] Wherein, the front end of the non-smooth surface plate 1 is tilted at a certain angle to reduce or eliminate the pressure difference resistance between the non-smooth surface plate 1 and the buoyancy material 2; Ensure that the pulling force received by the buoyancy material 2 is equal to the gravity of the weight 5; the length of the pool 3 is greater than the height H of the weight 5 from the ground, so as to ensure sufficient timing time and reduce timing erro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com