Self-lubricating sliding bearing material and its preparation method

A sliding bearing, self-lubricating technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as peeling of adhesive layers, bearing failure, different proportions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

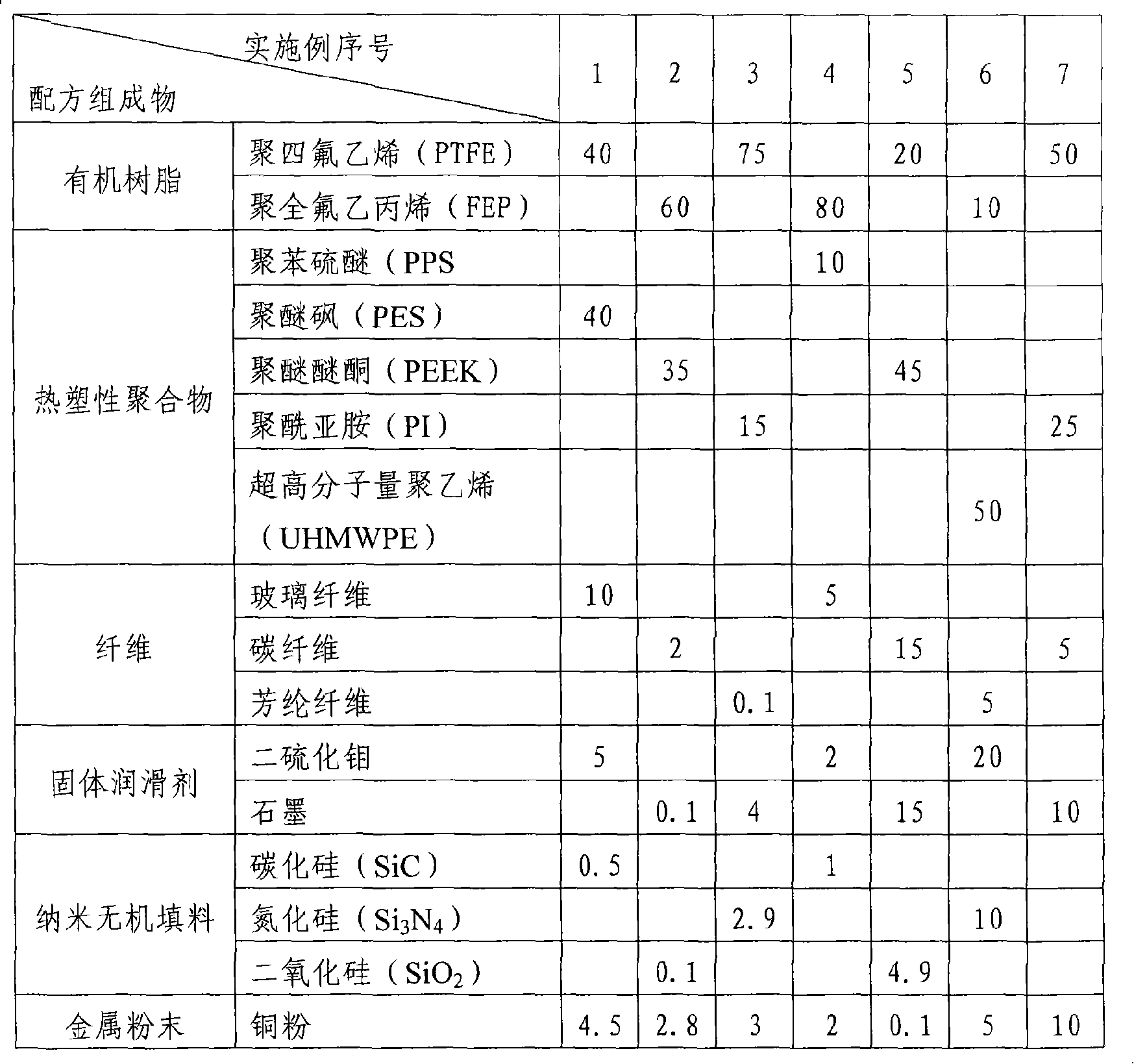

[0022] Example 1: Weigh according to the implementation formula Table 1, and mix evenly in a mechanical stirrer; after the surface of the low-carbon steel plate 2 with a thickness of 0.80 mm is sandblasted, phosphating is carried out. Spread the uniform mixture on the treated low-carbon steel plate 2 to form a self-lubricating sliding layer 1 (as shown in Figure 1), then dry it in a mesh belt drying furnace, and then rough roll it after drying. Carry out sintering and solidification in a sintering furnace, and then quickly roll it into the required bearing material with a thickness of 1.0mm.

Embodiment 2

[0023] Example 2: Weigh according to the implementation formula Table 2, and mix evenly in a mechanical stirrer; after sandblasting the surface of the stainless steel plate 2 with a thickness of 1.2mm, carry out pickling. Spread the uniform mixture on the treated stainless steel plate 2 to form a self-lubricating sliding layer 1 (as shown in Figure 1), then dry it in a mesh-belt drying furnace, rough roll after drying, and then sinter It is sintered and solidified in the furnace, and then quickly rolled into the required bearing material with a thickness of 1.5mm.

Embodiment 3

[0024] Example 3: Weigh according to the implementation formula Table 3, and mix evenly in a mechanical stirrer; after blasting the surface of the copper alloy plate 2 with a thickness of 1.6mm, carry out pickling. Spread the uniform mixture on the treated copper alloy plate 2 to form a self-lubricating sliding layer 1 (as shown in Figure 1), then dry it in a mesh-belt drying furnace, carry out rough rolling after drying, and then Carry out sintering and solidification in a sintering furnace, and then quickly roll it into the required bearing material with a thickness of 2.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com