Flat plate wall fluid friction resistance mensuring device based on open circulation

A technology of fluid friction and measuring devices, which is applied in measuring devices, fluid dynamics tests, and testing of machine/structural components, etc. It can solve the problems of not measuring single-measurement wall resistance, large test model size, and difficult production, etc., to achieve measurement Reliable, easy to operate and control, convenient card installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

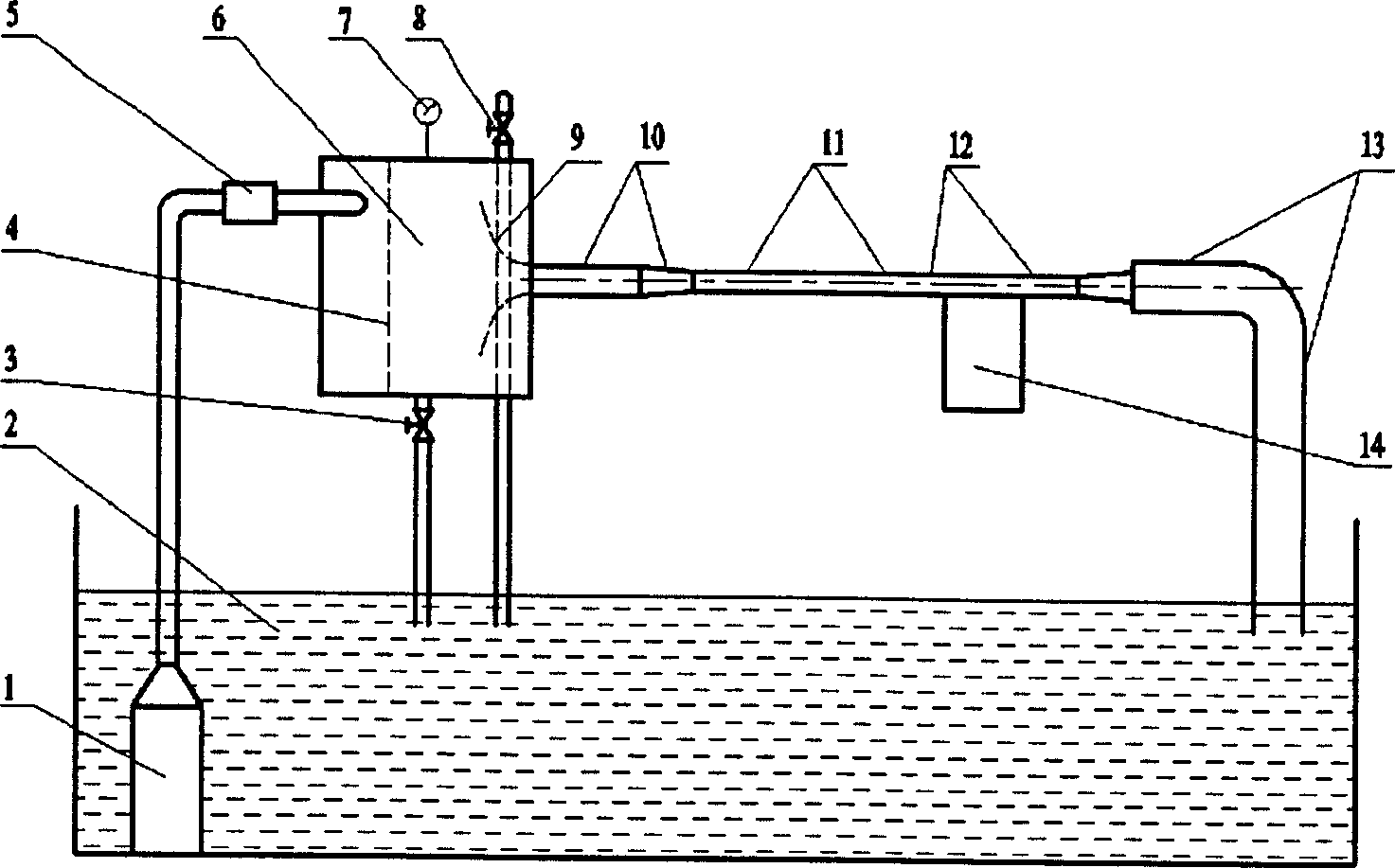

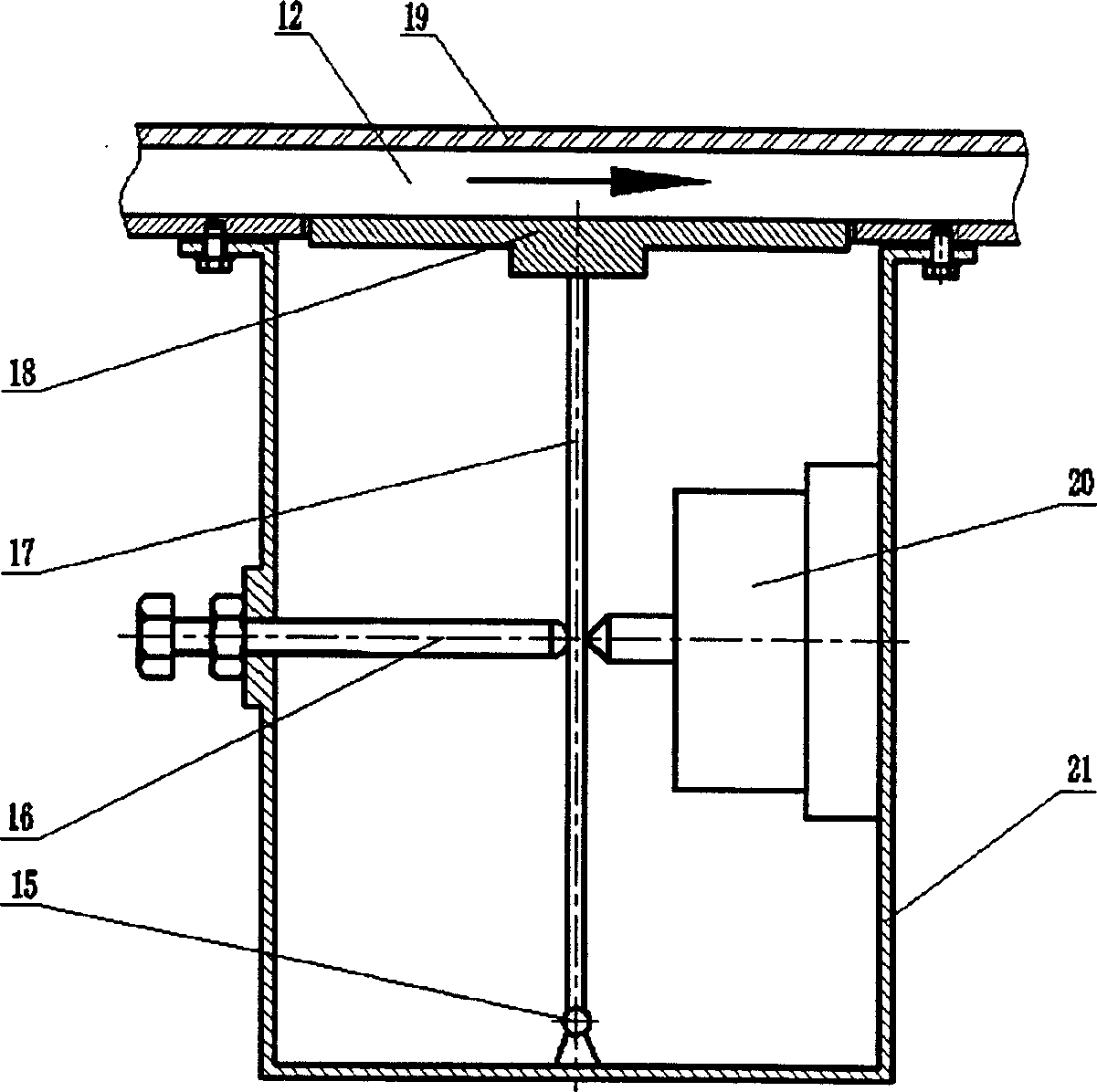

[0015] The flat wall fluid frictional resistance measurement device based on the open cycle proposed by the present invention has a structure such as figure 1 shown. It includes a pool 2, a buffer tank 6, a water flow pipeline and a load cell 14. The water inlet end of the buffer water tank 6 communicates with the pool 2 through the water pump 1 and the pipeline. The buffer water tank is provided with a partition 4, and the partition 4 is provided with a round hole. The water outlet of the buffer water tank 6 passes through the guide provided in the buffer water tank The flow pipe 9 communicates with the water flow pipeline, and the water flow pipeline communicates with the pool 2 through the elbow 13 . The water flow pipeline is composed of a variable diameter section 10, a development section 11 and an experimental section 12. The experimental section 12 has a rectangular cross-section, and the tested flat test piece 18 is placed in the experimental section 12 and becomes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com