Detector for round cross section sample wall surface fluid friction resistance

A fluid friction, circular cross-section technology, used in measuring devices, fluid dynamics tests, testing of machine/structural components, etc., can solve problems such as inability to meet the needs of technological development, achieve simple structure, reduce impact, disassembly and assembly handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

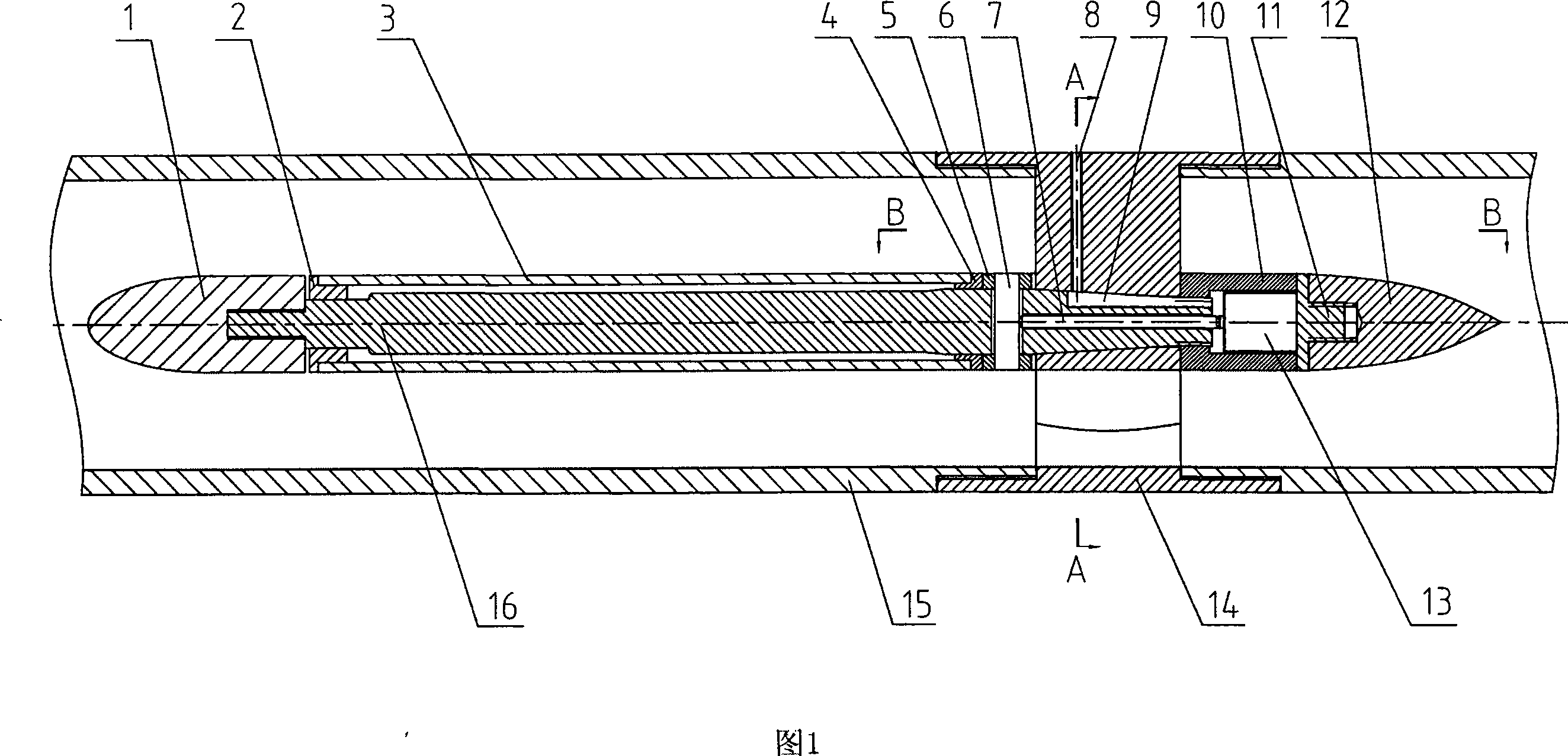

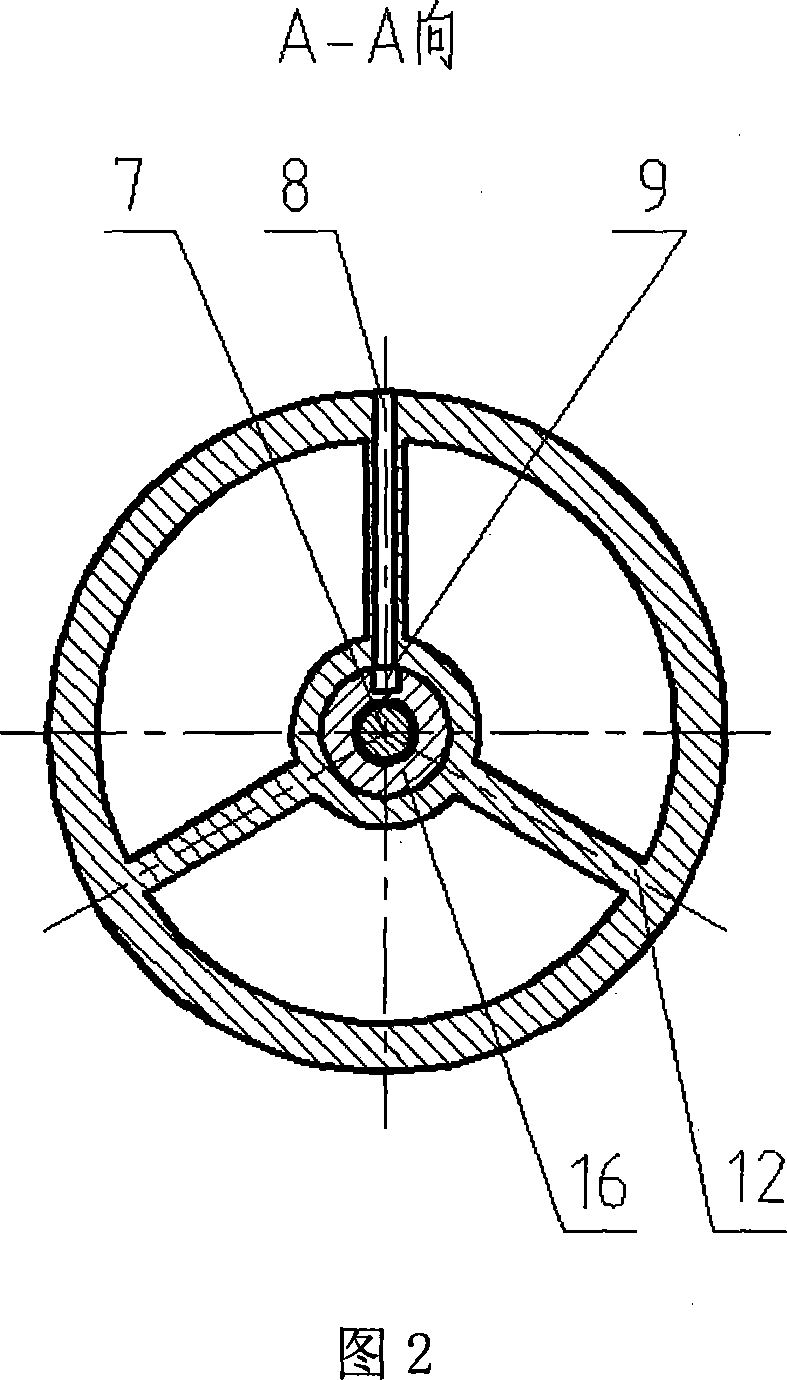

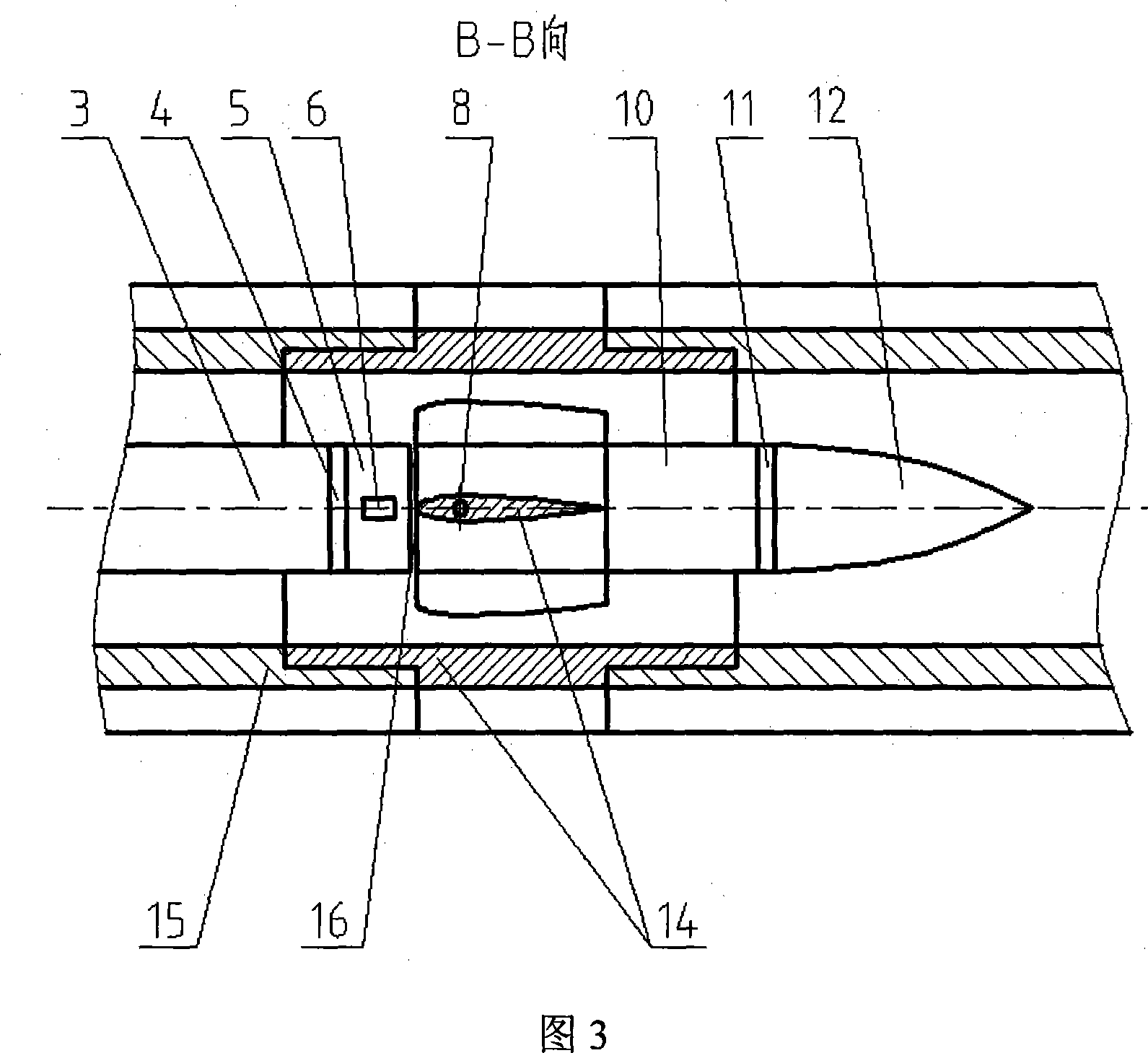

[0014] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The invention proposes a measuring device for fluid frictional resistance of a circular cross-section sample wall mainly comprising a model support unit and a resistance measuring unit. The model support unit comprises a streamlined model head 1, a support rod 16, a fixed frame 14, a front sliding support ring 2 and a rear sliding support ring 4 arranged on the support rod 16 for supporting the sample 3, and a streamlined model tail 12. The front end of the model head 1 and the support rod 16 adopts a detachable fixed connection, such as threaded or snap-fit connection, etc. The model head 1 can be designed into different shapes and sizes according to experimental requirements, so as to form the required macro flow field. The front sliding support ring 2 is slidably matched with the smooth cylindrical section at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com