Multiple moveable wall surface drag reduction device for fluid

A drag reduction device and wall technology, applied in the directions of fluid flow, hydrodynamic characteristics/hydrostatic characteristics, hull, etc., can solve the problems of limited drag reduction effect, difficulty in promotion, and high polymer price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

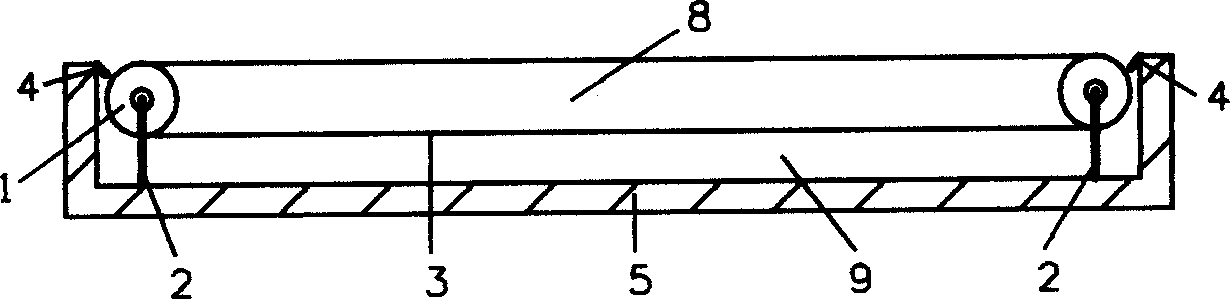

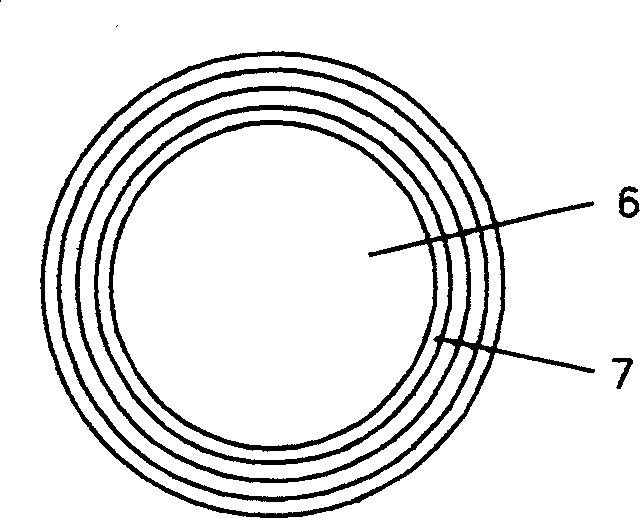

Embodiment 1

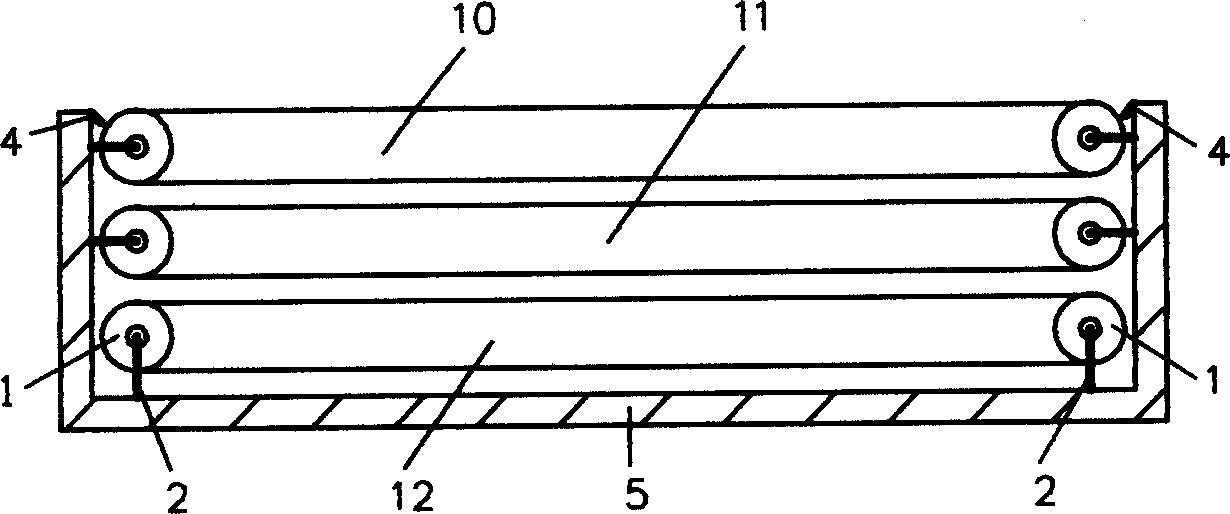

[0029] Embodiment one: Figure 6 Shown is a schematic diagram of a typical multiple movable wall fluid drag reduction device mainly used for internal flow drag reduction, in which the chamber 1 of the main movable wall system is covered with a subordinate movable wall system, and the chamber 1 of the subordinate system is located again. There is a sub-subordinate movable wall system, the brackets of which are interconnected and fixed on the shell, a subordinate movable wall system is arranged at the chamber 2 of the main movable wall system, and chamber 1 and chamber 2 of the subordinate system are respectively set There is a sub-subordinate movable wall system, each movable wall system is composed of movable wall, rotating drum and bracket, each space in the whole device is filled with lubricating fluid, and the movable wall is laminated by multiple single-layer movable walls, the specific weight The number depends on need. The filling fluid can also be determined according ...

Embodiment 2

[0030] Embodiment two: Figure 7 Shown is a typical installation schematic diagram of a multiple movable wall fluid drag reduction device mainly used for outflow drag reduction. The combination method is that two main movable wall systems are juxtaposed, and the four drums of one of the main movable wall systems are installed with the bracket. On the four vertices of the drag-reducing object, the main movable wall will be surrounded by the drag-reducing object, while another main movable wall system is installed on one side. From the figure, we can see the return of the movable wall of the two main movable wall systems The sides are adjacent, because their motion directions are consistent and their speeds are roughly equal, so all the subordinate movable wall systems of the two main movable wall systems at the position of the chamber 2 can be saved. The installation method of this embodiment is especially suitable for drag reduction of slender objects moving in fluids, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com