Device for testing fluid friction resistance

A kind of friction resistance, test device technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in more detail below in conjunction with accompanying drawing example:

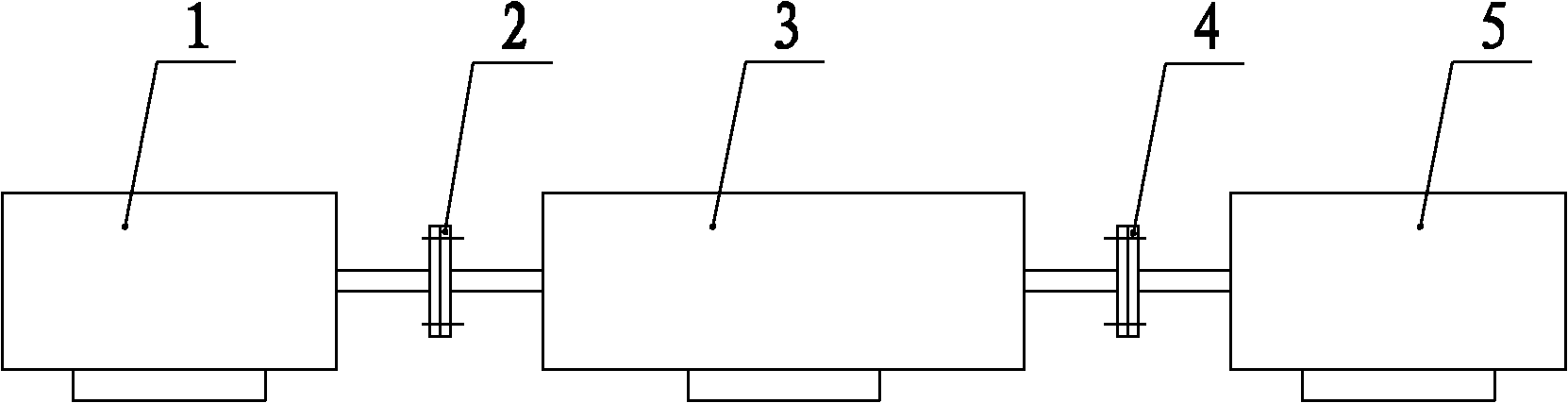

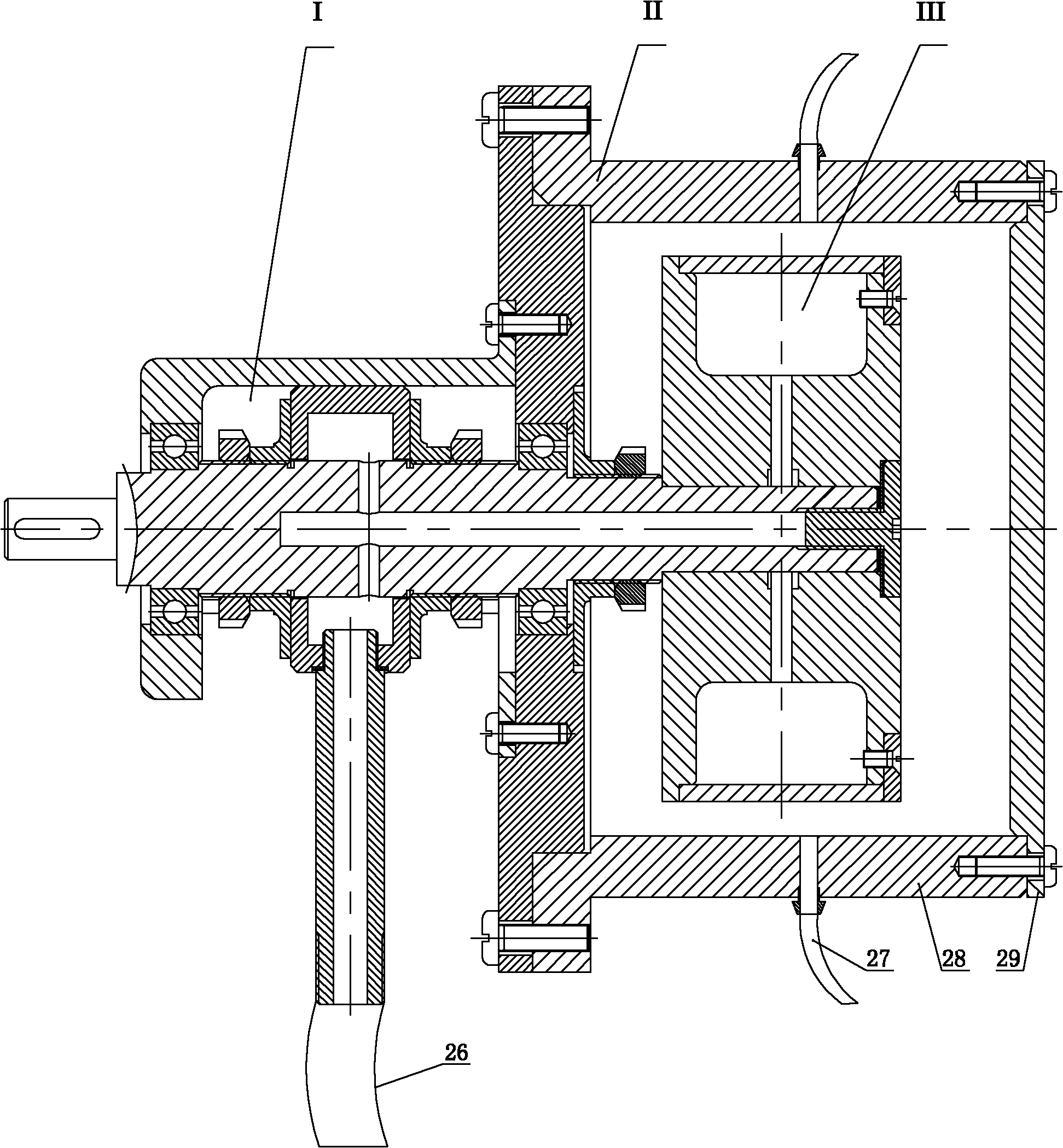

[0030] to combine figure 1 , 2 and 3, the present invention is mainly composed of a motor 1, a shaft coupling 24, a torque signal coupler 3, and a load 5. The motor 1 is brought to the torque signal coupler 3 through the shaft coupling 2, and the torque signal coupler 3 drives the load 5 to run through the shaft coupling 4. The load 5 mainly includes three parts, the water distribution link part I, the end cover sealing link part II, and the test sample link part III.

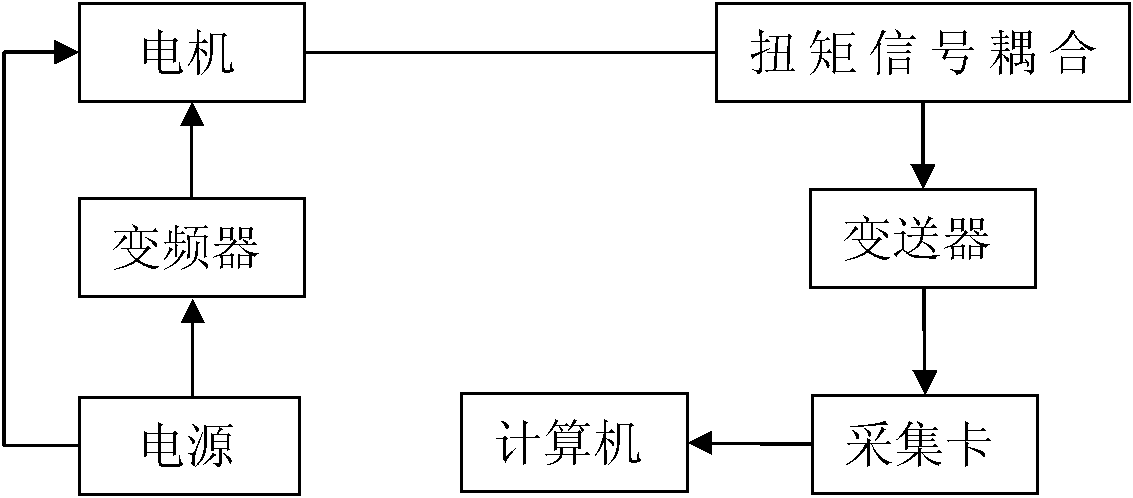

[0031] The data in the test device is collected and stored through the data acquisition system. The motor is speed regulated by a frequency converter. The torque signal coupler passes the signal through the transmitter, the acquisition card, and the computer in sequence, and reads and stores the data through the LabVIEW software. In the software interface, you can read the instantaneous value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com