Nonsmooth surface fluid friction resistance testing device and nonsmooth surface anti-drag effect evaluating method

A non-smooth surface and fluid friction technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of difficult operation, high cost, high noise, etc., and achieve the effect of simple and intuitive method, easy operation and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

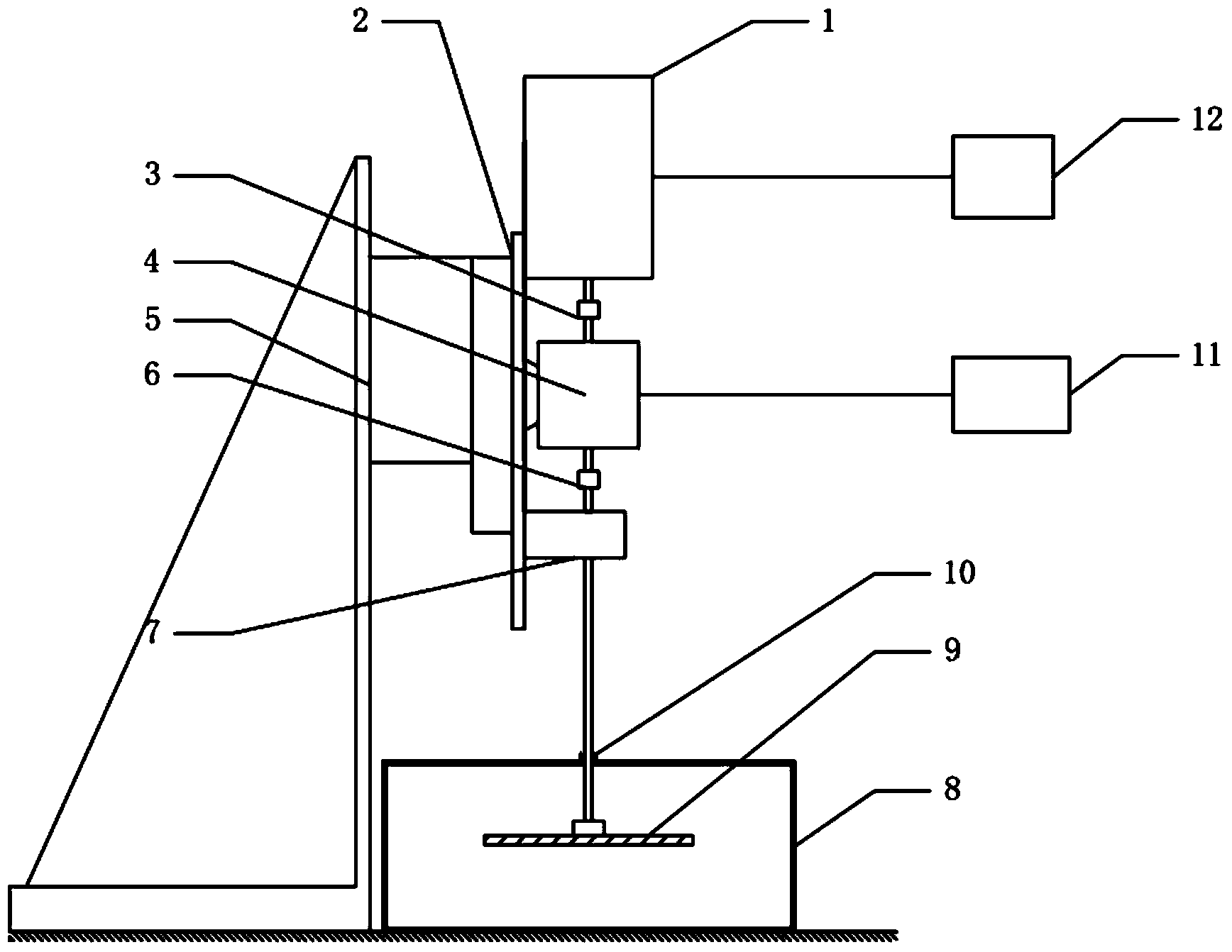

[0019] to combine figure 1 , the non-smooth surface fluid friction resistance testing device of the present invention consists of a stepping motor 1, a guide rail 2, an elastic diaphragm coupling 3, a torque signal coupler 4, a support table 5, an airtight water tank 8, a rotating disc 9, a computer 11, It consists of 12 servo hybrid stepper motor drivers. Both the stepper motor 1 and the torque signal coupler 4 are fixed on the guide rail 2 , and the guide rail 2 is installed on the supporting platform 5 . The stepping motor 1 is controlled by a servo hybrid stepping motor driver 12, the stepping motor 1 drives the torque signal coupler 4 through the elastic diaphragm coupling 3, and the torque signal coupler 4 drives the rotation through the elastic diaphragm coupling 6 Disc 9 movement.

[0020] The torque signal coupler 4 transmits the collected torque, powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com