Self-powered metro steel rail grinding wagon

A rail grinding car and power technology, which is applied in the direction of motor vehicles, railway vehicles, locomotives, etc., can solve the problems of slow speed and affect the safe operation of railway lines, so as to improve the contour, improve the running quality and passenger comfort, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

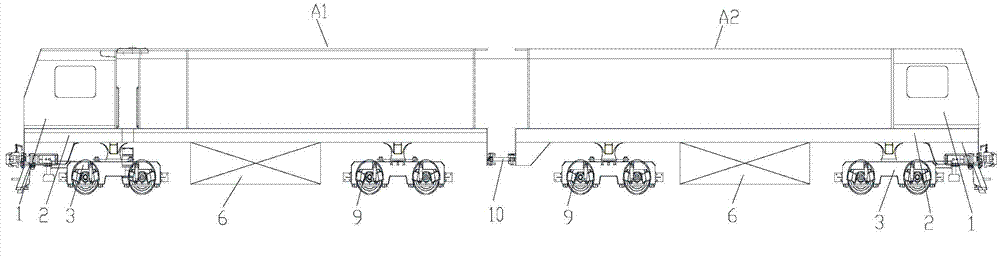

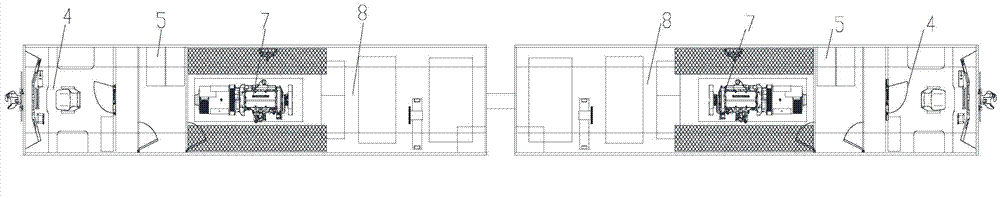

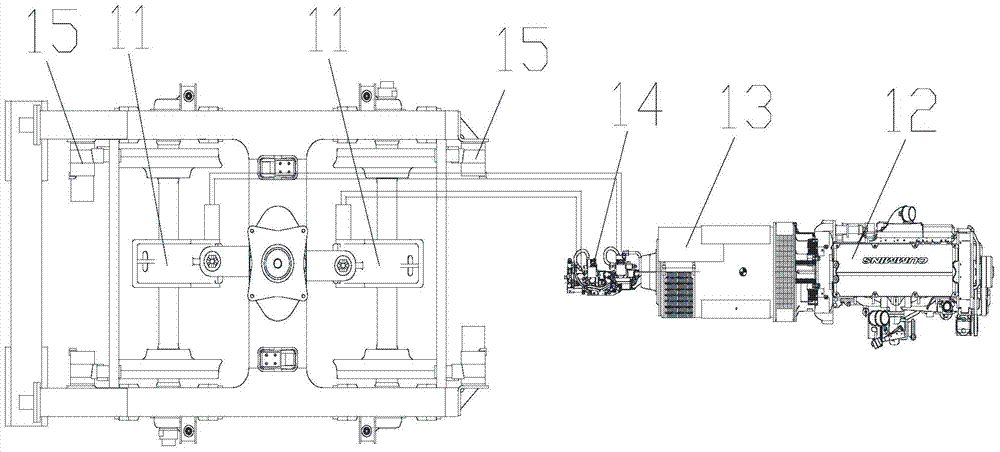

[0017] Attached below Figure 1-3 An embodiment of the present invention is described.

[0018] The subway rail grinding vehicle with its own power is composed of hydraulic transmission grinding vehicle A1 and hydraulic transmission grinding vehicle A2 connected by automatic coupler 10 to form a grinding train group, in which the hydraulic transmission grinding vehicle A1 performs rough grinding on the rail, and the hydraulic transmission grinding vehicle A2 performs rough grinding on the rail. For fine grinding, the hydraulic transmission grinding vehicle A1 and the hydraulic transmission grinding vehicle A2 have the same structure, the moving direction along the hydraulic transmission grinding vehicle A1 is forward, and the moving direction along the hydraulic transmission grinding vehicle A2 is backward. Specifically, the hydraulic transmission grinding vehicle A1 and the hydraulic transmission grinding vehicle A2 are hydraulic transmission grinding vehicles with 8 grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com