Nano crystal multiphase mixed rare earth-magnesium system hydrogen-storing alloy and its preparation method

A multi-phase mixing and hydrogen storage alloy technology, applied in the field of hydrogen storage materials, can solve the problems of difficulty in being extended to practical applications, low dehydrogenation pressure platform, difficult mass production, etc., and achieves good cycle stability, low cost, easy to use. activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare Ml 0.98 Mg 0.02 Ni 4 Hydrogen storage alloy powder 10kg. The weight percent composition of mixed rare earth Ml is selected as La40%, Nd41%, Ce5%, Pr13%, and the rest are other rare earth elements and impurities. Magnesium is a bulk metal with a purity of 99%, and nickel is an electrolytic nickel with a purity of 99.99%. Brush off the oxide layer on the surface of the metal raw material, wash it, dry it, weigh it according to the stoichiometric ratio, weigh 3.7 kg of mixed rare earth, 0.2 kg of metal magnesium, and 6.2 kg of metal nickel, place it in the graphite crucible of the vacuum induction furnace, and cover it. Furnace cover, evacuated to a vacuum degree of 10 -3 Pa, fill in Ar gas until the pressure reaches 0.002Mpa, adjust the power range to 35kw, control the temperature at 1200°C to melt the metal, keep warm and stir fully, and the melting time is 1 hour. During the smelting process, pay close attention to the change of the air pressure in the furn...

Embodiment 2

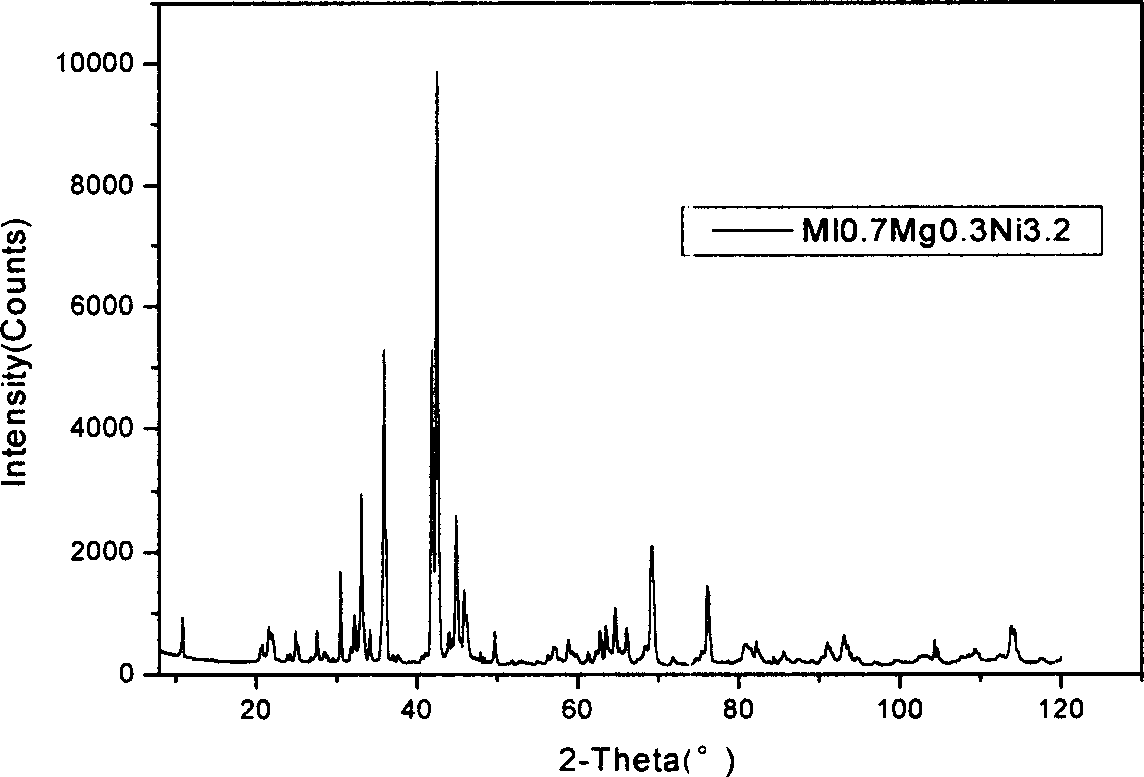

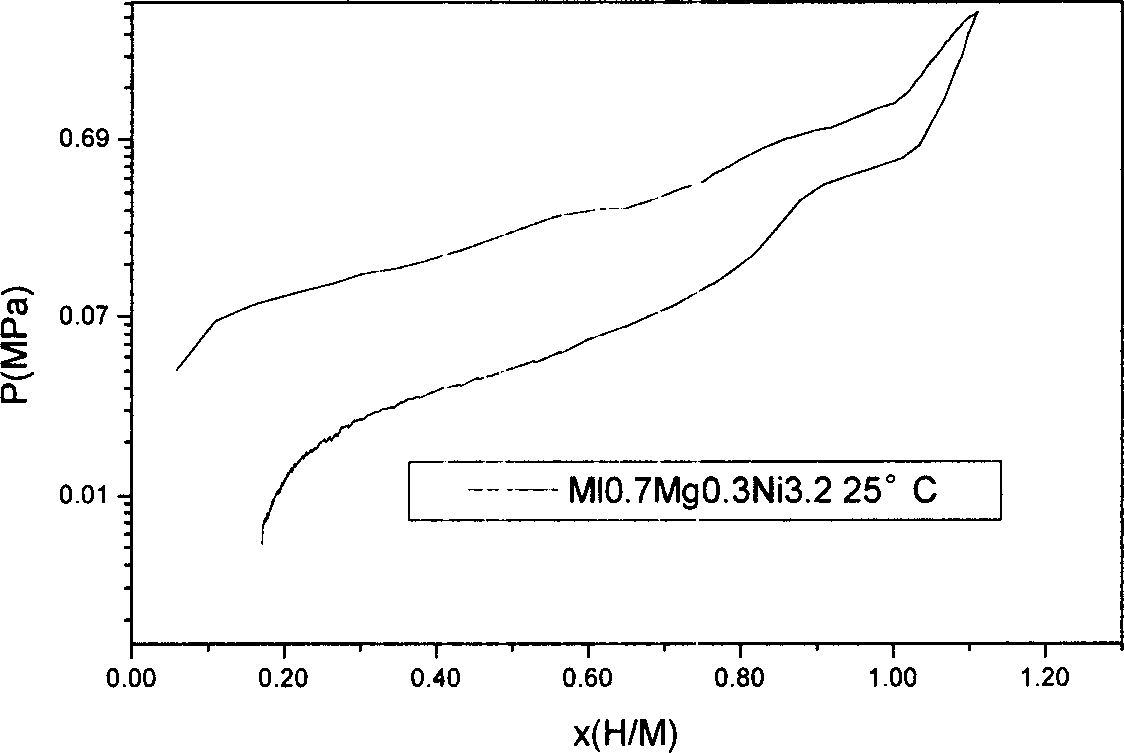

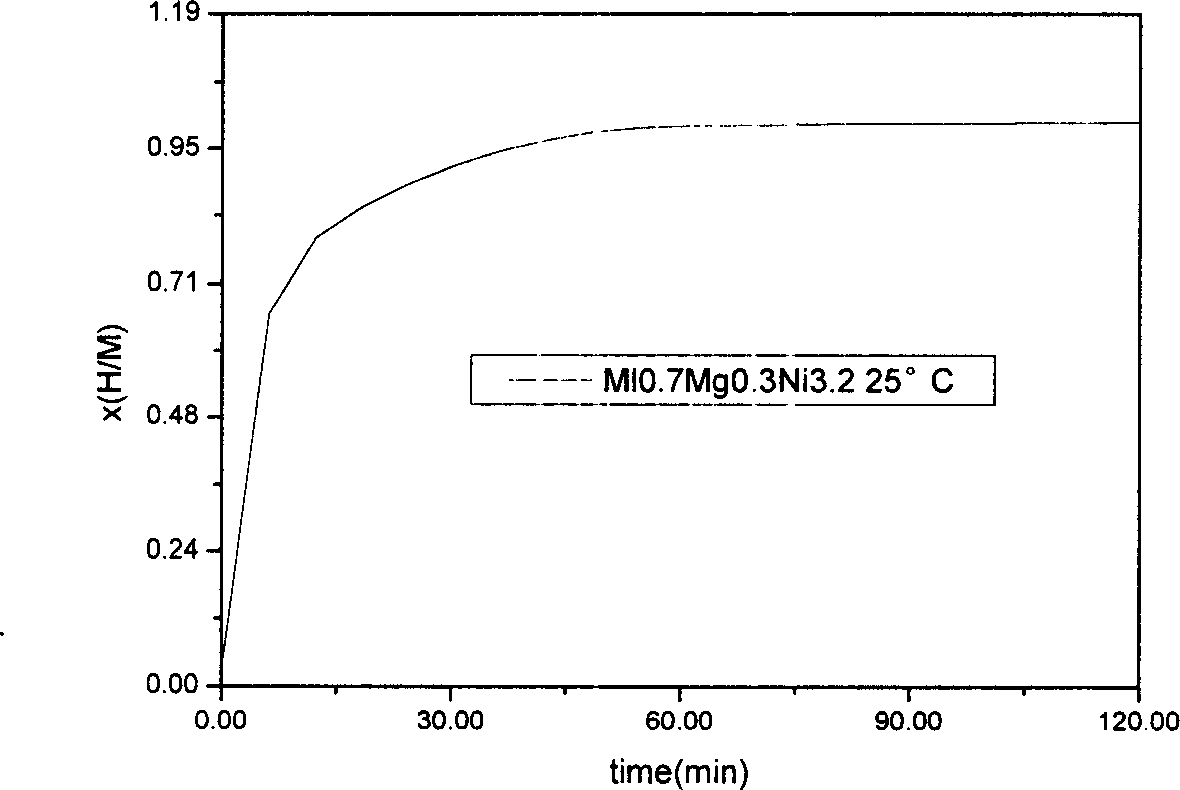

[0037] Prepare Ml 0.7 Mg 0.3 Ni 3.2 Hydrogen storage alloy powder 10kg. The weight percent composition of mixed rare earth Ml is selected as La55%, Na31%, Ce5%, Pr8%, and the rest are other rare earth elements and impurities. Magnesium is a bulk metal with a purity of 99%, and nickel is an electrolytic nickel with a purity of 99.99%. Brush off the oxide layer on the surface of the metal raw material, wash it, dry it, weigh it according to the stoichiometric ratio, weigh 3.36 kg of mixed rare earth, 2.8 kg of metal magnesium, and 6.2 kg of metal nickel, place it in the corundum crucible of the vacuum induction furnace, and cover it. Furnace cover, evacuated to a vacuum degree of 10 -2 Pa, fill it with helium until the pressure reaches 0.1Mpa, adjust the power range to 10kw for 30 minutes, 20kw for 5 minutes, and control the temperature at 1000°C to melt the metal, keep it warm and stir it fully. During the smelting process, pay close attention to the change of the air pres...

Embodiment 3

[0044] Prepare Ml 0.2 Mg 0.8 Ni 2 Hydrogen storage alloy powder 10kg. The weight percentage composition of mixed rare earth Ml is selected as La81%, Nd8.5%, Ce4%, Pr5%, and the rest are other rare earth elements and impurities. Magnesium is a bulk metal with a purity of 99%, and nickel is an electrolytic nickel with a purity of 99.99%. Brush the metal raw materials to remove the surface oxide layer, wash and dry, weigh according to the stoichiometric ratio, weigh 1.7 kg of mixed rare earth, 1.2 kg of metal magnesium, and 7.1 kg of metal nickel, place them in the graphite crucible of the vacuum induction furnace, and cover them Furnace cover, evacuated to a vacuum degree greater than 10 -3 Pa, fill in nitrogen until the pressure reaches 0.02Mpa, adjust the power range to 15kw, control the temperature at 900°C to melt the metal, keep warm and fully stir, and the melting time is 1.5 hours. During the smelting process, pay close attention to the change of the air pressure in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com