A method for preparing ternary positive electrode material using manganese-cobalt-nickel waste residue

A cathode material, manganese-cobalt-nickel technology, which is applied in the field of preparation of ternary cathode materials, can solve problems such as optimization of precursors of non-ternary cathode materials, performance optimization of non-ternary cathode materials, complex multi-stage extraction and impurity removal process, etc., to achieve The process is simple and feasible, the production cost is reduced, and the ion conductivity is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

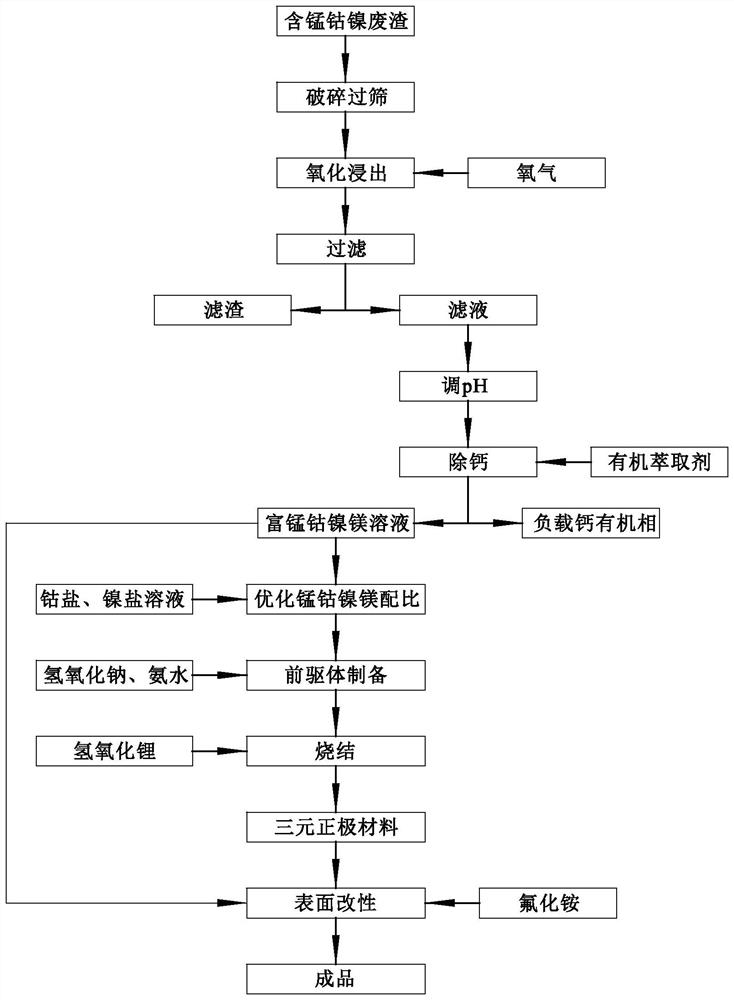

Method used

Image

Examples

preparation example Construction

[0048] (6) Preparation of ternary cathode material: Mix magnesium ion-doped manganese-cobalt-nickel ternary cathode material precursor and lithium hydroxide in a certain mass ratio, and then sinter at high temperature to obtain Li(N i0.6 Co 0.2 Mn 0.2 ) 0.99 Mg 0.01 O 2 Ternary positive electrode material; step (6), the sintering temperature is 650-900° C., the sintering time is 10h, and the amount of lithium hydroxide is 1%-10% of the theoretical excess mass of lithium hydroxide.

[0049] (7) Surface modification: disperse the ternary positive electrode material in water, and use the manganese-rich cobalt-nickel-magnesium solution and ammonium fluoride after decalcification in step (3) as modifiers to disperse the ternary positive electrode material in a certain mass ratio. The material is subjected to surface modification, and the finished product is obtained after post-treatment after the modification; the amount of modifier added is 1-5% of the mass of the ternary posi...

Embodiment 1

[0053] 10g of manganese-cobalt-nickel waste residue was crushed and sieved to 200 mesh, mixed evenly, 90g / L of dilute sulfuric acid was added at a liquid-solid ratio of 10:1, 0.1Mpa of oxygen was introduced, heated to 90°C for leaching, mechanical stirring, and leaching for 180min. Measure the end point pH=3.0, filter, take the filtrate and adjust pH=0.5 with dilute sulfuric acid, mix with volume fraction 30% P204+70% sulfonated kerosene according to the ratio O / A=1:1, and then add sodium hydroxide for saponification, The saponification rate of the extractant is 20%, the extraction is performed for 10 minutes, and then the liquid is separated in a separating funnel to obtain a manganese-rich, cobalt-rich, nickel-magnesium solution after decalcification. Manganese solution, adjust the molar ratio of nickel, cobalt, manganese and magnesium ions in the solution to 0.6:0.2:0.2:0.01, and add 1mol / L sodium hydroxide solution and 10% ammonia solution by volume at the same time to main...

Embodiment 2

[0055] 10g of manganese-cobalt-nickel waste residue was crushed and sieved to 200 mesh, mixed evenly, 100g / L of dilute sulfuric acid was added at a liquid-solid ratio of 9:1, 0.2Mpa of oxygen was introduced, heated to 80°C for leaching, mechanically stirred, and leached for 180min. Measure the end point pH=3.0, filter, take the filtrate and adjust pH=0.5 with dilute sulfuric acid, mix with volume fraction 30% P204+70% sulfonated kerosene according to the ratio O / A=1:1, add sodium hydroxide for saponification, wherein The saponification rate of the extractant is 20%, extraction is performed for 10 minutes, and then the liquid is separated in a separating funnel to obtain a manganese-cobalt-nickel-magnesium solution rich in manganese, cobalt, nickel, and magnesium after decalcification. , adjust the molar ratio of nickel, cobalt, manganese, and magnesium in the solution to 0.5:0.3:0.2:0.02, add 2mol / L sodium hydroxide solution and 15% ammonia solution by volume at the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com