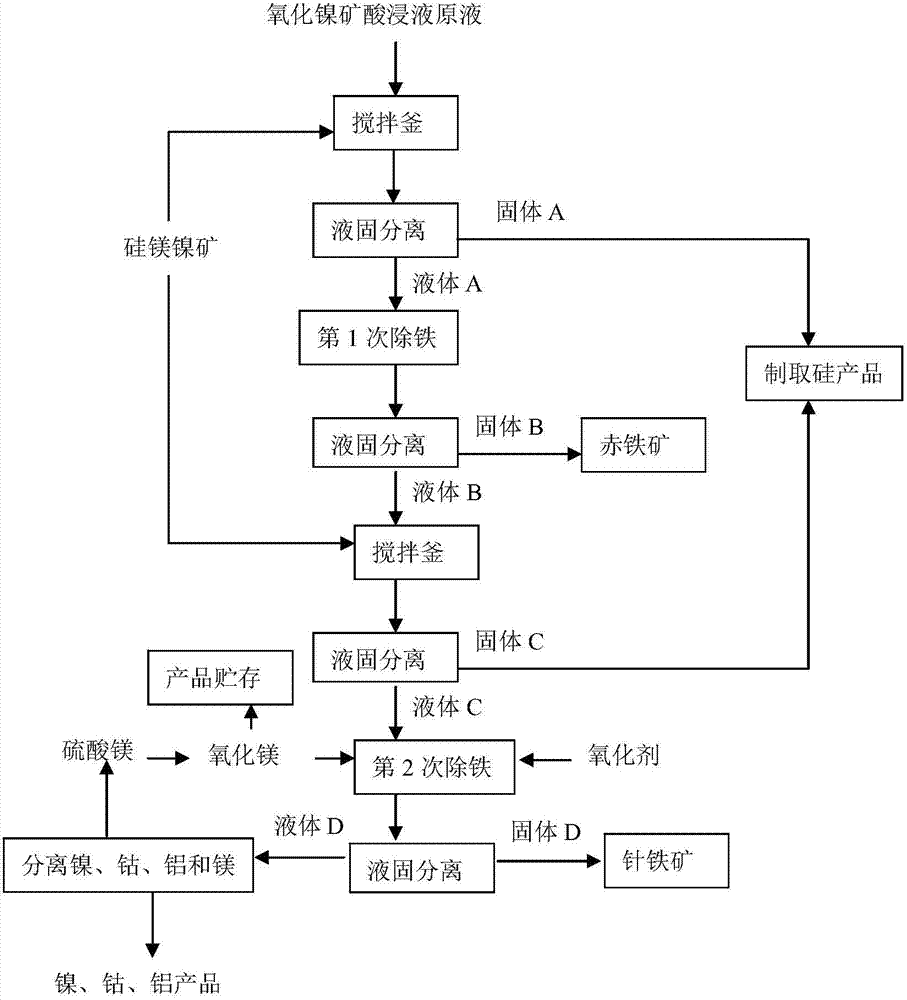

Nickel oxide ore acid leaching solution two-step iron removal method

A technology for nickel oxide ore and acid leaching solution, applied in the field of nickel ore smelting, can solve problems such as complicated production operation, and achieve the effects of eliminating separation process, improving crystallinity and improving filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Fe in the stock solution of sulfuric acid leaching solution of nickel oxide ore 3+ , Fe 2+ , Ni 2+ ,Co 2+ , Mg 2+ , Al 3+ The concentrations are 30.4g / L, 0.5g / L, 1.05g / L, 0.095g / L, 4.3g / L, 1.89g / L, the pH value of the stock solution is 0.38, and the solid content is 30% in the stock solution (wt%) of Simagnesium-nickel ore aqueous slurry (wherein, Fe, Ni, Co, Mg, the content of Al are respectively 4.8%, 1.9%, 0.04%, 24.1%, 3.7% in Simagnesia-nickel ore, Simagnesium-nickel ore The amount of ore slurry added is 2.5 times the volume of the original solution), stirred and reacted at 90°C for 1 hour (at this time, the silicon-magnesium-nickel ore slurry is completely dissolved), and liquid-solid separation is carried out to obtain solid A and liquid A;

[0033] (2) Warm up the liquid A to 160°C, stir and react for 1.5h, and separate the liquid and solid to obtain solid B and liquid B, collect and dry the solid B to obtain the hematite product;

[0034] (3) Add the ...

Embodiment 2

[0040] (1) Fe in the stock solution of sulfuric acid leaching solution of nickel oxide ore 3+ , Fe 2+ , Ni 2+ ,Co 2+ , Mg 2+ , Al 3+ The concentrations are 42.4g / L, 2.5g / L, 1.24g / L, 0.15g / L, 3.3g / L, 1.1g / L, the pH value of the stock solution is -0.03, and the solid content is 20 % (wt %) of Simagnesium ore aqueous ore slurry (wherein, Fe, Ni, Co, Mg, the content of Al are respectively 3.2%, 1.19%, 0.05%, 19.1%, 4.9% in Simagnesia nickel ore, Simagnesium The amount of nickel ore slurry added is 3 times the volume of the original solution), stirred and reacted at 100°C for 0.5h (at this time, the silicon-magnesium-nickel ore slurry is completely dissolved), and liquid-solid separation is carried out to obtain solid A and liquid A;

[0041] (2) Warm up the liquid A to 140°C, stir and react for 2 hours, and separate the liquid and solid to obtain solid B and liquid B, collect and dry the solid B to obtain the hematite product;

[0042] (3) In liquid B, add magnesia ore pulp ...

Embodiment 3

[0047] (1) Fe in the stock solution of sulfuric acid leaching solution of nickel oxide ore 3+ , Fe 2+ , Ni 2+ ,Co 2+ , Mg 2+ , Al 3+ The concentrations are 19.4g / L, 3.1g / L, 1.0g / L, 0.11g / L, 8.3g / L, 2.1g / L, the pH value of the stock solution is 0.73, and the solid content is 40% in the stock solution (wt%) of Simagnesium-nickel ore aqueous slurry (wherein, Fe, Ni, Co, Mg, the content of Al are respectively 1.5%, 1.09%, 0.02%, 13.4%, 5.9% in Simagnesia-nickel ore, Simagnesium-nickel ore The amount of ore pulp added is 1.5 times the volume of the original liquid), stirred and reacted at 60°C for 2 hours (at this time, the silicon-magnesium-nickel ore pulp is completely dissolved), and liquid-solid separation is carried out to obtain solid A and liquid A;

[0048] (2) Warm up the liquid A to 130°C, stir and react for 3 hours, and separate the liquid and solid to obtain solid B and liquid B, collect and dry the solid B to obtain the hematite product;

[0049] (3) Add the Sibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com