Gold and silver beneficiation agent, and preparation method and application thereof

A mineral processing method and mineral processing agent technology, applied in the field of gold and silver mineral processing agents, can solve the problems of high production cost, complex production process, high toxicity of gold and silver mineral processing agents, etc., and achieve the effect of low cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

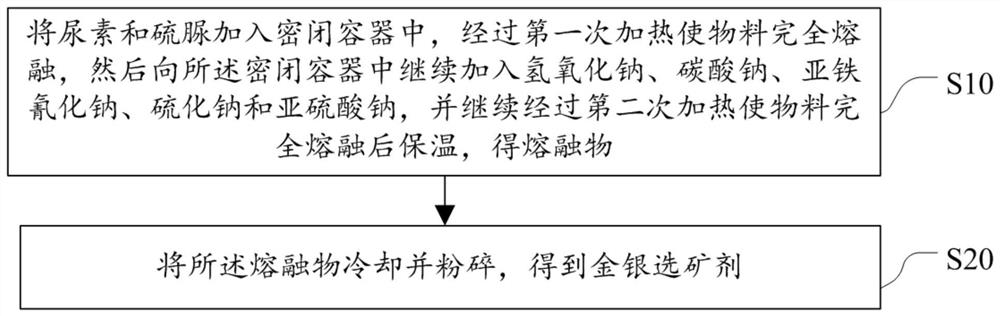

[0038] The present invention further proposes a kind of preparation method of gold-silver beneficiation agent as mentioned above, figure 1 For the schematic flow diagram of an embodiment of the preparation method of the gold and silver mineral processing agent proposed by the present invention, please refer to figure 1 , the preparation method of described gold-silver beneficiation agent comprises the following steps:

[0039] S10, add urea and thiourea into the airtight container, heat the material for the first time to completely melt, then continue to add sodium hydroxide, sodium carbonate, sodium ferrocyanide, sodium sulfide and sodium sulfite into the airtight container, and Continue to heat for the second time to make the material completely melt and then keep it warm to obtain the melt.

[0040] Preferably, in this step, the heating temperature of the first heating is 180°C-200°C. At this temperature, urea and thiourea rapidly become molten.

[0041] The heating temp...

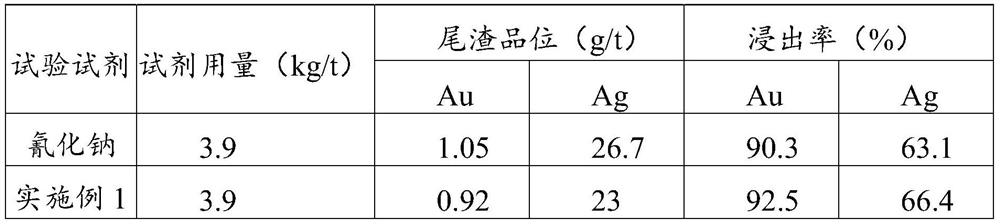

Embodiment 1

[0058] According to parts by weight, take 15 parts of urea and 8 parts of thiourea, mix them evenly, heat to 200°C, after completely melting, add 5 parts of sodium ferrocyanide, 6 parts of sodium hydroxide, 10 parts of sodium carbonate, and 2 parts of sodium sulfide 1. 2 parts of sodium sulfite, rapidly heated to 900°C, kept for 3 hours, poured out the melted matter, cooled and pulverized to obtain gold and silver extractant. NH produced during the preparation 3 , CO 2 , SO 2 After the exhaust gas is cooled, absorb it with sodium chloride solution.

Embodiment 2

[0060] According to parts by weight, take 20 parts of urea and 12 parts of thiourea and mix evenly, heat to 180°C, after melting completely, add 5 parts of sodium ferrocyanide, 8 parts of sodium hydroxide, 15 parts of sodium carbonate, and 2 parts of sodium sulfide 1. 2 parts of sodium sulfite, rapidly heated to 900°C, kept for 3 hours, poured out the melted matter, cooled and pulverized to obtain gold and silver extractant. NH produced during the preparation 3 , CO 2 , SO 2 After the exhaust gas is cooled, absorb it with sodium chloride solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com