Waste storage battery dismantling processing technology

A technology of waste battery and processing technology, which is applied in the direction of battery recycling, improvement of process efficiency, recycling of waste collectors, etc., and can solve problems such as arsenic secondary pollution, waste of resources, environment, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A dismantling process based on waste storage batteries, characterized in that it comprises the following steps:

[0032] Step 1. Soak the waste battery in aqueous sodium hydroxide solution, discharge for 1 hour, and then fix and disassemble the shell of the discharged waste battery to obtain the anode electrode grid, anode slime, and cathode electrode grid;

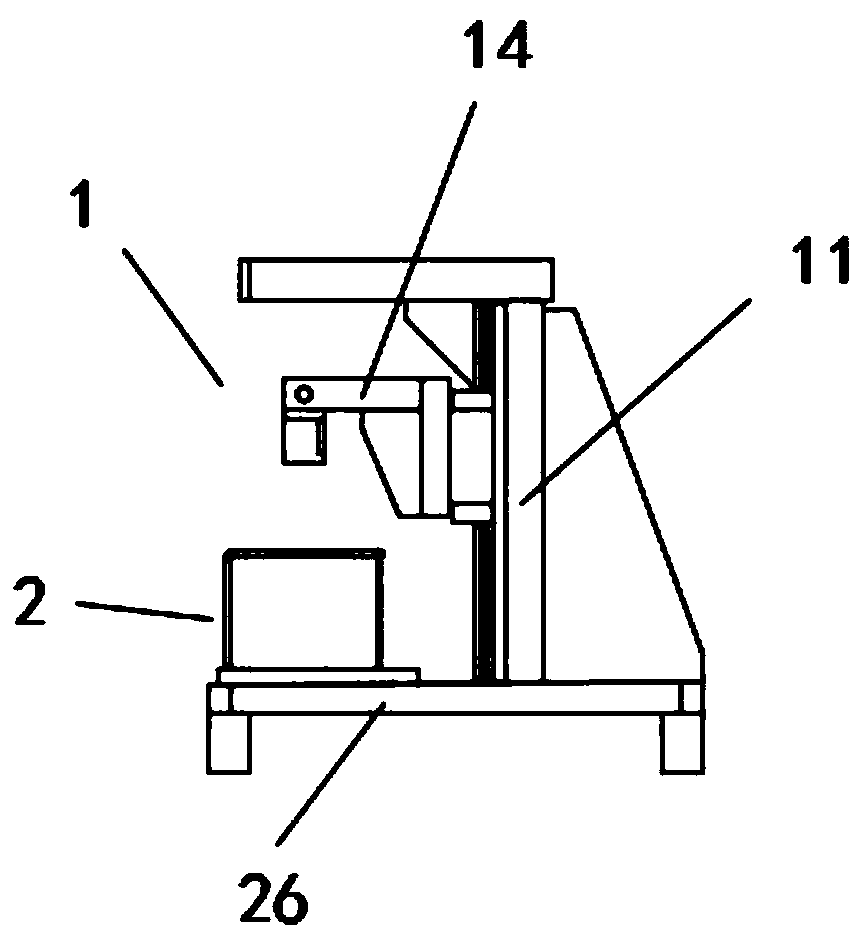

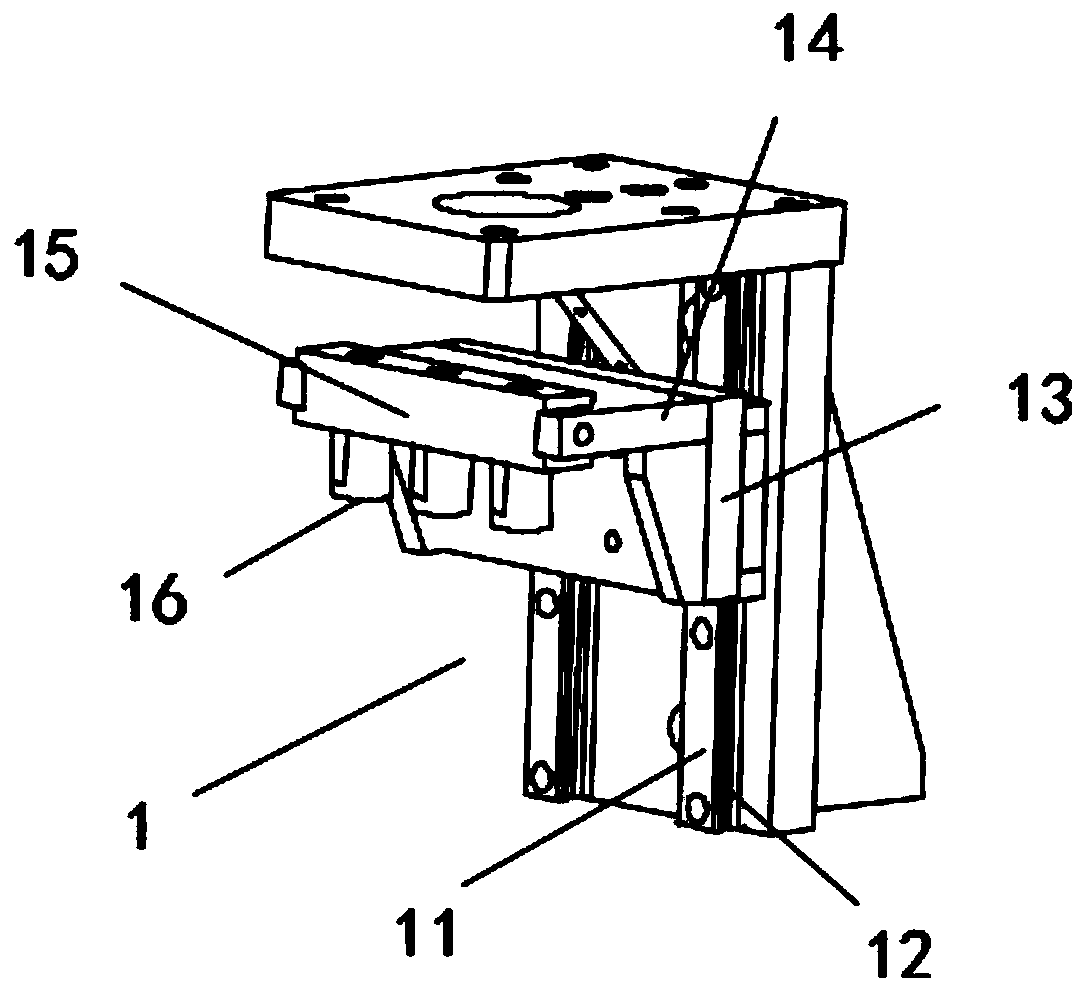

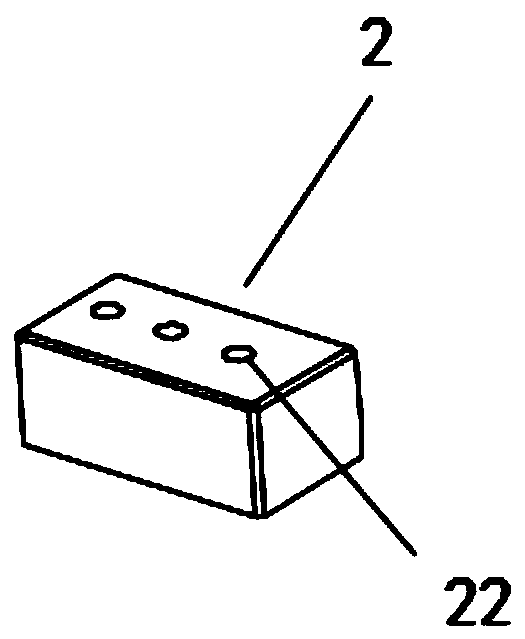

[0033] When the fixing is disassembled, it is fixed by a fixing device, and the fixing device is as Figure 1-3 As shown, the fixing device includes an upper fixing mechanism 1 and a lower fixing mechanism 2, and the upper fixing mechanism 1 is installed above the lower fixing mechanism 2;

[0034] Such as Figure 1-2As shown, the upper fixing mechanism 1 includes a vertical fixing rod 11, a sliding groove 12, a connecting plate 13, a supporting plate 14, a first fixing block 15 and a first limiting groove 16, and the vertical fixing rod 11 is provided with a sliding Groove 12, connecting plate 13 is installed on...

Embodiment 2

[0041] A dismantling process based on waste storage batteries, characterized in that it comprises the following steps:

[0042] Step 1. Soak the waste battery in aqueous sodium hydroxide solution, discharge for 2 hours, and then fix and disassemble the shell of the discharged waste battery to obtain the anode electrode grid, anode slime, and cathode electrode grid;

[0043] Step 2. Mix the anode slime and aqueous sodium hydroxide solution according to the ratio of solid-to-liquid ratio of 1:4, raise the temperature to 75°C, stir for 2 hours at a speed of 140r / min, control the pressure at 0.1MPa during the stirring process, add 10% super Hydrogen peroxide aqueous solution, control the liquid-solid ratio of 10% hydrogen peroxide aqueous solution and anode slime to 1:2, continue to stir for 30 minutes, filter, collect the filtrate, cool, and wash the filter residue three times with 10% dilute hydrochloric acid solution;

[0044] Step 3: Add the anode electrode grid and the cathod...

Embodiment 3

[0047] A dismantling process based on waste storage batteries, characterized in that it comprises the following steps:

[0048] Step 1. Soak the waste battery in aqueous sodium hydroxide solution, discharge for 2 hours, and then fix and disassemble the shell of the discharged waste battery to obtain the anode electrode grid, anode slime, and cathode electrode grid;

[0049] Step 2. Mix the anode slime and sodium hydroxide aqueous solution according to the ratio of solid to liquid ratio of 1:5, raise the temperature to 75°C, and stir for 2 hours at a speed of 140r / min. During the stirring process, the pressure is controlled at 0.2MPa, and 10% super Hydrogen peroxide aqueous solution, control the liquid-solid ratio of 10% hydrogen peroxide aqueous solution and anode slime to 1:1, continue to stir for 30 minutes, filter, collect the filtrate, cool, and wash the filter residue three times with 10% dilute hydrochloric acid solution;

[0050] Step 3: Add the anode electrode grid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com