Method for separating and purifying tellurium from cuprous telluride slag through vacuum distillation

A technology of cuprous telluride slag and cuprous telluride, which is applied in the field of metallurgy, can solve the problems of low direct yield and long process flow of cuprous telluride slag treatment process, and achieve directional separation and purification of valuable metals, process flow Short, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

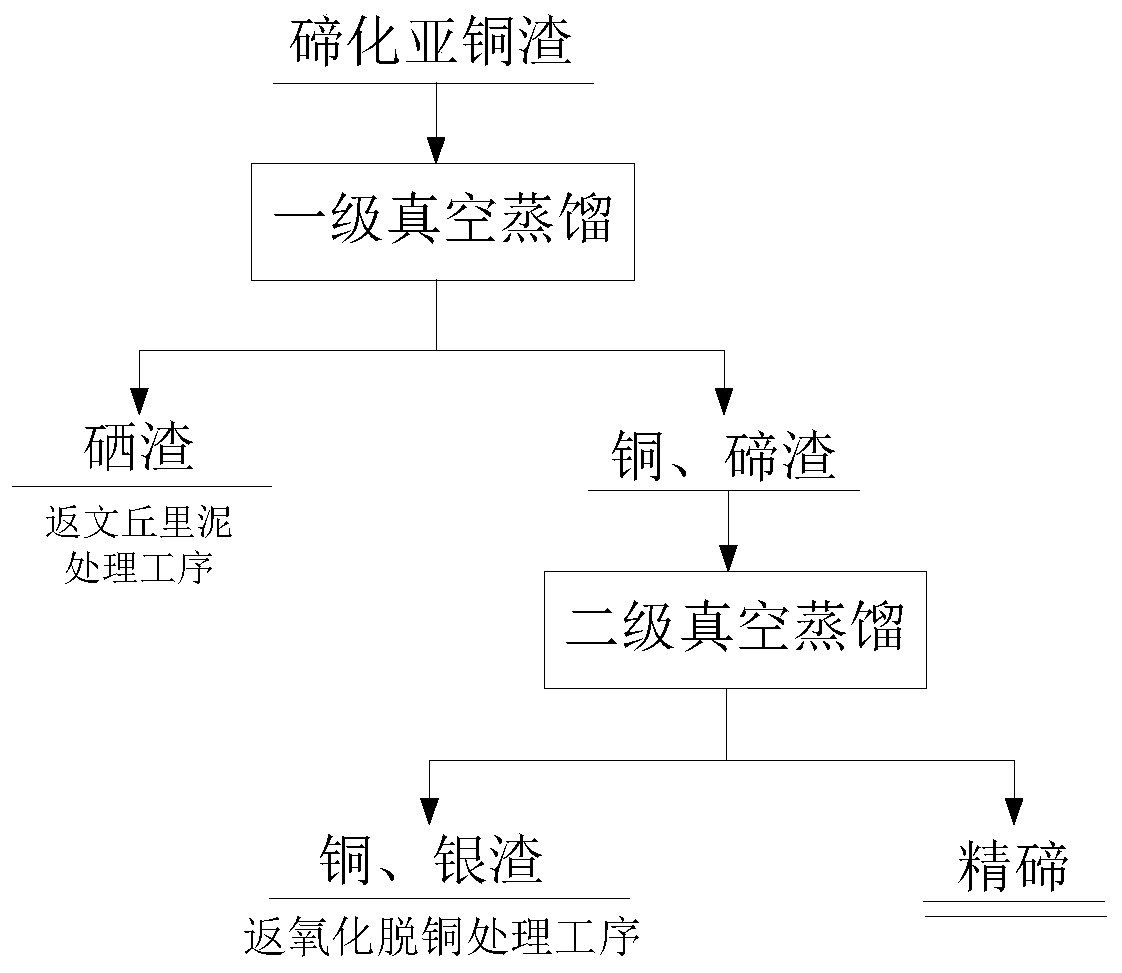

[0029] This embodiment provides a method for separating and purifying tellurium from cuprous telluride slag by vacuum distillation, as shown in Figure 1, specifically:

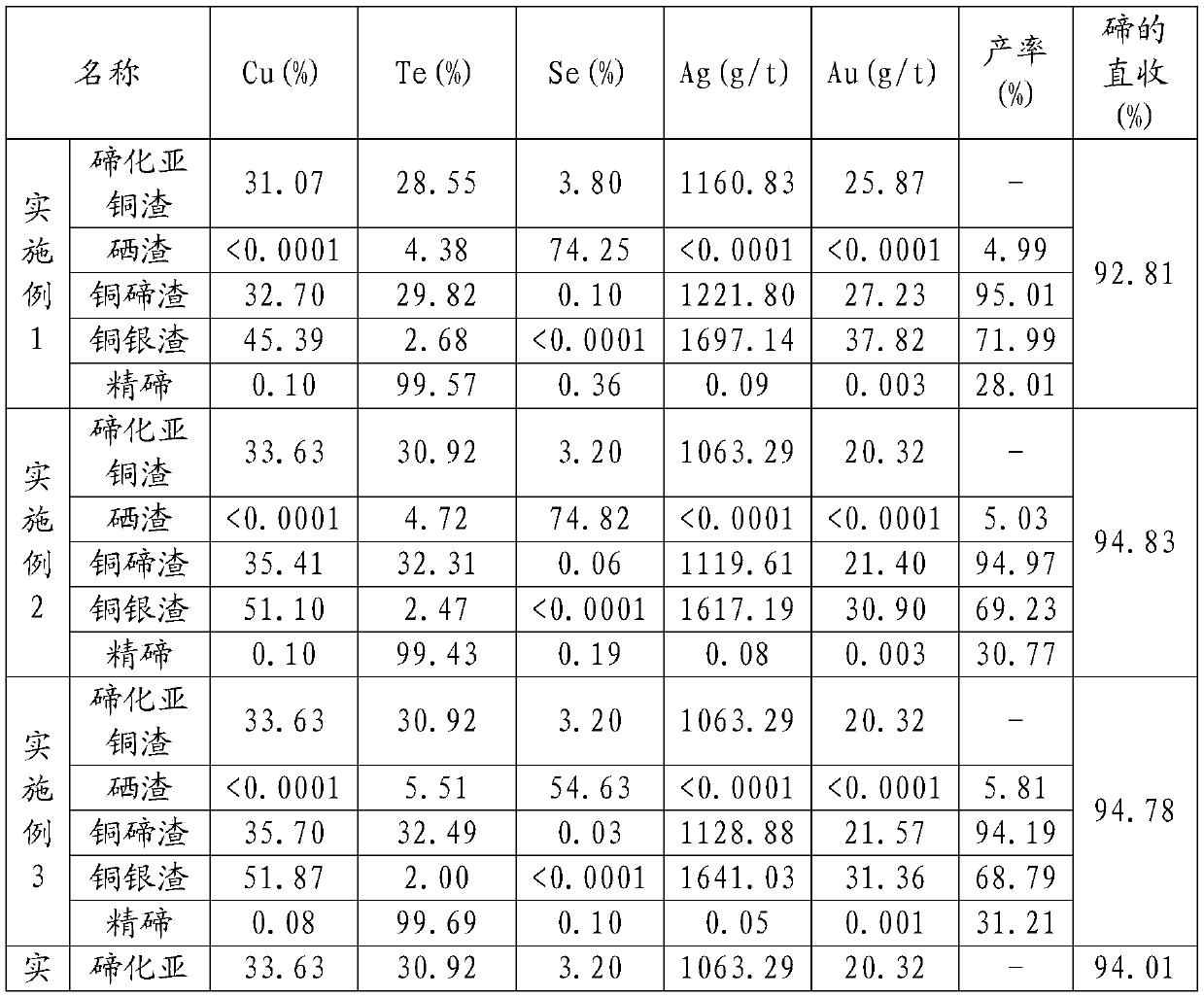

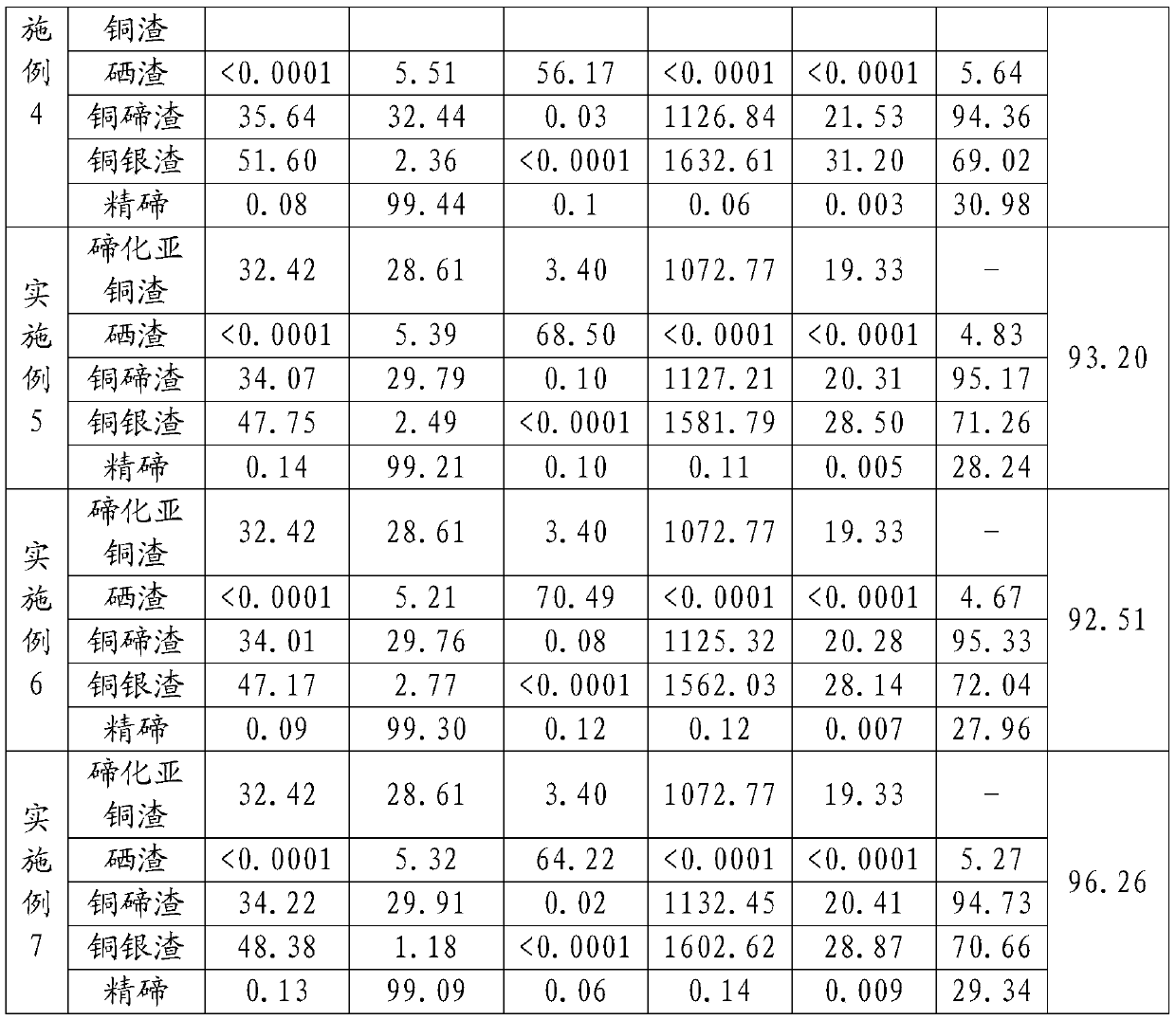

[0030] Take 10kg of cuprous telluride slag containing 31.07% copper, 28.55% tellurium, 3.8% selenium, 1160.83g / t silver, and 25.87g / t gold, and place it in a vacuum distillation furnace at a vacuum degree of 40-60Pa and a temperature of Under the condition of 400°C, vacuum distillation for 3 hours produces selenium slag and copper tellurium slag. Put the copper-tellurium slag in a vacuum distillation furnace, and vacuum distill it again for 3 hours under the conditions of a vacuum degree of 30-50Pa and a temperature of 900°C to produce refined tellurium products and copper-silver slag.

[0031] The selenium slag is returned to the Venturi mud treatment process, and is reduced by sodium sulfite after two-stage countercurrent alkali leaching to obtain crude selenium products. The copper and silver slag is retur...

Embodiment 2

[0033] This embodiment provides a method for separating and purifying tellurium by vacuum distillation of cuprous telluride slag, specifically:

[0034] Take 10kg of cuprous telluride slag containing 33.63% copper, 29.92% tellurium, 3.2% selenium, 1063.29g / t silver, and 20.32g / t gold, and place it in a vacuum distillation furnace at a vacuum degree of 40-60Pa and a temperature of Under the condition of 420°C, vacuum distillation for 3 hours produces selenium slag and copper tellurium slag. Place the copper tellurium slag in a vacuum distillation furnace, vacuum distillation for 3 hours under the condition of vacuum degree of 30-50Pa and temperature of 920°C to produce refined tellurium product and copper silver slag.

Embodiment 3

[0036] This embodiment provides a method for separating and purifying tellurium by vacuum distillation of cuprous telluride slag, specifically:

[0037] Take 10kg of cuprous telluride slag containing 33.63% copper, 29.92% tellurium, 3.2% selenium, 1063.29g / t silver, and 20.32g / t gold, and place it in a vacuum distillation furnace at a vacuum degree of 40-60Pa and a temperature of Under the condition of 470°C, vacuum distillation for 3 hours produces selenium slag and copper tellurium slag. Place the copper tellurium slag in a vacuum distillation furnace, vacuum distillation for 3 hours under the conditions of vacuum degree 30-50Pa and temperature 930°C to produce refined tellurium product and copper silver slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com