Method for leaching gold and silver out of kustelite wrapped by manganese under normal pressure and temperature

A gold-silver, normal pressure technology, applied in the field of beneficiation of manganese-coated gold-silver ore, can solve the problems of complex process, large consumption of chemicals, high cost, etc., achieve large specific surface area, high gold and silver leaching rate, and strong reduction ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

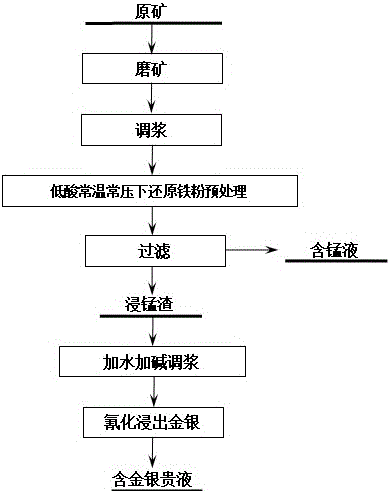

Image

Examples

Embodiment 1

[0027] The original ore is a manganese-silver mine in Yunnan, China.

[0028] S1. Grinding the raw ore to -0.074mm accounts for 80%, adding water to adjust the pulp concentration to 35%;

[0029] S2. Pretreatment: Add 30Kg / t of sulfuric acid to the grinding product according to the amount of ore (for safety, first dilute the concentrated sulfuric acid to dilute sulfuric acid with a mass concentration of 5%), add 8Kg / t according to the amount of ore Reduced iron powder, stirred at normal temperature and pressure for 3 hours to obtain the pretreated raw ore;

[0030] S3. Filtration: filter the pretreated raw ore to obtain manganese-containing filtrate and manganese leaching slag;

[0031] S4. Cyanide leaching of gold and silver from manganese leaching slag: add water to the manganese leaching slag to adjust the pulp concentration to 36%, add sodium hydroxide 500g / t, and lime 6Kg / t to adjust the slurry to a pH value of 10, based on ore weight , add sodium cyanide 1000g / t. Stir...

Embodiment 2

[0034] The original ore is a manganese silver mine in Guangxi, China.

[0035] S1. Raw ore is ground to -0.074mm, accounting for 65%, adding water to adjust the pulp concentration to 30%;

[0036] S2. Pretreatment: add 15Kg / t of sulfuric acid to the grinding product according to the amount of ore (for safety, first dilute the concentrated sulfuric acid to dilute sulfuric acid with a mass concentration of 10%), add 12Kg / t according to the amount of ore Reduced iron powder, stirred at normal temperature and pressure for 4.5 hours to obtain pretreated raw ore;

[0037] S3. Filtration: filter the pretreated raw ore to obtain manganese-containing filtrate and manganese leaching slag;

[0038] S4. Cyanide leaching of gold and silver from manganese leaching slag: add water to the manganese leaching slag to adjust the pulp concentration to 31%, add lime 8Kg / t to adjust the slurry to a pH value of 11, and add sodium cyanide 1300g / t based on the ore weight t. Stir and leach at normal...

Embodiment 3

[0041] The original ore is a manganese-silver mine in Yunnan, China.

[0042] S1. Grinding the raw ore to -0.074mm accounts for 80%, adding water to adjust the pulp concentration to 30%;

[0043] S2. Pretreatment: add 20Kg / t of sulfuric acid to the grinding product according to the amount of ore (for safety, first dilute the concentrated sulfuric acid to dilute sulfuric acid with a mass concentration of 10%), add 8Kg / t according to the amount of ore Reduced iron powder, stirred at normal temperature and pressure for 3 hours to obtain the pretreated raw ore;

[0044] S3. Filtration: filter the pretreated raw ore to obtain manganese-containing filtrate and manganese leaching slag;

[0045] S4. Cyanide leaching of gold and silver from manganese leaching slag: add water to the manganese leaching slag to adjust the pulp concentration to 36%, add sodium hydroxide 500g / t, and lime 6Kg / t to adjust the slurry to a pH value of 10, based on ore weight , add sodium cyanide 1000g / t. Sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com