Method for selectively leaching scandium and sodium from bayer red mud

A Bayer red mud and selective technology, applied in the direction of improving process efficiency, can solve the problems of non-recyclable, complex process, large acid consumption, etc., and achieve the effect of reducing consumption, cost and requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]A method for selectively leaching scandium and sodium from Bayer red mud, said method comprising the following steps:

[0035] (1) Mix Bayer red mud with concentrated sulfuric acid with a mass fraction of 65% according to the ratio of solid to liquid 1 g: 1.5 (g:ml), and use sulfuric acid to completely salinize Bayer red mud under low temperature conditions, so that red Mud minerals are converted into corresponding sulfates to obtain sulfated red mud; the salinization conditions are as follows: temperature 120 °C, holding time 20 minutes;

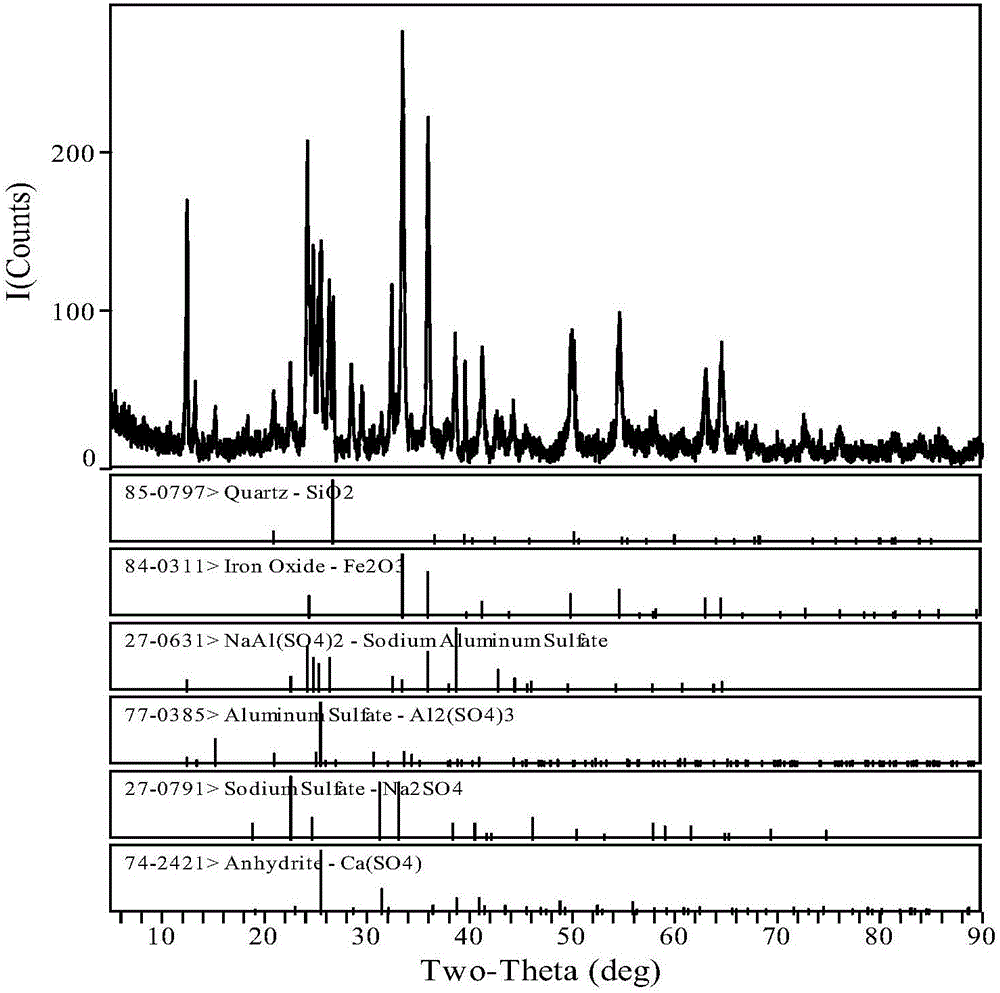

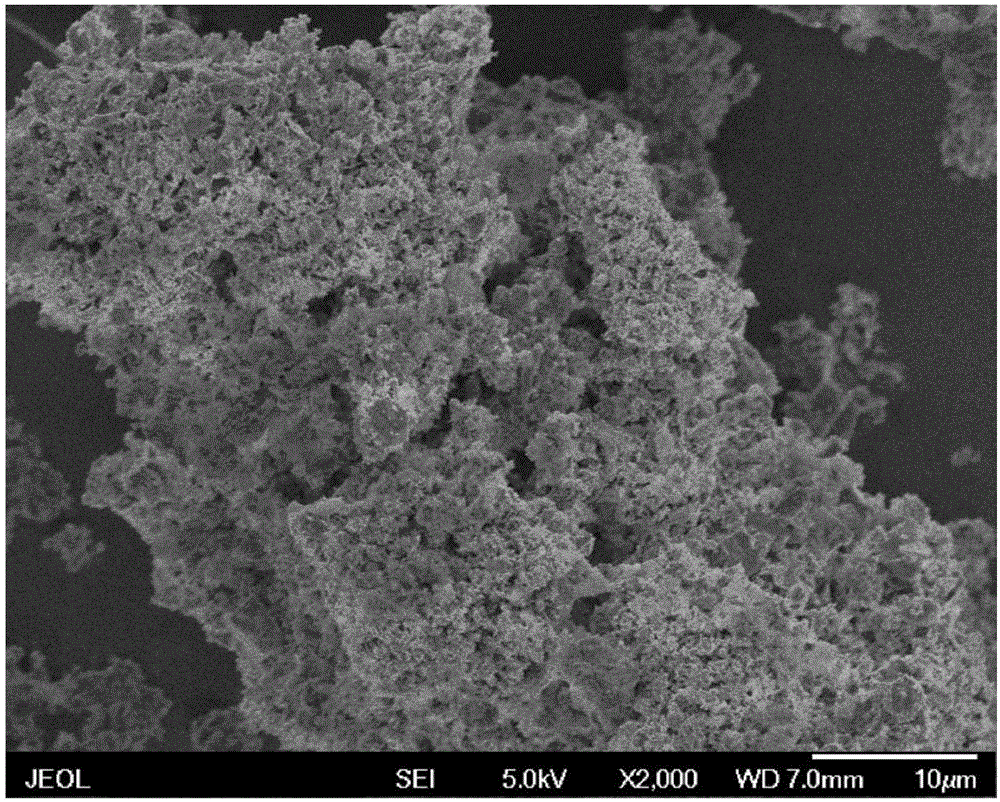

[0036] (2) Roasting the mineral salted red mud prepared in step (1) at a medium temperature, and obtaining roasted products by virtue of the different mineral decomposition temperatures of different sulfates in the sulfated red mud, and the roasted products include easy Dissolved scandium and sodium sulfate and impurity minerals that are not easily soluble; the impurity minerals include iron oxides and aluminum oxides; the conditions ...

Embodiment 2

[0041] A method for selectively leaching scandium and sodium from Bayer red mud, said method comprising the following steps:

[0042] (1) Mix Bayer red mud with concentrated sulfuric acid with a mass fraction of 75% according to the ratio of solid to liquid 1: 1.5 (g:ml), and use concentrated sulfuric acid to completely salinize Bayer red mud under low temperature conditions, so that Red mud minerals are transformed into corresponding sulfates to obtain sulfated red mud; the salinization conditions are as follows: temperature 150 °C, holding time 20 minutes;

[0043] (2) Roasting the mineral salted red mud prepared in step (1) at a medium temperature, and obtaining roasted products by virtue of the different mineral decomposition temperatures of different sulfates in the sulfated red mud, and the roasted products include easy Dissolved scandium and sodium sulfate and impurity minerals that are not easily soluble; the impurity minerals include iron oxides and aluminum oxides; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com