A method for preparing high-purity manganese sulfate from electrolytic manganese sulfide slag

A technology of sulfide slag and electrolytic manganese, applied in the direction of improving process efficiency, etc., can solve the problems of cobalt soap pre-liquid waste and cumbersome process, etc., achieve the effects of reducing acid consumption, simple and feasible process, and improving leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

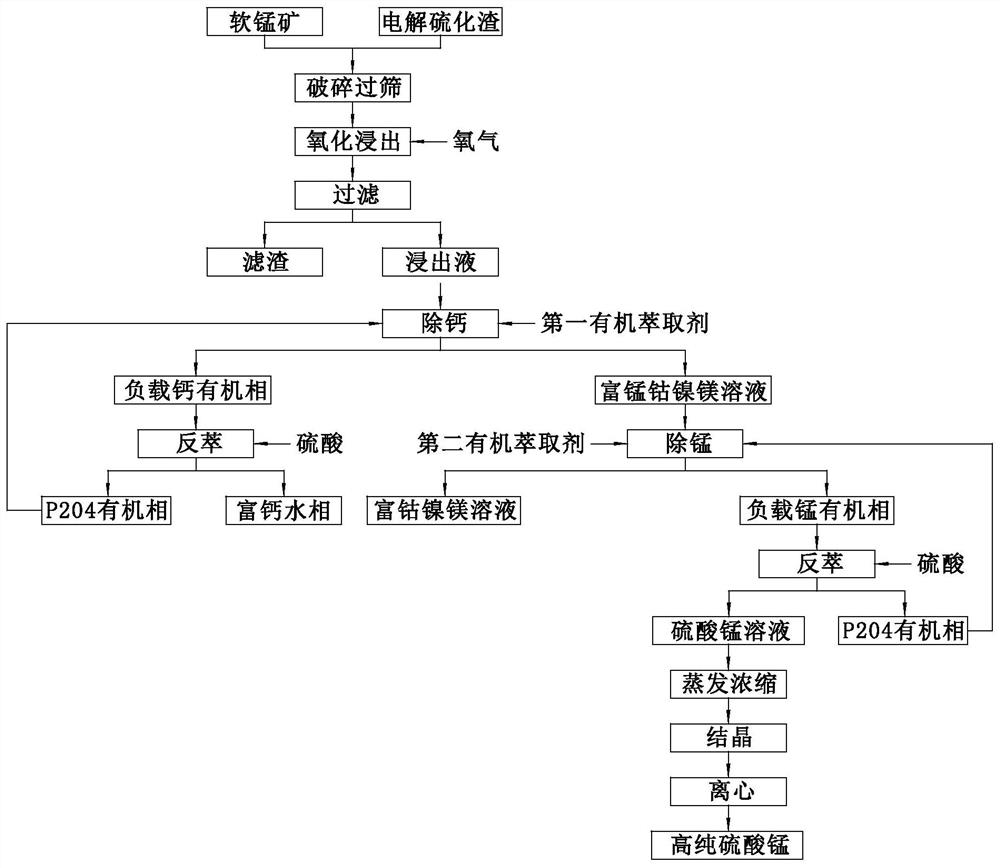

Method used

Image

Examples

preparation example Construction

[0038] (5) Preparation of high-purity manganese sulfate: get manganese sulfate solution to evaporate, concentrate, crystallize, and centrifuge to obtain high-purity manganese sulfate.

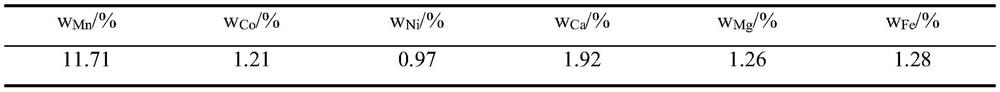

[0039] The composition detection of the electrolytic manganese sulfide slag adopted in the present invention is as shown in table 1:

[0040] Table 1

[0041]

[0042] According to the above method for preparing high-purity manganese sulfate, implement the following examples.

Embodiment 1

[0044] Crush and sieve 10g of electrolytic manganese sulfide slag and 17g of pyrolusite to 200 mesh, mix well, add 90g / L sulfuric acid solution according to the liquid-solid ratio of 10:1, feed oxygen 0.1Mpa, heat to 90°C, mechanically stir, and leaching 180min, the measured end point pH=3.0, filter, the leaching solution is adjusted to pH=0.5 with dilute sulfuric acid, and 30% P204+70% sulfonated kerosene is used to remove calcium according to the ratio O / A=1:1, wherein the saponification rate of the extractant is 20 %, extract for 10min, and then separate the liquid in a separating funnel to obtain a manganese-rich cobalt-nickel-magnesium solution after decalcification, then use sodium hydroxide to adjust the pH of the manganese-cobalt-nickel-magnesium solution to 3.5, and use 30% P204+70% sulfonation Kerosene is compared O / A=2:1 to the recovery of manganese-rich cobalt-nickel-magnesium solution manganese, wherein extractant saponification rate is 40%, extracts 10min, obtains...

Embodiment 2

[0046] Crush and sieve 10g of electrolytic manganese sulfide slag and 17g of pyrolusite to 200 mesh, mix well, add 90g / L sulfuric acid solution according to the liquid-solid ratio of 10:1, feed oxygen 0.2Mpa, heat to 90°C, mechanically stir, and leaching 180min, the measured end point pH=3.0, filtered, the leachate was adjusted to pH=1 with dilute sulfuric acid, and 20% P204+80% sulfonated kerosene was used to remove calcium according to the ratio O / A=1:1, wherein the saponification rate of the extractant was 30 %, extract 10min, and then separate liquids in a separating funnel to obtain a calcium-removing manganese-rich cobalt-nickel-magnesium solution, then use dilute sulfuric acid to adjust the pH of the water phase to 4.0, and use 30% P204+70% sulfonated kerosene according to O / A=2.5:1 reclaims manganese, wherein the extractant saponification rate is 30%, extracts for 10min, obtains the loaded manganese organic phase, and then uses 150g / L sulfuric acid to compare O / A=1:8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com