Recovery method of waste lithium iron phosphate positive electrode material

A technology of lithium iron phosphate and positive electrode materials, which is applied in the field of recycling waste lithium iron phosphate positive electrode materials, can solve the problems of environmental secondary pollution, environmental pollution, etc., and achieve the effects of small metal corrosion, avoiding secondary pollution, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

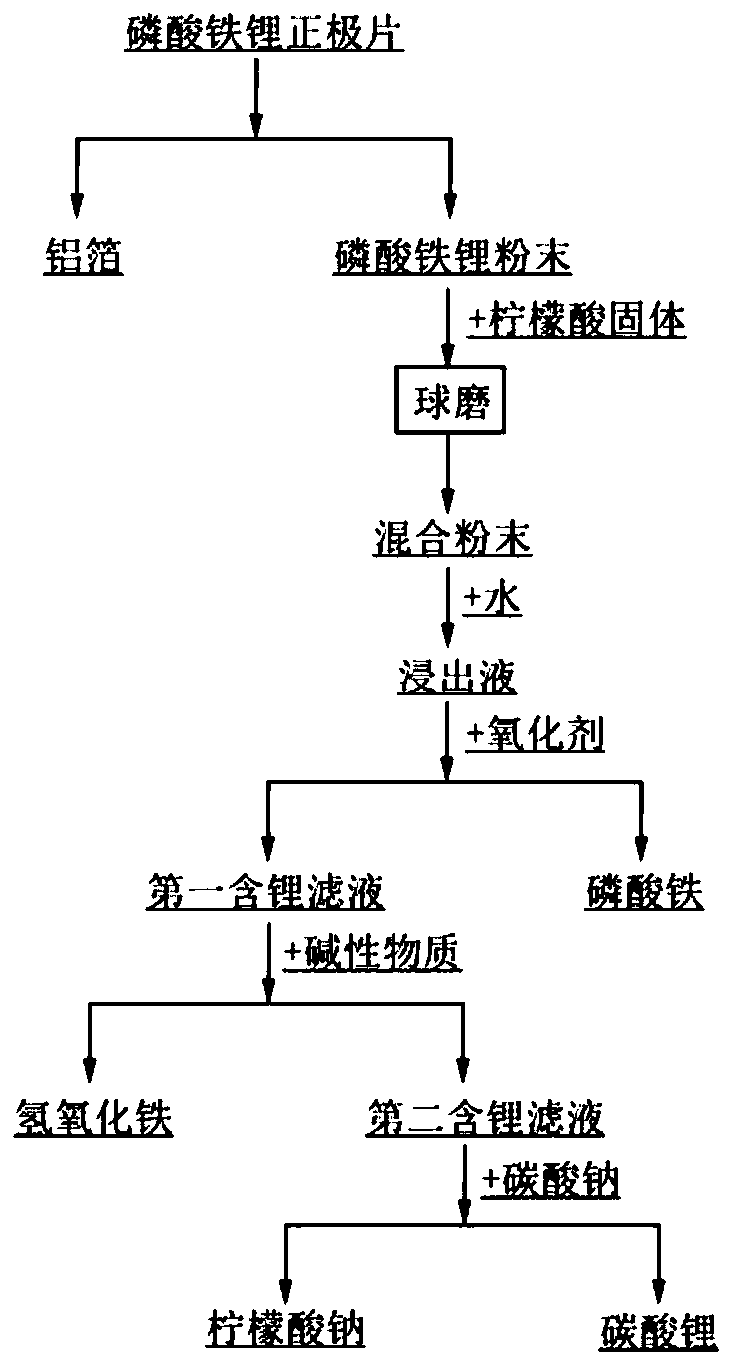

[0037]Embodiment 1 of the present invention is: a method for recycling waste lithium iron phosphate positive electrode materials, such as figure 1 shown, including the following steps:

[0038] (1) The positive electrode sheet obtained by dismantling the waste lithium iron phosphate battery is subjected to high-temperature roasting treatment, and after removing the binder and other components, the separated lithium iron phosphate powder and aluminum foil are obtained by sieving. According to a certain ratio, the obtained lithium iron phosphate powder is mixed with a solid grinding aid, and placed in a planetary ball mill for ball milling to obtain a mixed powder. The main purpose of this step is to use the energy generated by mechanical forces such as shearing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com