High-efficiency coupling, polygeneration and low-nitrogen coal gangue activation process

A technology of coal gangue and polygeneration, which is applied in the chemical industry, control/regulation process, inorganic chemistry, etc., can solve the problems of single coal gangue activation process, unfriendly environment, and low utilization rate of coal gangue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

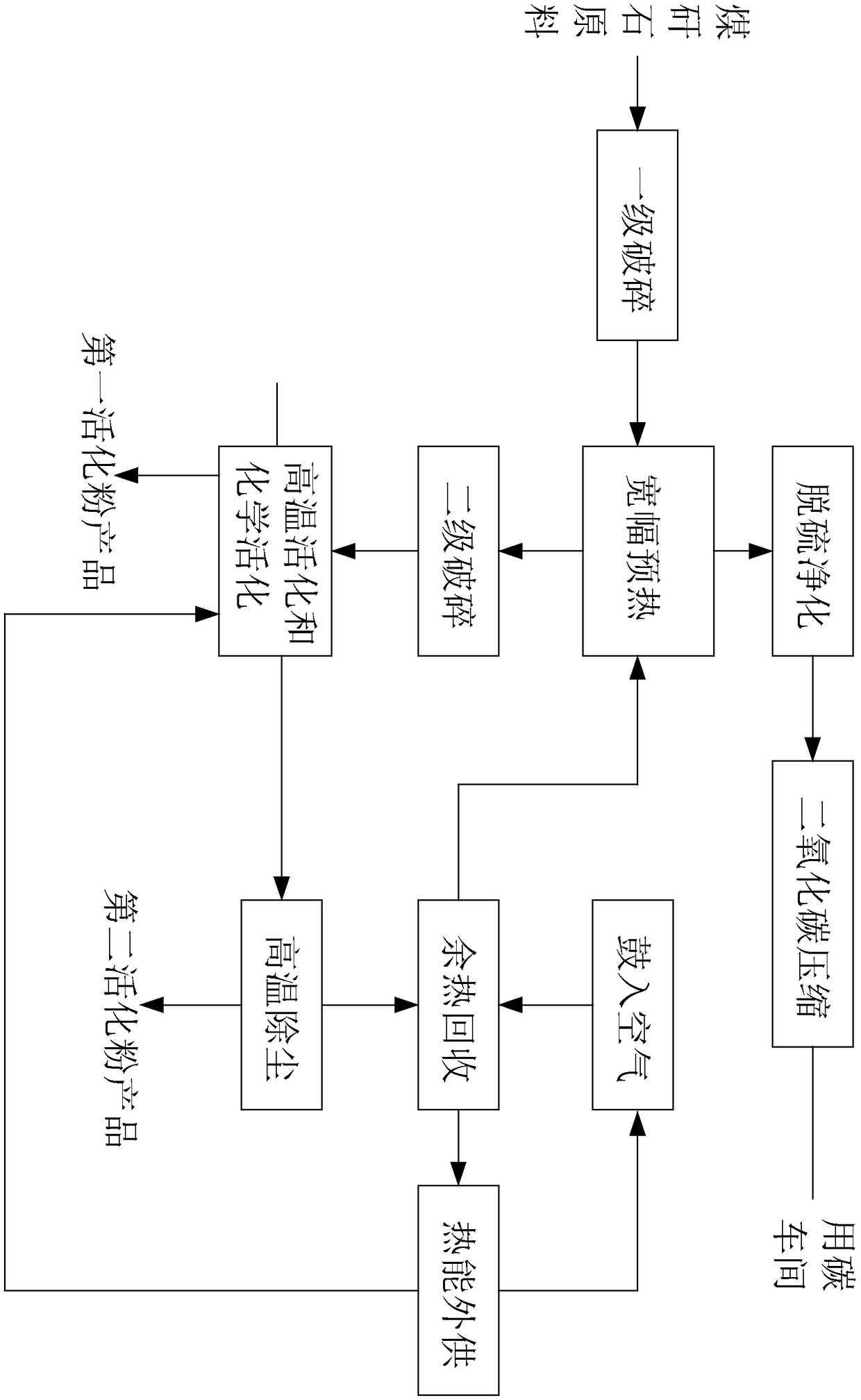

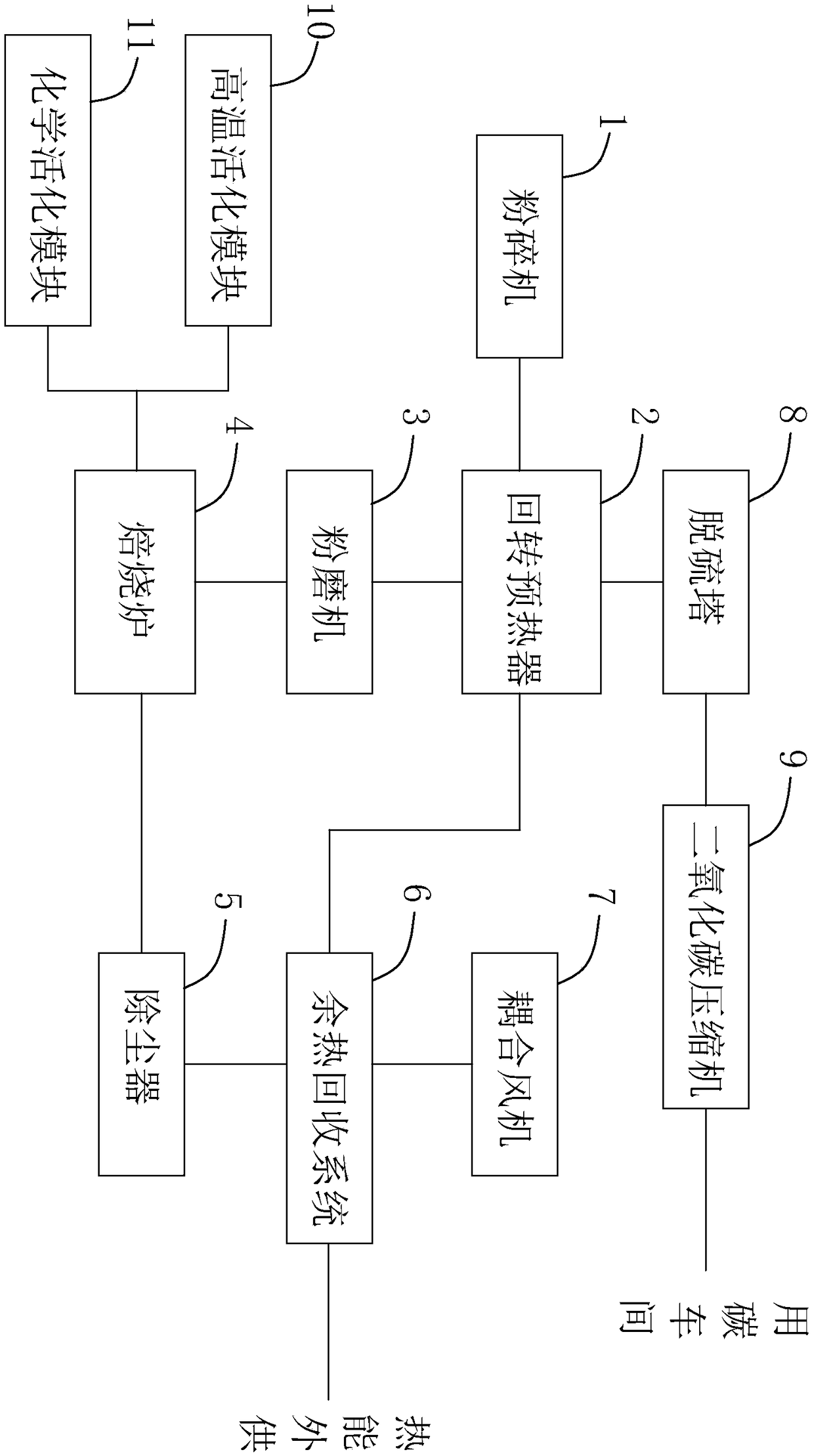

Method used

Image

Examples

Embodiment 1

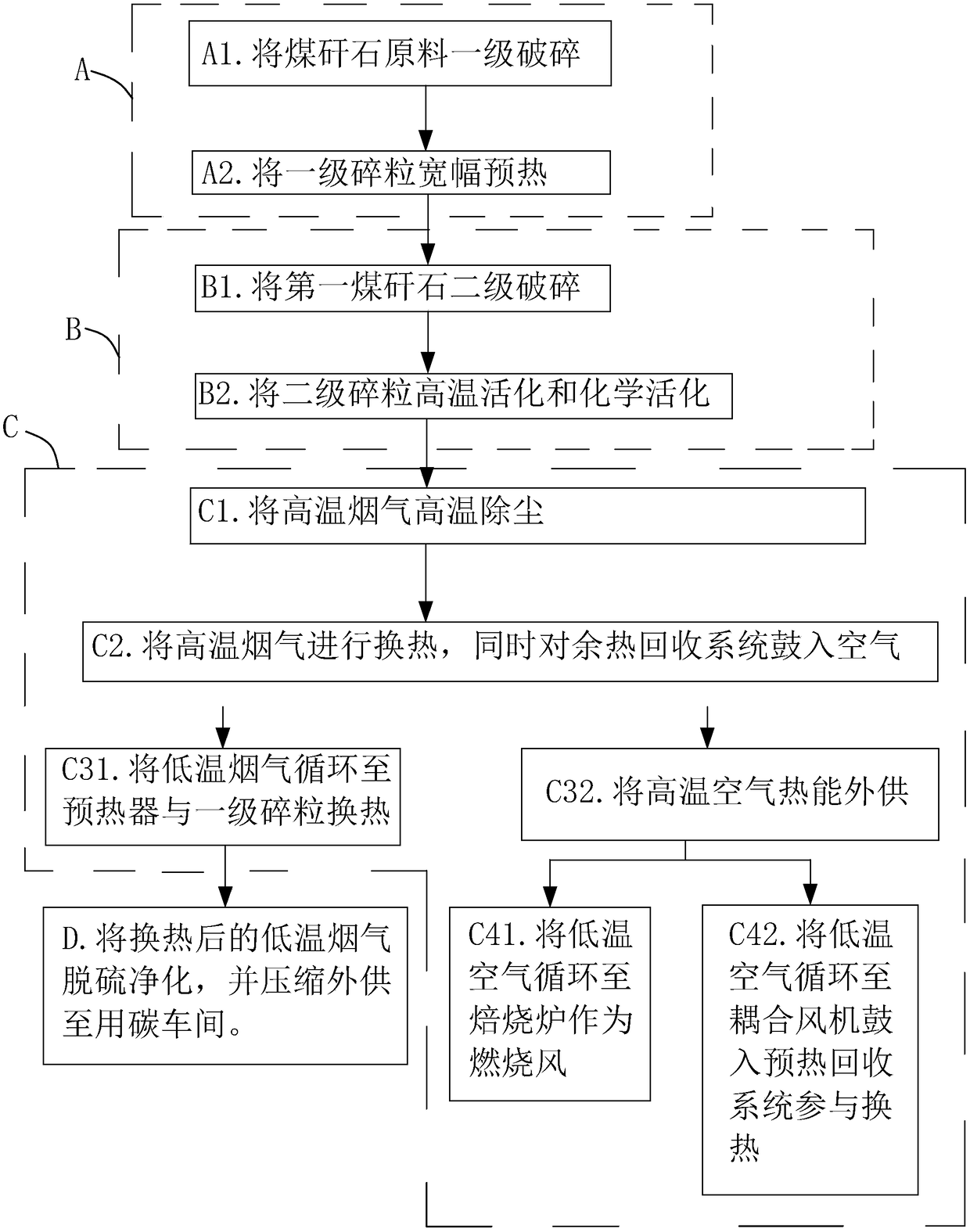

[0065] A high-efficiency coupling, multi-generation, low-nitrogen coal gangue activation process of this embodiment, the steps include:

[0066] Step A. Carrying out extensive preheating treatment of coal gangue raw material to obtain:

[0067] - The first coal gangue with a moisture content lower than 0.8%;

[0068] Specifically, the wide-width preheating treatment adopts the wide-width preheating technology of coal gangue: the coal gangue mined in the mining area is transported to the site, after preliminary crushing, it enters the rotary preheater, and the moisture content of the coal gangue is reduced. to below 0.8%.

[0069] Specifically, step A includes:

[0070] Step A1. The coal gangue raw material is subjected to primary crushing to obtain primary crushed particles with a particle size ranging from 20 mm to 50 mm; the particle size of the primary crushed particles in this embodiment is 20 mm.

[0071] Wherein, the primary crushing is carried out in the pulverizer 1...

Embodiment 2

[0108] A high-efficiency coupling, multi-generation, low-nitrogen coal gangue activation process of this embodiment, the steps include:

[0109] Step A. Carrying out extensive preheating treatment of coal gangue raw material to obtain:

[0110] - The first coal gangue with a moisture content lower than 0.8%;

[0111] Specifically, the wide-width preheating treatment adopts the wide-width preheating technology of coal gangue: the coal gangue mined in the mining area is transported to the site, after preliminary crushing, it enters the rotary preheater, and the moisture content of the coal gangue is reduced. to below 0.8%.

[0112] Specifically, step A includes:

[0113] Step A1. The coal gangue raw material is subjected to primary crushing to obtain primary crushed particles with a particle size ranging from 20 mm to 50 mm; the particle size of the primary crushed particles in this embodiment is 30 mm.

[0114] Wherein, the primary crushing is carried out in the pulverizer 1...

Embodiment 3

[0150] A high-efficiency coupling, multi-generation, low-nitrogen coal gangue activation process of this embodiment, the steps include:

[0151] Step A. Carrying out extensive preheating treatment of coal gangue raw material to obtain:

[0152] - The first coal gangue with a moisture content lower than 0.8%;

[0153]Specifically, the wide-width preheating treatment adopts the wide-width preheating technology of coal gangue: the coal gangue mined in the mining area is transported to the site, after preliminary crushing, it enters the rotary preheater, and the moisture content of the coal gangue is reduced. to below 0.8%.

[0154] Specifically, step A includes:

[0155] Step A1. The coal gangue raw material is subjected to primary crushing to obtain primary crushed particles with a particle size ranging from 20 mm to 50 mm; the particle size of the primary crushed particles in this embodiment is 50 mm.

[0156] Wherein, the primary crushing is carried out in the pulverizer 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com