A kind of vanadium-based material and its preparation method and application

A vanadium-based, positive electrode material technology, applied in nanotechnology, chemical instruments and methods, vanadium compounds, etc. for materials and surface science, can solve the problems of easy structure collapse and low cycle stability, and achieve improved capacity performance, Effect of Structural Stability Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

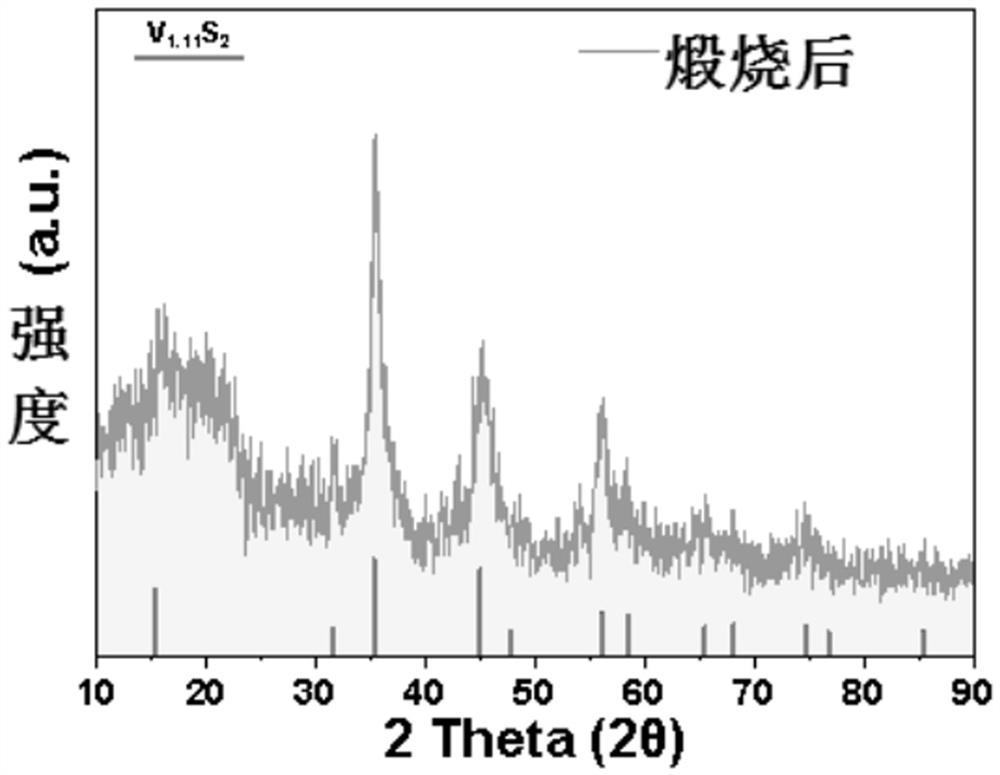

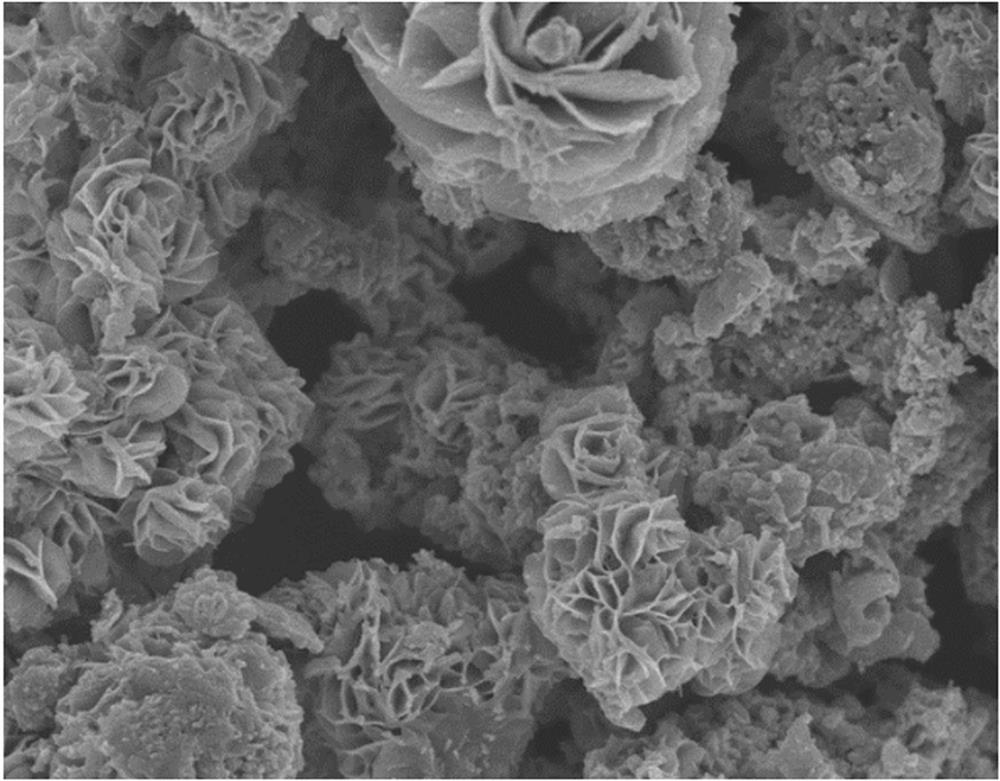

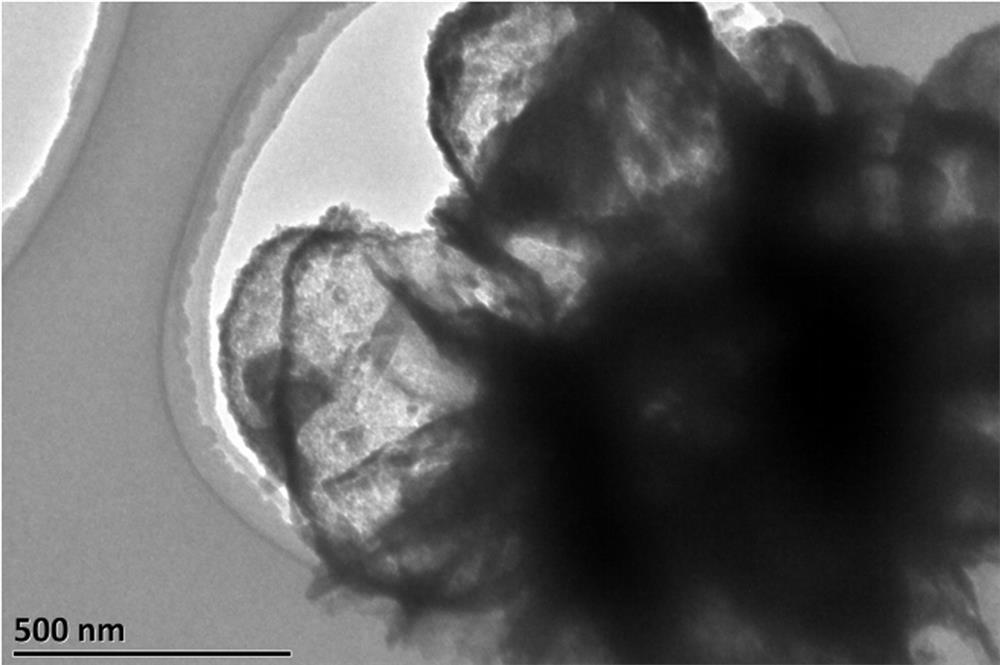

[0040] This example provides a vanadium-based material V 1.11 S 2 The preparation method comprises the following steps:

[0041] Step (1): 2 mmol ammonium metavanadate (NH 4 VO 3 ) and 10 mmol L-cysteine (L-cysteine) were added to 24 mL N-methylpyrrolidone (NMP), heated and stirred at 120 °C for 8 hours to obtain a mixture; then the mixture was transferred to a 50 mL poly In a tetrafluoroethylene-lined high-pressure reactor, react at 200 °C for 8 hours. After the reactor is cooled, take out the sample, and then wash it with deionized water and absolute ethanol three times respectively; put the cleaned sample into a vacuum Dry overnight in the oven to obtain the vanadium-sulfur intermediate compound;

[0042] Step (2): Put the vanadium-sulfur intermediate compound obtained in step (1) into a ceramic crucible under the protective atmosphere of argon gas, and calcinate it at 400 °C for 2 hours, and obtain a black sample after natural cooling, which is V 1.11 S 2 .

Embodiment 2

[0044] This example provides a vanadium-based material V 1.11 S 2 The difference between the preparation method and Example 1 is that ammonium metavanadate is adjusted to potassium metavanadate, and L-cysteine is adjusted to homocysteine; the remaining steps and parameters are the same.

Embodiment 3

[0046] This example provides a vanadium-based material V 1.11 S 2 The difference between the preparation method and Example 1 is that the amount of L-cysteine in step (1) is adjusted to 14 mmol, and the calcination temperature in step (2) is adjusted to 420 °C; the rest of the steps and parameters are the same .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com