Preparation method for high-stability cobalt neocaprate mixed salt

A cobalt neodecanoate, high stability technology, applied in the direction of non-polymer adhesive additives, adhesive additives, etc., can solve the problems of affecting the adhesion effect of rubber and steel cords, the decrease of cobalt content, and the increase of insoluble matter , to achieve the effects of increased content, reduced acidity, improved dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

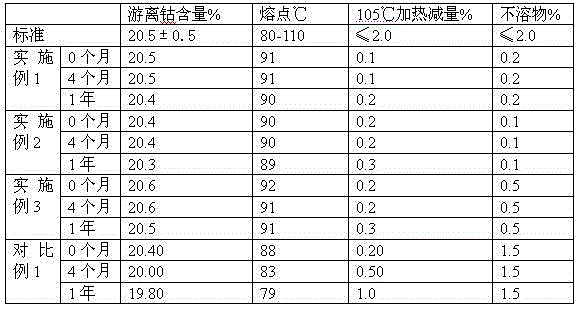

Embodiment 1

[0040] Step 1. Salt formation reaction

[0041] Put 27kg of cobalt hydroxide, 12kg of propionic acid and 45kg of neodecanoic acid into a sealed container at normal pressure, the temperature is 175°C~185°C, and the reaction time is 2.5 hours;

[0042] Step 2, acid displacement reaction

[0043] Add 18kg of isooctanoic acid and 6kg of stearic acid to the above reaction system, control the temperature at 190°C~200°C, and take 1.5 hours to replace propionic acid;

[0044] Step 3: Finished product

[0045] In the reaction system of step 2, the temperature is controlled at 200-210° C., and 7 kg of cobalt hydroxide is added as an auxiliary agent to prepare a high-stability cobalt neodecanoate mixed salt. Stir evenly for half an hour before discharging.

Embodiment 2

[0047] Step 1. Salt formation reaction

[0048] Put 25kg of cobalt hydroxide, 10kg of propionic acid and 50kg of neodecanoic acid into a sealed container at normal pressure, the temperature is 175°C~185°C, and the reaction time is 2 hours;

[0049] Step 2, acid displacement reaction

[0050] Add 15kg of isooctanoic acid and 5kg of stearic acid to the above reaction system, control the temperature at 190°C~200°C, and take 1.5 hours to react to replace propionic acid;

[0051] Step 3: Finished product

[0052] In the reaction system of step 2, the temperature is controlled at 200-210°C, and 5 kg of cobalt hydroxide is added as an auxiliary agent to prepare a highly stable cobalt neodecanoate mixed salt, and the mixture is stirred evenly for half an hour before discharging.

Embodiment 3

[0054]Step 1. Salt formation reaction

[0055] Put 28kg of cobalt hydroxide, 15kg of propionic acid and 50kg of neodecanoic acid into a sealed container at normal pressure, the temperature is 175°C~185°C, and the reaction time is 2.5 hours;

[0056] Step 2, acid displacement reaction

[0057] Add 20kg of isooctanoic acid and 8kg of stearic acid to the above reaction system, control the temperature at 190°C~200°C, and take 2 hours to react to replace propionic acid;

[0058] Step 3: Finished product

[0059] In the reaction system of step 2, the temperature is controlled at 200-210° C., and 8 kg of cobalt hydroxide is added as an auxiliary agent to prepare a high-stability cobalt neodecanoate mixed salt. Stir evenly for 1 hour before discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com