Preparation method of high-solid acrylic polyurethane coating

A technology of acrylic polyurethane and high solid content, which is applied in the direction of polyurea/polyurethane coatings and coatings, and can solve problems such as environmental unfriendliness, destruction of the earth's atmosphere and ecological environment, and human health damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

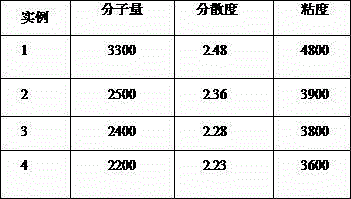

Examples

Embodiment 1

[0013] Add 0% glycidyl neodecanoate into the solvent of xylene and butyl acetate, blow in nitrogen, heat up to about 140°C, reflux for 10 minutes, and mix the monomer and part of the initiator solution evenly. Put it into the funnel and slowly add the mixed solution within 4.5 hours, then add the initiator tert-amyl peroxide as 2.5% of the total amount of monomers, and the chain transfer agent as 3% of the total amount of monomers, continue to stir and keep warm 1 hour.

Embodiment 2

[0015] Add 10% glycidyl neodecanoate into the solvent of xylene and butyl acetate, blow in nitrogen, heat up to about 140°C, reflux for 10 minutes, and mix the monomer and part of the initiator solution evenly. Put it into the funnel and slowly add the mixed solution within 4.5 hours, then add the initiator tert-amyl peroxide as 2.5% of the total amount of monomers, and the chain transfer agent as 3% of the total amount of monomers, continue to stir and keep warm 1 hour.

Embodiment 3

[0017] Add 20% glycidyl neodecanoate to the solvent of xylene and butyl acetate, blow in nitrogen, heat up to about 140°C, reflux for 10 minutes, and mix the monomer and part of the initiator solution evenly. Put it into the funnel and slowly add the mixed solution within 4.5 hours, then add the initiator tert-amyl peroxide as 2.5% of the total amount of monomers, and the chain transfer agent as 3% of the total amount of monomers, continue to stir and keep warm 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com