Non-stick electrolyte crust breaking hammer head for producing electrolytic aluminum

A technology of shelling hammer and electrolyte, which is applied in the field of electrolytic aluminum production equipment to achieve the effects of stable concentration, reduced labor intensity, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

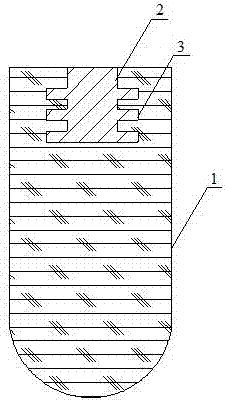

[0030] Such as figure 1 As shown, a non-stick electrolyte shelling hammer used for the production of electrolytic aluminum, the shelling hammer includes a hammer body 1 and a hammer handle 2 coaxially connected with a guide connecting rod. The guide connecting rod is connected with the shelling cylinder The connecting rod connected to the piston rod (omitted in the drawings), the material of the hammer handle 2 is suitable for meeting the temperature requirements above 960°C, the top of the hammer handle 2 is welded to the guide connecting rod, and the material of the hammer body 1 is High-purity graphite (carbon content of graphite >99.9%, the same below), high-purity graphite has the advantages of high strength, good thermal shock resistance, high temperature resistance, oxidation resistance, corrosion resistance, etc., and meets the process requirements of shelling. The head of the hammer body 1 is spherical, the hammer handle 2 is rod-shaped and the outer peripheral wall o...

Embodiment 2

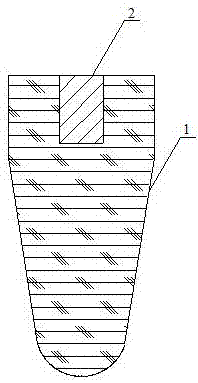

[0032] Such as figure 2 As shown, a non-stick electrolyte shelling hammer for the production of electrolytic aluminum, the shelling hammer includes a hammer body 1 and a hammer handle 2 coaxially connected with the guide connecting rod, and the material of the hammer body 1 is High purity graphite. The hammer handle 2 is rod-shaped, and the hammer body 1 is in the shape of a bullet as a whole. The hammer body 1 and the hammer handle 2 are arranged coaxially. Combined into one body, the hammer body 1 and the hammer handle 2 are combined into one body through threaded connection.

Embodiment 3

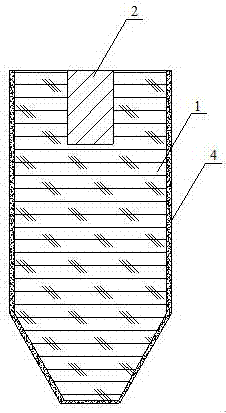

[0034] Such as image 3 As shown, the difference between embodiment 3 and embodiment 2 is that the hammer body 1 is made of amorphous carbon material, the head of the hammer body 1 is in the shape of a cone, and the hammer body 1 is coated with a composite coating 4. The composite coating is made by mixing 20-30 parts by weight of zirconia, 60-70 parts by weight of alumina and 3 parts by weight of aluminum dihydrogen phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com