Rubber torsional vibration damper with anti-static function

A torsional vibration damper and anti-static technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., to achieve good mechanical properties, increase tensile strength, and meet the effects of anti-static and damping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

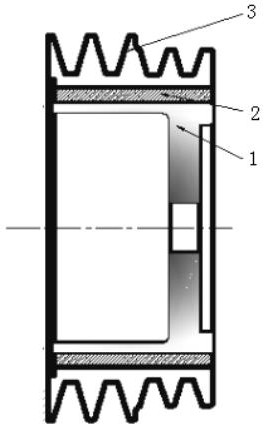

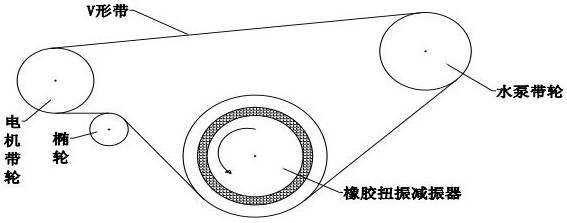

[0019] Embodiment: A rubber torsional vibration damper with antistatic function, comprising an inner wheel 1 , an outer wheel 3 and a rubber layer 2 arranged between the inner wheel 1 and the outer wheel 3 . The main materials and formulations of this embodiment are shown in Table 1. In the table: phr is the percentage mass unit content of the additive in the rubber, parts per hundreds of rubber (or resin).

[0020] Table 1

[0021]

[0022] The method for preparing the rubber layer with antistatic function of the present invention according to the formula of above-mentioned embodiment is as follows:

[0023] The equipment and instruments used are shown in Table 2.

[0024] Table 2

[0025]

[0026] The preparation process is:

[0027] a), kneading: masticating, kneading, extruding, calendering - masticating on the kneading machine for 2 minutes, adding vulcanization active agent (ZnO, SA), cutting knife left and right, dispersing for 2 minutes; adding small material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistance | aaaaa | aaaaa |

| Volume resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com